Expanding Custom Work Enables Top Shop to Shine

This six-person shop rallies together to offer diverse finishing jobs that are growing to include custom show parts for automobiles and motorcycles.

#military

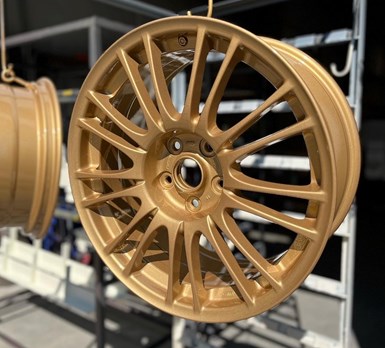

BK Industrial is becoming more diversified in the custom motorcycle and truck show arena. This is an sample of the custom work the shop is doing. Photo Credits: BK Industrial

When Barry Kendall quit his job in 1990 to begin his own finishing company out of a chicken coop and with no customers, he was aware of the risk and not aware of the success he would soon experience. With his entrepreneurial spirit and love of creating finished products, he went on to build BK Industrial Finishing from only grossing $1,500 in the business’s first year to dramatically increasing that number every year over the next several years and since then, has continued to be profitable. In fact, over the past three years, the Merrimack, New Hampshire, company has enjoyed a 25% growth rate, according to Kendall.

He attributes the company’s success to his dedicated and skilled employees as well as the business’s willingness to perform work that many other shops cannot do or will not do, he says.

Featured Content

While BK Industrial is becoming more diversified in the custom motorcycle and truck show arena, the company has become a leader in finishing and coatings for the U.S. military and defense contracts, offering such finishes as chemical agent resistant coating (CARC), powder coatings, conductive and non-conductive coatings, stealth, and radar-resistant coatings. The shop also provides light assembly, silk screening, sand blasting, masking, RFI coatings and spray painting.

A colorful customer base

Along with doing work for the U.S. Army, Navy, Marines, Air Force and Department of Defense, the company has an array of customers that include

This purple snowmobile chassis is a sample of the custom design work BK Industrial has been doing lately.

Major League Baseball and the National Basketball Association, as it finishes the seating at several sports stadiums across the U.S. The shop also works for industries such as sheet metal manufacturing, medical and plastics.

Kendall describes the diverse work his company has completed. “We’ve done jobs from 10-foot-wide printers to custom motorcycles, as well as a lot of snowmobile parts.”

His son, Barry Jr., who is vice president of the company and has taken over most of the daily operations, has been pushing the company’s involvement in the custom motorcycle/truck business and work that is sponsored by large corporations, Kendall explains. Taking on this custom work has contributed to a 25% increase in the shop’s growth over the past three years.

Barry Jr. says some of these newer customers originate from frustrations with “hack shops” that do poor-quality work by taking cost-saving shortcuts. Companies come to BK Industrial after leaving those shops with custom car wheels and truck parts that they are looking to be showcased but do not live up to quality standards, Barry Jr. explains.

The power of excellent employees

Companies come to BK Industrial after leaving shops with custom car wheels and truck parts that they are looking to be showcased but do not live up to quality standards.

As a qualifying Products Finishing Top Shop for multiple years running, BK Industrial’s employees are to thank for these recognitions. Kendall says his staff takes pride in their craft to provide quality and efficiency to every customer. “You are only as good as your employees,” he says. And at this six-person shop, this statement is especially true because it leaves no room for slack from even one employee. The company philosophy is instilled in each employee: “If you wouldn’t buy it, don’t ask our customers to.”

While upholding high standards, Kendall values his employees and focuses on retention. Understanding that respected staff are loyal staff, he listens to their ideas for improvement. If an alternative way to do a process is discovered and it is cost-effective, he says he hopes his staff members will share their input with him.

“I still learn something every day from my employees,” he says. “You have to value their opinions and thoughts.”

RELATED CONTENT

-

Changing From Liquid to Powder Coating

Will the powder coating perform better than your liquid system? Products Finishing columnist Rodger Talbert discusses considerations you should consider when making the switch.

-

Powder Coating Week 2024 Offers Education and Networking

On March 11-13, 2024, this event for powder coaters will combine training, presentations, technical sessions, tabletop exhibits, roundtable discussions, expert panels and social activities.

-

Surface Preparation for Best Adhesion for Powder Coating

Kevin Biller with ChemQuest recommends the proper way to prepare a surface for powder coating that leads to excellent adhesion on 304SST.