Aluminum Anodizer Implements Zero Liquid Discharge

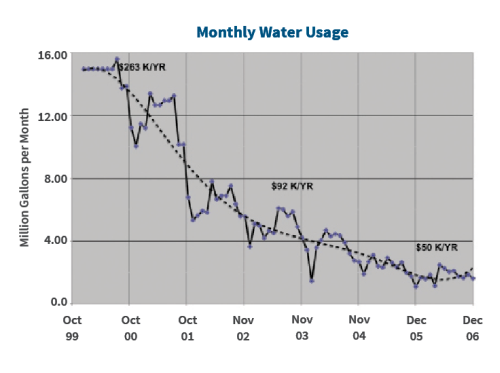

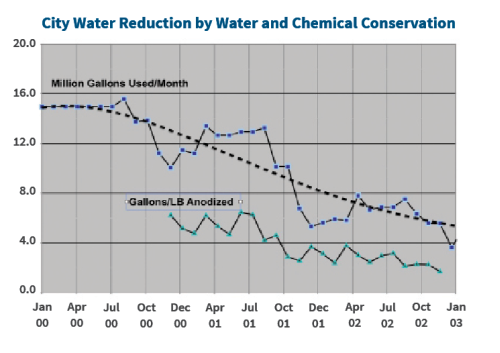

Success of water minimization reuse at Bonnell Aluminum in Georgia after implementing zero liquid discharge facility for aluminum anodizers.

Bonnell Aluminum is an aluminum extrusion and anodizing operation in Newnan, Georgia. Prior to 2005, wastewater from the operation was treated with conventional chemical precipitation consisting of neutralization, flocculation and clarification. Effluent was discharged into a zero-flow stream and toxicity tests indicated that salts in the effluent could be harmful to water organisms. Bonnell evaluated methods to reduce the toxicity—later deciding to treat and reuse the effluent.

Featured Content

The company encountered many challenges when implementing one of the first zero liquid discharge (ZLD) facilities for aluminum anodizers, which led to 10 years of successful ZLD facility operation. Key results of the operation were:

Investing in a holistic approach for pollution prevention, water conservation and wastewater treatment and reuse;

Changing the wet process to reduce the water usage and reduce the advanced wastewater treatment system;

- A project environmentally, rather than economically, justified;

- 85 percent reduction in city water use;

- Savings of $230,000 per year in city water purchases;

- Maintenance of a high-quality aluminum product with water reuse;

- And reductions in the National Pollutant Discharge Elimination System (NPDES) permit requirements.

Reasons for Changes and Challenges

In 2000, biotesting of Bonnell’s NPDES outfall consistently indicated toxicity to water organisms in the zero-flow stream that received the company’s treated wastewater. The high dissolved solids level in the wastewater (primarily sodium sulfate) was the suspected primary toxin. The NPDES permit was due for renewal and something had to be done about the toxicity of the treated wastewater.

Some of the challenges the company faced included an extremely high flow of wastewater (just under half a million gallons per day), high levels of dissolved solids in treated water, varying compositions of wastewater into treatment, high production demands and the need for a cost-effective solution due to business conditions. The strategy selected dealt with each challenge.

The premise at the beginning of the project was that water conservation at the Newnan plant was possible and would be more cost effective because it would reduce the size of the wastewater treatment system. For conventional wastewater treatment facilities, the cost of equipment is proportional to the logarithm of flow rate. However, for advanced treatment where water is recovered and reused, the equipment cost is proportional to flow rate. Thus, it was imperative for the company to reduce the water usage.

Bonnell compared the water usage at Newnan to usage at its plant in Carthage and concluded that reducing usage at Newnan would be feasible.

Plant management in Newnan was committed to pollution prevention and addressing water use issues. The plant manager appointed the anodizing manager to oversee a team inside the plant. The team included a project engineer, a design team arranged by the division environmental manager, consultants and, eventually, equipment suppliers. Every team member was committed to the project effort.

An EPA waste minimization paper benchmarked Bonnell’s progress with its focus on water conservation technologies.

The company conducted many activities to reduce water use in anodizing, including:

- Collecting data on the rinse tanks in each of the two anodizing lines, monitoring conductivity, pH and flow of water (this was helpful in the redesign of counterflow rinse systems);

- Aerating rinse tanks to improve rinsing efficiency;

- Placing timers on the cranes used in anodizing to “pause” the rails of extrusions being removed from process tanks, forcing liquid to be drained back into the tanks, conserving chemicals and rinse water;

- And installing low-flow water sprays to “wipe” parts when lifted from rinse tanks.

As water use was being reduced, options for treatment, recovery and reuse were considered.

Bonnell evaluated a number of different options, including a city sewage facility treatment, reverse osmosis (RO) and several end-of-pipe treatment schemes. The company had worked with the local publicly owned treatment works, but even with reduced wastewater, this option offered little hope. Bonnell piloted an RO unit operated out of a trailer on site, which provided useful information. Then, end-of-pipe treatments were tested. A small test plot of wetlands was installed and bench work with peat moss and other media was pursued. These options varied in effectiveness with none showing great success.

