Share

Process tanks are a necessity, providing critical service to plating and pickling operations, yet they have often been implicated in facility accidents, leaks, catastrophes and fires. Associated risks can threaten both worker safety and groundwater contamination, draining profit and a company’s reputation.

It is said that a prudent man learns from his experience but a wise man learns from the experience of others, and the intent of this article is to provide you, the reader, with the opportunity to become wiser without experiencing your own major loss. Rather than focus on technical or scientific issues, we will share actual experiences we have encountered over the past 40 years in the finishing industry.

Since no “silver bullet” tank material exists, and any tank is only as good as its weakest element, tanks should not be viewed as a commodity nor taken for granted. About 75 percent of process tank users have reported experiencing tank leaks. Proper material selection, and taking advantage of advances in fabrication/welding methods and technologies can greatly reduce premature failure.

Exposure and Environmental Liability

Although tank leaks can often be repaired, the associated lost production and loss of chemicals can be costly. In a recent survey, 67 percent of facilities reported having had a leak that resulted in major cost or burden, and 18 percent have experienced catastrophic tank failure in the past. These latter companies reported dire consequences: worker exposure, overcoming of secondary containment, and environmental or clean-up liability.

Poor welding is a common cause of tank failure. Welding machines provide the highest strength welds, and plastic shops should have quality assurance programs and qualified welders based on AWS b2.4 standard specification for plastic welding. Hand welds are tedious and require intense focus, and since welding large tanks requires long hours or days of welding, tiredness and reduced concentration are likely. The fewer hand welds—both in terms of linear feet and number of passes—the better.

But tank welds are not the only source of tank failure. In one instance, a well-built seven-year-old polypropylene tank that had never leaked before experienced a side wall blowout due to hidden structural steel corrosion caused by acid drips at the tank’s top rim. A fume collection hood had been mounted on the tank rim, and the plastic encapsulating the steel structure evidently had been compromised. Hot fumes will condense to liquid, and even extremely slow drips will amount to gallons of acid over time. One drip per minute equals one gallon per week (364 gallons over seven years), so even one drip per hour over seven years would create six gallons of acid. In this case, the actual quantity it took to dissolve the steel is irrelevant; whatever the amount, it was enough to fully corrode the steel

Fortunately, this incident happened over a weekend, when no one was near the heated tank full of acid. Had someone been on the catwalk next to the tank when the wall blowout occurred, we can only imagine the consequences.

Suggestions for Preventing Similar Catastrophes

We offer the following suggestions for preventing a similar catastrophe:

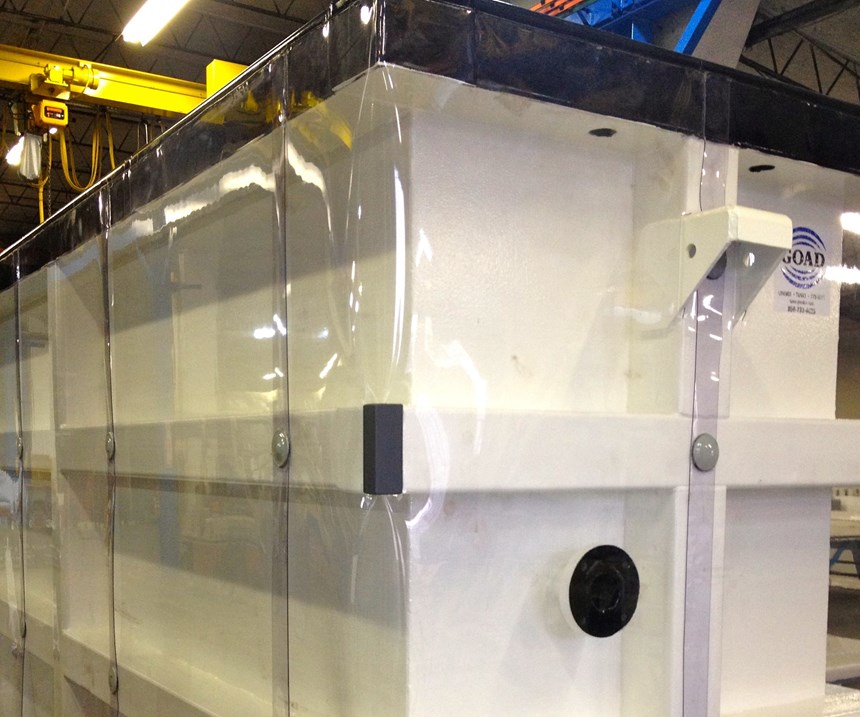

- Monitor the deflection or bowing of tank walls. Use a laser measurement device and shoot the laser beam from one end of the wall to its other end. If you have to move out from the edge to get to the other end, that distance represents how much the wall has deflected or bowed. Full tanks want to be round, so structure is required to stiffen the wall, and without structure (see images), the plastic itself can break apart. Note that the tank needs to be filled to its operating level in order for the deflection to be properly measured.

