When veteran inventors Mike Bunnell and Daryl Bruischat put their minds together to build a better mousetrap for the drying and curing of waterborne CARC paints, they both hoped to come up with a system that might change the industry somewhat.

What they didn’t count on were the unusual—and often “bizarre”—steps it took to get to their new curing process utilizing sophisticated dehumidification and humidification, which they are marketing under the name Atmosphere Control Solutions.

They say the new system using humidity control plus engineered air flow will cut drying and curing time from as much as 12 hrs to roughly 90 min—an 85-percent improvement—and still pass all military requirements. Plus, they say it reduces or eliminates VOC and HAP emissions.

“Effective control of the drying process is the key to achieving an acceptable finish with waterborne paint,” Bunnell says.

Outside-the-Box Thinking

Bruischat goes a step further in describing the combination paint booth and drying system that could set you back roughly $900,000: “It truly is revolutionary. We really thought outside the box.”

Bunnell, a grizzled veteran of the finishing industry and president of

Can-Am Engineered Products Inc. in Livonia, Mich., had made turbine powered liquid spray guns and systems, fluid regulators, and fluid and turbine air manifolds for decades before deciding to come up with a solution for a quicker way to dry and cure CARC paint used by the military to protect its vehicles from corrosion and chemical attack.

Bruischat is an accomplished engineer who designs environmentally controlled testing facilities, laboratories and test chambers in Holland, Mich.

When they started working together two years ago on the project, after being introduced by a mutual friend, they both followed standard engineering, chemistry and physics laws to try to cut the drying and curing time and make a “greener” product.

Solvent-based paints cure faster than waterborne applications, which makes going green a harder choice because of the additional time it takes to properly to meet specifications.

Back to the Drawing Board

When they started to see no progress on what was already on the market, Bunnell and Bruischat went back to the drawing board and started to ask friends and colleagues for some advice. Bruischat says some of his engineering and chemistry friends opened his eyes to unique approaches.

They started tinkering with the ideal of baking a finish for a short time after a coating application, then immersing the parts in a humidity-controlled climate for about an hour, shooting about 600 gal of water into hot air to rapidly cure the coating. They followed with another 20 min of baking.

“We subjected the parts to ‘near-rain’ conditions to remove moisture from the coating and cure it,” Bunnell says.

Yes, add water to remove water and cure.

“It’s bizarre,” Bruischat says. “We went almost 180 degrees from what we were originally thinking. To take moisture out, you add moisture. It’s like turning left to go right. We looked at each other and said, ‘Are you kidding me?’”

But does it work? Bunnell and Bruischat say it passes all military tests with flying colors, especially the strict methyl ethyl ketone(MEK) rub test, which requires taking a cotton cheesecloth soaked with MEK and rubbing a finish for 100 stroke cycles to see if failure occurs, meaning the CARC coating is penetrated down to the primer coat.

Passing the MEK Test

Bruischat says their tests showed no failure at double the requirements: 200 stroke cycles.

“Nothing came off,” he says.

The Atmosphere Control Solutions system is offered in three ways:

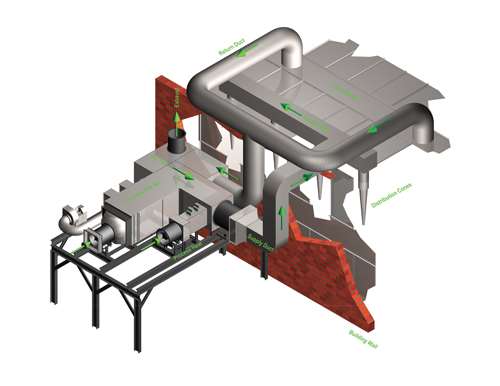

- A Combo System that includes Phase I painting in a progressive multi-stage filtration that delivers 98 percent efficiency at 0.3 microns, followed by Phase II drying where the product is left in place after painting to dry and avoids double handling.

- A Batch System that consists of a static enclosure providing a closed envelope for drying product or parts, which can be fitted with racks, shelves or fixtures to hold parts or product to be dried.

- A Continuous System featuring a dynamic enclosure of horizontal or vertical design for curing of moving parts.

But even though Bunnell and Bruischat say they can prove they save time and energy while delivering a product that meets specs, the big question is, who will buy their better mousetrap?

“It’s a tough market out there right now,” Bruischat says. “Things are as dried up as the desert, so we’ve talked with some military people and they are very interested, but everything seems to have ground to a halt purchasing wise.”

Quick ROI

Despite a $900,000 price tag for the system, but both Bunnell and Bruischat say that the ROI on the process is returned fairly quickly, considering the savings in energy and time, and the fewer environmental concerns.

“The military is definitely interested in our process, and we could have four to five bases looking at using it,” Bunnell says. “There are also the fleet operations that we have had some discussions with. I think proving that it works well is a good start, and that they can get it down to operating at about $32 an hour in the military is a great advantage.”

Bruischat says that, as they roll out the product to a few buyers, he thinks the momentum will pick up and the process will become popular. Other markets they plan to reach are general industrial finishers, wood and automotive OEMs, and the auto-body and truck repair markets.

“Painting is very much a ‘show me’ type industry,” he says. “It does work, and it will save a huge amount of time and money. Everyone is resistant to change, but we think this will catch on in a big way, especially as waterborne becomes more mandated.”

For more information on Atmosphere Control Solutions, please call 800-229-7551 or email info@atmosphere-control.com.

RELATED CONTENT

-

E-coat can produce uniform finishes with excellent coverage and outstanding corrosion resistance.

-

Joseph Subda, ecoat specialist for Axalta Coating Systems, explains the difference between these two corrosion resistance tests.

-

A more realistic way to perform salt spray tests.