Plant management at Bonnell was committed to pollution prevention and the water use issue.

The New Treatment System

The design team selected DMP Corp. of Rock Hill, South Carolina, for the recovery/reuse project. The company joined the team and detailed design began.

It was clear the cost of reuse and recovery equipment would be reduced if the dissolved solids were also reduced, so chemical precipitation was implemented as the first treatment process. The dissolved solids in the treated wastewater were the result of neutralizing sulfuric acid waste streams with sodium hydroxide, either from alkaline waste streams or from storage tanks. Sodium sulfate is very soluble, though few alkalis produce salts that will precipitate above certain concentrations. Lime (calcium hydroxide), an inexpensive alkali, reacts with sulfuric acid to produce calcium sulfate, or gypsum. This compound precipitates above 2,500 parts per million (roughly), thus removing some of the sulfates from the waste stream.

The waste streams were segregated into acidic waste streams and non-acidic waste streams. The more acidic waste streams were collected into segregated acid streams (SAS) and nonacid streams (NAS). The SAS stream contained sulfuric acid content from 1.5 to 2 percent. Dilute acids and alkaline streams were directed to the NAS system. The SAS wastewater was neutralized with lime to a pH of around 5. The precipitate calcium sulfate was then flocculated and removed in a clarifier and thickener. The resulting pH 5 stream then joined the NAS wastewater, but with a reduced dissolved solids content.

The treatment system involves the SAS and further treatment before RO. The NAS waters are treated to remove metals and hardness through soda ash softening and precipitation at two pH levels: pH 10 and pH 7. This treatment removes calcium, magnesium, nickel and other metals that precipitate at pH 10 and the aluminum is removed at pH 7. Each stage of treatment includes two-stage neutralization, flocculation and clarification.

Prior to 2005, the wastewater from the anodizing operations was treated by conventional chemical precipitation consisting of neutralization, flocculation and clarification.

Prior to RO, the treated waters go through carbon adsorption, bag filtration and ion exchange as a polishing step to remove metals, calcium and magnesium.

The membrane system involved three trains, each with two stages of membranes.

The evaporator is a double effect, steam-heated, vacuum-operated unit. The stainless steel evaporator operates at 80 percent recovery and the only real moving part is a centrifugal pump. Air pressure transfers distillate and brine.

|

Operating pressure |

Up to 600 psi |

|

Recovery |

85% |

|

Capacity |

125 gpm |

|

Conductivity permeate |

<450 (µS/cm) |

|

Reject stream |

35,000 µS/cm at 7–8 gpm |

|

Permeate sent back to manufacturing along with distillate from evaporator. |

|

Results

Many changes have occurred at the Newnan plant in the last 10 years.

- The two anodizing lines were consolidated into one line not long after the startup of the water recycle system.

- A change in anodizing necessitated removal of ammonia from the distillate using a stripper.

- Heaters were installed for the feed to the RO unit due to drops in recovery by the unit during winter months. By maintaining a constant inlet temperature, membrane performance is optimized.

- Scaling is an ongoing issue with the NAS system and the SAS treatment system. Jetting of lines is needed every few months to maintain flow rates.

Bonnell implemented one of the first zero liquid discharge (ZLD) facilities for aluminum anodizers.

The system has been operating for more than ten years. Permeate and distillate are reused and the reuse water meets the design goal, unless there is a failure with the RO membranes. The short life of the RO membranes—between one and two years—is the biggest problem Bonnell has experienced. The brine, containing sodium sulfate salts, is shipped off site for treatment. Water use has been reduced by 85 percent since 2000.

Bonnell discovered that minimal water use in anodizing can be achieved without sacrificing quality. Leadership from plant management, tracking conductivities in anodizing, improving rinsing and installing crane drainage systems are some effective techniques for water savings.

Membrane systems can be effective, but may or may not be cost justified. For Bonnell, the justification was environmental and necessary for survival. City water may be needed in one or two rinses, but reusing water is feasible.

George Patrick is with Arcadis; Loren McCune is the retired environmental manager from Bonnell Aluminum. This paper was presented at the 2015 Anodizing Conference. For more information, visit bonlalum.com and arcadis.com.

Originally published in June 2016.

RELATED CONTENT

-

How to Apply the 720 Rule to Current Density Anodizing

What can you tell me about the 720 Rule as it applies to current density anodizing? Plating expert Sjon Westre, Ph.D., from Chemeon, answers this question.

-

Fixing Corrosion Between Anodized Aluminum and Steel

Anne Deacon Juhl, Ph.D., with AluConsult, says Galvanic corrosion is due to an electrical contact with a more noble metal or a nonmetallic conductor in a conductive environment.

-

Deoxidizing Aluminum as a Pretreatment

This important first step can help prepare the metal for subsequent surface finishing.