Protective Coatings for Fuel Elements Prevent Accidents in Nuclear Reactors

Shells can significantly reduce hydrogenation of containers where nuclear fuel is placed, extend their service life and protect reactors from explosion in case of potential accidents.

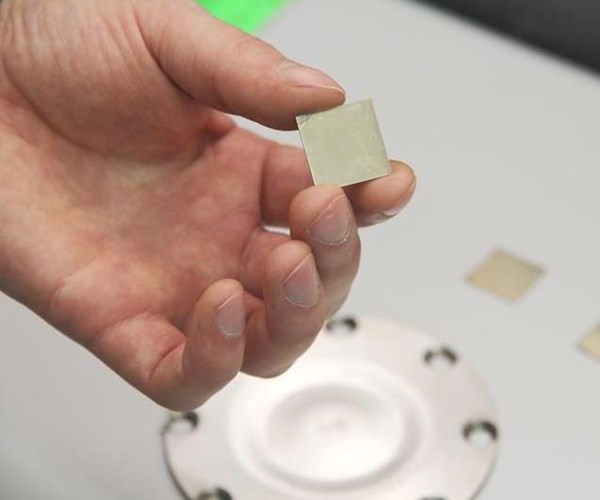

A sample of the titanium nitride-based coating. (Photo: Tomsk Polytechnic University)

Research done by a team from the general physics department at Russia's Tomsk Polytechnic University (TPU) is designing protective titanium nitride-based coatings for shells of fuel elements used in nuclear reactors.

Featured Content

The shells can significantly reduce hydrogenation of containers where nuclear fuel is placed, extend their service life and protect reactors from explosion in case of potential accidents.

“In order to form fuel rods within any reactor nuclear fuel is laid in special “tubes” out of zirconium alloys. A nuclear reaction takes place in the fuel rods. As a result of radiolysis of a reactor coolant – water, and due to interaction of the coolant and zirconium under high temperatures hydrogen is released. In such fuel rods shells hydrogen is able to accumulate causing degradation of their mechanical properties and destruction,”says Egor Kashkarov, an assistant in the department.

According to Kashkarov, the higher the temperature in the reactor is, the more hydrogen is released which is caused by the interaction of zirconium and water. For example, the same happened at the Fukusima-1 station in Japan: due to flooding of pumping equipment the active zone of the reactor warmed up to more than 1,200 degrees, a steam-zirconium reaction proceeded swiftly and a large amount of hydrogen was released. The explosion of accumulated hydrogen was one of the causes of the biggest radiation accidents in the world.

The research team from the TPU Department of General Physics is designing protective titanium nitride-based coatings that will serve a barrier protecting zirconium fuel rods from water and hydrogen accumulation.

To read more, please click HERE.

RELATED CONTENT

-

A Chromium Plating Overview

An overview of decorative and hard chromium electroplating processes.

-

Smut and Desmutting

Question: I am new to this industry and have heard about smut and desmutting operations.

-

Masking for Surface Finishing

Masking is employed in most any metal finishing operation where only a specifically defined area of the surface of a part must be exposed to a process. Conversely, masking may be employed on a surface where treatment is either not required or must be avoided. This article covers the many aspects of masking for metal finishing, including applications, methods and the various types of masking employed.