Pretreatments are designed to optimize corrosion protection and paint adhesion on manufactured parts. To better understand the equipment and processes needed to maintain spray patterns on a typical conveyor pretreatment wash system, manufacturers must first understand available nozzle technology, the variables that control spray patterns and the problems that clogged equipment can create over time.

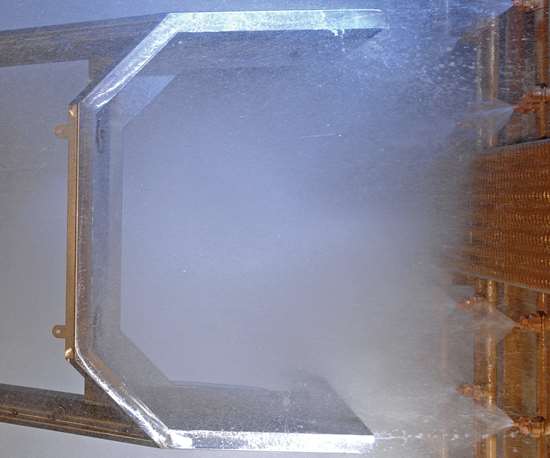

For optimal performance, substrates must be properly cleaned, rinsed and coated during the different stages of pretreatment. Each stage has a specific function and associated treatment chemistry, and each stage starts in the tank, where the chemistry is directed through a pump discharge to a header. The header then sends the chemistry into risers that feed the solution to the nozzles.

Featured Content

Nozzle selection is based on chemistry and application variables; each pretreatment stage requires a different nozzle type to ensure flawless application. Layout of the pretreatment system and size of the part being treated dictate the number of nozzles in the line, the size of the pump, the size of piping on the header and footer, and other variables.

A proper nozzle delivers the right amount of water or chemistry to the part’s surface, efficiently completing the task for that stage. Incorrect nozzle selection or improper spray patterns can increase the likelihood of defects and result in substandard product quality. As nozzles also influence impingement, an improper or clogged nozzle can lead to costly pretreatment downtime, or increase the amount of chemistry and water used.

For certain pretreatment processes, impingement is important to help remove soil from the part. However, pretreatment processes that involve coating or fully wetting-out the part require as little impingement as possible. Generally, a solid spray pattern provides greater impingement than a flat spray, and a flat spray provides greater impingement than full-cone sprays.

Measuring Impingement

Impingement is measured in units of force per area (newtons per square meter (N/m²) or pounds per square inch, (lbs./in.²). As with all spray patterns, unit impact decreases as the distance from the nozzle increases. Spray impact depends on the volumetric flow rate and the pressure drop.

A flat-spray nozzle typically should be used in the cleaning phase. This type of nozzle increases impingement on the part, creating a mechanical action. The increased physical impact on the part’s surface helps the chemistry to break down and lift the organic soil. The rinse after the cleaning stage should also be a flat-spray nozzle, as this type of nozzle helps to rinse off any residue from the cleaner.

Similar to cleaning, a flat spray during the acid pickle/deoxidizer phase increases impingement on the part and delivers scrubbing action. This physical movement on the part’s surface helps the chemistry to break down inorganic soil on the surface. The post-pickle/deoxidizer rinse should also use a flat-spray nozzle to rinse off the acid chemistry and prepare the surface for conversion coating.

Conversion coating requires a full-cone or hollow-cone nozzle, as the solution must flood over the entire substrate to allow for proper development of the coating layer. For the post-conversion coating rinse, a hollow- or full-cone nozzle removes unreacted solution without disturbing the newly formed coating. Post-treatment, the non-impinging spray of hollow- or full-cone nozzles allows a seal to form across the surface of the part. Normally, the rinse stage that follows sealing uses a full- or hollow-cone nozzle to flood the surface, removing unreacted seal solution.

Some systems have halo rinses at the end of the pretreatment process, while others have halos between stages. Halo rinses use a fine spray or mist nozzle linked to a clean water source to wet the entire surface and remove contamination and leftover chemistry.

Nozzles are made from a variety of metal and plastic materials. Pretreatment chemistry dictates the appropriate nozzle material for the process stage. If the nozzle material is incompatible with a stage’s chemistry and function, the nozzle may wear, clog or even corrode, creating unnecessary downtime and maintenance costs. For example, acids will rapidly destroy a mild steel nozzle, while stainless steel will provide a long service life when exposed to acids.

Worn nozzles are a significant cause of system waste. As a nozzle wears, the orifice gets larger, so the nozzle outputs twice the amount of liquid. Impingement decreases, reducing the pressure of the spray at the point of impact. This diminishes the performance of alkaline cleaners and may increase the volume of cleaner used. As greater volumes of solution are sprayed from the worn nozzle, spray pressure decreases for other nozzles on that riser.