- Visually inspect the integrity of the structural steel itself. This may sound easy to do, but often a visual inspection is not possible because the steel is encapsulated in plastic to prevent it from corroding from chemical splashes or from the atmosphere itself. In addition, if lateral hoods or a catwalk or other items are at the tank, the deflection described above may be difficult to measure. Spark testing may be a possibility, and DC spark testing, rather than AC spark testing, is the safest method, but it requires grounding to the steel, which complicates matters. Another option (except in the case of stainless steel) is to use a large on/off welding magnet to check if the mild steel has been eaten away. If the steel is still there, a strong magnet will connect to it, even through the plastic encapsulation.

- Consider using solid-wall steel tanks over free-standing plastic tanks with an encapsulated structure. Steel tanks can have either a patented bonded lining (no problematic hand welds with seam strips) or a machine-welded box liner dropped into it. We have never heard of this type of tank experiencing a complete wall blowout. The steel exterior can be lined, which allows for easy spark testing, or covered with a clear, see-through vinyl that protects the steel yet allows visual inspection for corrosion.

Polypropylene Tanks Rated Worst

In a discussion of tank catastrophes, we would be remiss if we did not address plastic tank fires. When we started fabricating machine-built polypropylene (PPL) tanks in the early 1980s, we thought they were great, and so did our customers—until a devastating process line fire at a captive shop. It turns out, of 30 plastics tested, polypropylene was rated the worst in terms of fire hazard. PPL has been called “diesel fuel in the solid state,” because it is almost all hydrocarbon, and it burns with a maximum heat-release rate approaching that of gasoline. Temperatures as high as 1,093°C (2,000°F) are reached, sufficient to cause steel to lose strength and for buildings to collapse. Plus, firefighting is made more complex by the presence of hazardous materials. Some plants have been a total loss.

Loss-prevention data sheets from FM Global Property recommend using “noncombustible construction for all pickling and electroplating tanks, fume collection and exhaust equipment, and ducts.” The requirements for fire protection sprinkler systems, hose streams (500 gallons per minute), water supplies, alarms and interlocks, containment systems, and minimum one-hour fire separation between combustible plastic tanks and the surrounding occupancy are exhaustive, costly and stringent.

Polyvinyl chloride (PVC), chlorinated PVC (CPVC) and polyvinylidene fluoride (PVDF) all offer excellent fire properties, as they are among the least easily ignitable plastics and are self-extinguishing; they will not continue burning unless a large, continuous heat source is applied to them. They also have low flame-spread ratings due to drastically lower heat-release ratings. Tests have shown that burning PPL releases 14 times more heat than burning PVC.

Avoiding Human Error

Of course, the ever-present human element can result in tank failures, too. Here are some examples we have encountered:

- A worker added air at the inlet of a slow-draining plastic cylinder in a treatment system to speed up the draining, only to have the vessel burst from the added pressure.

- A large, steel-lined zinc-nickel plating tank lost all of its precious contents when it was accidentally drained. Frank Altmayer, educational director of the National Association for Surface Finishing, advises against drain valves in plating tanks.

- A PVDF tank, which earns it place as among the best for acid service, is repurposed for a high-pH solution—its Achilles heel—and fails. Don’t assume a great tank can hold any solution; instead rely on the expertise of your supplier.

- An anodizer was using a caustic etch tank along with a domed side tank to collect and separate the sludge. The etch solution produced a large amount of foam containing hydrogen gas, which accumulated in the dome of the tank; only a small pipe ventilated the dome. A spark from an unknown source at the etch tank (probably metal against metal from the hoist work bar) set off the hydrogen in the foam, and the clarification tank took off like a rocket, blasted through the wall of the building and landed in the parking lot, flattening an unoccupied car.

Our advice is this: Please learn from the experiences and catastrophic failures of others; be wiser because of their losses and not your own.

Curtis Goad is president of Goad Co. Visit goadco.com.

Related Content

NASF/AESF Foundation Research Project #120: Electrochemical Destruction of Perfluorooctanesulfonate in Electroplating Wastewaters – January – December 2023

This NASF-AESF Foundation research project report covers quarterly reporting for the year 2023 at the University of Illinois at Chicago. The objective of this work is to utilize a cost-effective reactive electrochemical membrane (REM) for the removal of PFAS from synthetic electroplating wastewater. Discussed here are the oxidation of PFOA with three different catalysts, development of a method for detecting PFAS, as well as work on 6:2-fluorotelomersulfonic acid (6:2 FTS) and electrodeposited bismuth/tin oxide catalysts.

Read MoreAir Pollution Control Equipment, Ventilation Ensures Quality Workplace Conditions

SUR/FIN 2025: Crossair strives to build clean air managements with reliable performance that meet customer requirements and comply with EPA and OSHA regulations.

Read MoreCeramic Media Filters Out Metals for Less

A low-cost alternative to legacy technologies, this ceramic molecular media filtration system removes metals and pollutants from industrial wastewaters at a low price point.

Read MoreExplore Cleaning Chemistry, Metal Finishing Applications and Wastewater Treatment Solutions

Hubbard-Hall Celebrating 175 years of excellence, Hubbard-Hall presents chemistry and equipment.

Read MoreRead Next

Reducing Material Use and Overspray

Looking for applicators or process improvements for reducing material use and overspray? Binks offers helpful advice for searching out new solutions.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read More