Modeling Software Improves Understanding of Porous Coatings

University of Illinois at Chicago leverages SwiftComp software to predict elastic and mechanical properties of porous coatings under different loading conditions.

Share

Read Next

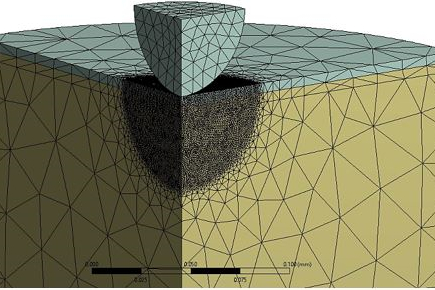

Coating/substrate structure under a nanoindentation tip to measure the mechanical response of the component. Photo Credit: AnalySwift LLC

AnalySwift, LLC (West Lafayette, Ind.), a provider of efficient high-fidelity modeling software for composites, has announced that University of Illinois at Chicago (UIC) is participating in its Academic Partner Program (APP), and it is using its SwiftComp simulation software for researching new porous coatings for use in manufacturing. The APP offers participating universities no-cost licenses of engineering software programs SwiftComp and VABS so students, researchers, and faculty can leverage the tools in their academic research.

The SwiftComp program is a general-purpose, truly multiscale modeling code for composites and other heterogenous materials. It links detailed microstructure and structural behavior for composite structures including beams, plates/shells, and 3D structures. Broad applications include high strain composites in deployable space structures, printed circuit boards (PCBs), high-end fishing rods, honeycomb sandwich structures, and many others. In this instance the software was used to analyze the performance of Zirconia-Silica conversion coatings.

“We used the Mechanics of Structure Genome concept, implemented in SwiftComp, to calculate the effective elastic and mechanical properties of porous coatings under different loading conditions,” said Dr. Arash Samaei, researcher at the UIC Accelerated Materials Research Lab (AMRL). “The test case for our study was Zirconia- Silica bilayer coating on aluminum alloy. The simulation results enabled us to understand the effects of porosity level on the strength of the macroscale structure. The local stress, strain fields helped us to study the failure mechanisms in such coatings under nanoindentation tips. SwiftComp allowed us to determine the effective properties of the materials that enabled us to accurately simulate the mechanical response of the components.”

“In general, Zirconia-Silica conversion coatings are considered as a potential alternative to Chromium-based conversion coatings, which are fabricated with toxic chemicals,” continued Dr. Samaei. “Not only can zirconia-silica-based conversion coatings provide excellent corrosion protection for metals and alloys used in aerospace applications, but they can also be manufactured using non-toxic chemicals via a plasma-based deposition process.”

Related Content

-

Products Finishing Reveals 2024 Qualifying Top Shops

PF reveals the qualifying shops in its annual Top Shops Benchmarking Survey — a program designed to offer shops insights into their overall performance in the industry.

-

How to Choose a Paint Spray Gun

Application speed, improved transfer efficiency and finish quality are essential characteristics to consider when searching for the best liquid paint spray gun for an application.

-

Top Shop Aims to Reshape Aerospace Finishing in Florida

By blending legacy finishing expertise with new heat treat and painting operations, Incertec is taking off in a fast-growing aerospace market. Business acquisitions have boosted its emergence onto a path to success.