Selective plating, also known as brush plating, is already a widely used method of surface enhancement with well-known benefits. The process involves applying high-quality electrolyte solutions and precision anodes onto localized areas of components, minimizing waste and environmental impacts compared to more comprehensive processes.

Selective plating is operator-intensive, however, with skilled individuals remaining close to the work area throughout the process to handle chemicals and tooling. Automation can minimize the need for operator intervention, making the process safer and more consistent. An intricate system using a power pack, pumps, valves, anodes and solutions works together, prepping, changing, catching, plating and then circulating the plating solution.

An operator-programmed computer program then controls the volts, amps, polarity and ampere-hours required for the specific application, including pre-treatment and plating steps.

For high-wear, high-competition industries like the power generation industry, this technology can improve outcomes through increased throughput, quality and accuracy; reduced downtime; and lower costs.

Improving Efficiency in the Power Generation Industry

Powell Electrical Systems Inc. has benefited from automating its copper bus bar selective plating process, reducing the process time by 90% and saving around $100,000 in annual labor costs.

Copper bus bars play an important role in conducting electricity through distribution networks within the power generation industry. These components must meet an exacting standard that permits carrying very high currents across mating bus connections with minimal contact resistance. The industry practice to decrease electrical contact resistance at mating bus connections is to electroplate them with a suitable material such as silver or tin before installing them in the system.

A typical bus bar has four distinct faces requiring electroplating. Prior to installing a semi-automated workstation from SIFCO ASC, Powell completed this manual process one face at a time with an operator moving a hand-held plating anode tool back and forth across the surface being plated until achieving the desired silver thickness. Thickness was often inconsistent because the operator needed to err on the upper side of tolerance, and plating was a lengthy 21-minute process.

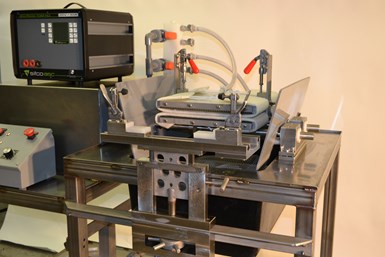

The semi-automated dual plating workstation SIFCO ASC designed for Powell was the first of its kind for this type of application. With the workstation, Powell could selectively silver plate both sides of the copper bus bars simultaneously and achieve the desired plating thickness uniformly, consistently and efficiently.

Reducing process time saved Powell around $100,000 annually, while increasing the quality of the company’s finished products. Photo Credit: SIFCO ASC

“The whole copper bar processing line has multiple potential bottlenecks,” Jessica Heuel, quality assurance engineer at Powell, said. “Being able to significantly reduce the plating operation time has helped remove electroplating as a potential bottleneck in our process, which allows the workers to assemble the bus duct much faster.” Heuel also reports the quality of Powell’s selective-plated pieces has increased as a result of adopting SIFCO ASC’s automated system.

This bespoke workstation reduces the electroplating process time from 21 minutes to just two minutes, saving approximately $100,000 worth of labor costs annually when Powell’s power generation unit is operating at full capacity. Powell’s efficiency gains, quality increases and savings since the first installation have even prompted the company to purchase a second machine.

Discovering the Possibilities of Automated Selective Plating

In a practical example, automated selective plating is especially useful for high-wear, constant-operation industries like power generation because it can ensure repairs are completed in a timely manner during scheduled downtime periods.

Along with silver plating on bus bars, other common selective plating applications include pre-brazing of turbine blades and vanes and applying nickel-plated deposits onto high-wear surfaces such as outer diameters (ODs) and inner diameters (IDs) of components like bearings and housings. With the introduction of digitalization to the process, operators can also implement full component and process traceability through constant system data monitoring.

An automated approach also opens up opportunities for improved sustainability. Robotic equipment both works around-the-clock and utilizes only the exact volume of chemicals required at each stage of the selective plating process – effectively reducing the thickness range in the specification. In turn, waste – and environmental impact – is significantly reduced when automating selective plating and repairs of selective-plated components.

Related Content

SPS Atlanta 2025 Addresses Manufacturing Challenges With Automation-Focused Solutions, Dynamic Education Programs

Taking place September 16-18, 2025, at the Georgia World Congress Center, the U.S. debut of Smart Production Solutions (SPS Atlanta) offers a focused platform to drive automation forward and reinforce American industrial strength.

Read MoreUnlock Unparallelled Reliability

By prioritizing reliability in every aspect of its service offerings Dynapower ensures your equipment operates at peak performance levels consistently. With a steadfast focus on reliability, Dynapower’s field service, preventative maintenance and spare parts solutions ensure uninterrupted operations, minimizing scrap and maximizing uptime.

Read MoreTake Action to Mitigate Cyber Threats Before It’s Too Late

Cybersecurity is increasingly becoming a concern for all companies. Stay alert and heed these pointers for avoiding data breaches and other network and online disruptions that can be detrimental to your shop.

Read MoreAI Tool Optimizes, Automates Powder Coating

New “digital Blueprint” technology fine-tunes every aspect of a powder coating system. The platform promises at least 10% powder savings, a return on investment of a few days and an increase in uptime.

Read MoreRead Next

Reducing Material Use and Overspray

Looking for applicators or process improvements for reducing material use and overspray? Binks offers helpful advice for searching out new solutions.

Read MoreAlkaline Cleaning Guide

Gregg Sanko, Senior Chemist, Oakite Products, Inc. provides an overview of the alkaline cleaning process.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read More