Reducing VOCs

Coating materials (paint and solvent) are one of the most significant sources of VOC generation. John Owed of Carlisle Fluid Technologies offers advice for reducing VOC consumption.

#asktheexpert #regulation #sustainability

Q: Our company is working to strengthen our corporate Environmental, Social and Governance (ESG) goals. I have been asked to identify opportunities within our liquid finishing process to assist. Specifically, I would like to identify areas where we can reduce energy and coating usage.

A: The paint-finishing process is a target-rich environment for identifying opportunities to reduce energy and VOC consumption. From an energy perspective, compressed air is one of a manufacturing facility’s most expensive energy sources. Coating materials (paint and solvent) are one of the most costly consumables and the most significant source of VOC generation. Focusing on these two areas should provide a substantial contribution to establishing goals.

Featured Content

A U.S. Department of Energy survey showed that for a typical industrial facility, approximately 10 - 30% of the electricity consumed is used to generate compressed air. Some very simple and more involved methods exist to reduce compressed air consumption. Simple methods include shutting off the compressor when unnecessary and repairing air leaks. Although it is not feasible to shut down a compressor in some cases, advanced controls and variable speed compressors are available to manage overall air usage based on varied demand throughout the day/week. Compressed air loss from leaks can be considerable depending on maintenance and the age of the system.

Advancements in the electrification of the painted kitchen can also aid in reducing compressed air consumption. Electrically operated pumps designed for use within the paint mix room can yield a 70 – 80% reduction in energy usage by eliminating compressed air. Since the pumps are electrically controlled, additional benefits can be achieved with overall management of the paint circulation system by reducing the circulation rate when there is no demand for a specific color.

This reduces the shear on the coating and can improve overall performance from an appearance perspective.

For companies not ready to convert to electric pump technology, an audit of the existing fluid delivery equipment can also yield savings by ensuring the pumps are properly sized based on pressure and flow demands. Additional savings can be found by reviewing the accessories used within the finishing process. We had an experience with a large industrial user that had 100 agitators in use to keep materials in suspension. The agitators were of an older vein-style design that consumed much compressed air. Upgrading to a more efficient rotary piston agitator design reduced their air consumption by 65%, resulting in an annual savings of $120,000.

Relative to coating usage, the best way to reduce VOC consumption is to ensure that the most transfer-efficient applicator technology for the process is being used. Trends in OEM and Tier 1 facilities have been to use electrostatic rotary atomizer technology over legacy air spray and or air spray electrostatic applicators. In addition to yielding higher transfer efficiency based on lower atomized particle velocity, rotary atomizers produce a more uniform spray pattern that yields a finish with an overall better appearance.

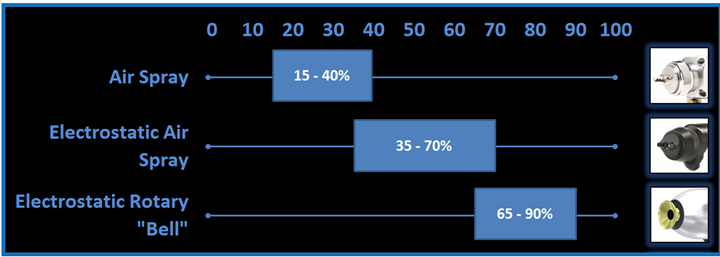

Chart 1: Typical transfer efficiency range of applicator atomization technology. Source: Carlisle Fluid Technologies

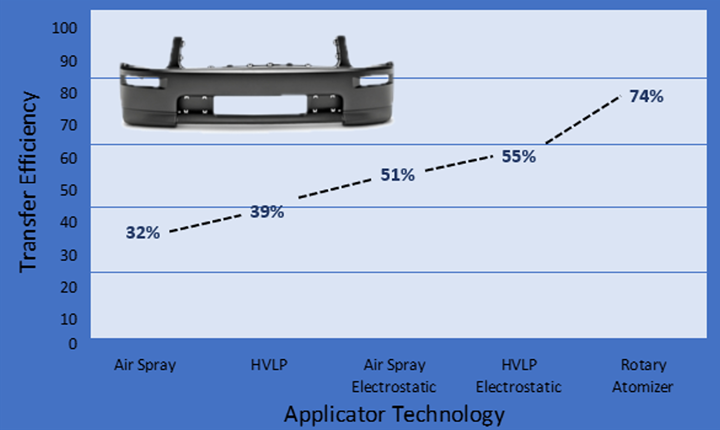

Referencing chart #1 shows that traditional air spray technology yields a transfer efficiency (TE) of 15 – 40%, electrostatic air spray technology a TE of 35 – 70%, and rotary atomizers a TE of 65 – 90%. Chart #2 illustrates the results of various lab trials where actual TE was empirically measured, proving the advantage of rotary atomizer technology in yielding greater efficiency that directly reduces overall coating usage/VOCs.

Chart 2: Testing data of applicator atomization technology and related transfer efficiency.

To summarize, focusing on compressed air usage and coating consumption can provide immediate results if you are looking for opportunities to reduce energy and VOC consumption in your finishing process.

About the Author

John Owed

John Owed is the finishing SBU director at Carlisle Fluid Technologies. Visit carlisleft.com.

RELATED CONTENT

-

Removing Cured Powder Coatings

Question: What methods are available for removing cured powder coatings, and what are the pros and cons of these methods?

-

Preventing Anodizing Cathodes from Turning Red

While the red color may not be desirable, anodizing expert Drew Nosti says it poses no particular problem to a successful anodizing process.

-

Cleaning, Pretreatment to Meet Medical Specs ISO 13485 or FDA 21 CFR820

Maximilian Kessler from SurTec explains new practices for industrial parts cleaning, metal pretreatment and decorative electroplating in the medical device industry.