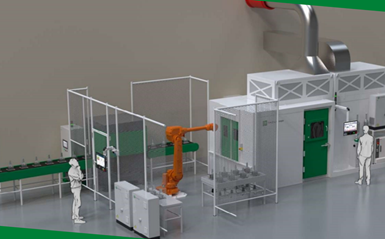

Automated Production Cells Comes in 3 Standard Configurations

The Coating Machine comes in three different configurations while enabling enough freedom to fit customer specific needs.

Edited by

Photo Credit: Flame Spray Technologies, Daes Group

Flame Spray Technologies, a partner of the Daes Group, has developed The Coating Machine — a compact automated production cell that comes in three standard configurations to provide the freedom to fit customer-specific needs in a variety of markets. Type I features a turntable and robot; Type II features a carousel and robot; and Type III features a spray lathe and robot combination. The continuous operation provided by the technology is said to provide increased production rates when compared to conventional spray systems.

The Coating Machine is designed for less operator involvement while quality is checked and safeguarded. Because of the continuous running and the use of integrated flame sensor technology, the company says there is increased quality and a reduction in rejected parts.

According to the company, The Coating Machine has no process limitation — all thermal spray processes can be incorporated. Its compact construction means it requires less floor space, providing a small footprint. It is also mobile, able to be relocated to other areas on the shop floor or even another facility. Installation and coating production startup is quick.

The Coating Machine comes with cables preinstalled in accessible cable trays and incorporates FST’s 50 series digital platform and Horizon software. It is also designed with safety features to protect personnel and equipment. Operators are 75% less exposed to toxic fumes, dust and noise. The Coating Machine is also customizable with a Go-No Go process control system, FST I Remote Assistance, and data logging and reporting.

RELATED CONTENT

-

Automated Measuring Systems for Coating, Electroplating

Photo Credit: Fischer Technology Inc.

-

Automated Wastewater Treatment, Evaporation System

Photo Credit: Kontek Kontek Process Water Management is a privately owned, ISO-9001 certified company with primary offices and manufacturing facilities located in Burlington, ON, Canada.

-

Combining AGVs, Software for Greater Paint Shop Efficiency

The EcoProFleet from Dürr is an automated guided vehicle that coordinates with the company's DXQ software to bring about maximized utilization.