Controlling Spray Patterns

Nozzles direct pretreatment solutions at the parts being processed, and correct spray nozzle alignment and spacing provides full, uniform coverage to the entire part. The design of the process line dictates the number of nozzles required for optimal application.

Nozzles on opposite risers should alternate position so the pretreatment solution covers the entire area of a part but spray patterns do not merge. If spray patterns merge, the part will experience reduced impingement. Nozzles for flat sprays should be turned approximately 15 degrees from vertical. When properly aligned, the spray pattern will not interfere with the adjacent nozzle’s spray pattern.

Part orientation also plays a crucial role in controlling spray patterns. Parts are put onto a fixture or frame that escorts the part through the pretreatment process. The fixture rides on a chain and ideally allows all working areas of the part to be exposed to pretreatment solutions. Orientation of the part on the frame influences the placement and amount of solution applied to the part.

Line operators should check nozzle spray patterns frequently throughout production. Visual checks examine the part, solution exiting into the drain zone and spray coming out of the nozzles. However, many nozzles cannot be observed while production is running. By walking the pretreatment line when it is stopped, operators can check nozzle spray direction, inspect all the housings in the pretreatment zone and check that the correct nozzles are used in each phase.

Inspection of clean parts should show consistently wet surfaces across the part. After rinses, the part should be water-break free, displaying an even, wet surface that will not allow water to bead up. After conversion coating, the coating should be evenly distributed across the part with no blotchy areas or water breaks. Uneven coating distribution on multiple parts may indicate a plugged or misaligned spray nozzle. Streaks or patterns are also good indicators of process issues.

Monitoring Pressure Gages

The pressure gage on the pump discharge, located close to the pump, should be monitored regularly throughout pretreatment. If pressure drops, there may be a split riser or nozzle issue. If pressure rises, there may be a clog in a riser or in several nozzles.

Built-up debris in the nozzle will reduce spray pressure, volume of chemistry delivered and location of spray on the part. Scale can clog nozzles, leading to insufficient cleaning, coating and rinsing processes, and, ultimately, to poor paint adhesion. Cleaning or coating failures on consistent sides on several parts in succession indicate a problem with clogged nozzles.

Using sharp objects to dislodge materials from clogged nozzles may damage the orifice, affecting spray patterns. Operators should remove the clogged nozzle and place it in cleaning solution, replacing the clogged part with a clean nozzle.

Drain zones should appear consistent throughout production. An increase in the amount of foam or solution in the drain zone may indicate that a nozzle has blown off or that there is a cracked riser.

Spray patterns should also be consistent. If solution sprayed from the nozzle collects in errant locations rather than being contained within the stage, or if solution is spraying out of the nozzle in a stream rather than a fan pattern, the nozzle may be plugged or misaligned and should be checked.

To ensure correct pressure and direction, operators can remove nozzles from the risers during a tank clean-out to inspect orifices for debris and O-rings, rubber rings seated between the nozzle and the riser, for damage. Bad O-rings can cause pressure to drop, leading to improper impingement.

Once nozzles are off, operators can remove the riser end caps and flush the system with tank cleaning solution and follow up with a clean-water flush. If nozzles are left in place, debris generated by tank cleaning can clog them. During the cleaning process, side walls, the floor and chain guards should also be cleaned and rinsed.

Cost to Operate

The No. 1 driver for optimizing and maintaining spray patterns in the wash system is cost to the operation. Expenses can accrue from chemical and water waste, quality issues, unplanned shutdowns, and water-treatment requirements.

Quality issues may be discovered during manufacturing or by the end user as warranty problems. Chemical, manpower and energy resources are wasted when parts do not pass inspection after their first treatment, requiring expensive rework. Delayed adhesion failure and corrosion, occurring when the part is in use, is especially costly as thousands of parts may have been manufactured before the defect is detected, effecting customer satisfaction and future sales.

Unplanned manufacturing line shutdowns are also a concern, causing work to back up and creating extra manpower costs. By building spare quick-disconnect risers, clip-on nozzles and pumps in anticipation of line failure, manufacturers can minimize downtime, installing replacements quickly and reducing shutdown costs.

When pretreatment systems perform optimally, water and chemistry are used efficiently, with little flowing to waste treatment. Exhaust system malfunctions, lost chemicals, and health and safety concerns will be minimized. Effective management and maintenance of spray patterns and pretreatment process lines deliver high-quality parts and control operation costs. By performing frequent maintenance checks, manufacturers can minimize the costs of pretreatment process systems.

Matthew Clark is a manager and application engineer at Henkel Corp. Visit bonderite.com.

RELATED CONTENT

-

Preventing Solvent Pop

Preventing solvent pop on an industrial paint line...

-

Quality Finishing: Don’t Starve Your Spray Gun for Air!

Tips to Avoid Pressure Drop in Air Spraying

-

Pretreatment for Painting

Better adhesion, enhanced corrosion and blister resistance, and reduced coating-part interactions make pretreatment a must.