Cetec ERP Release Includes Order Batching

The feature streamlines work order batch management and provides additional shopfloor control for effective production management in manufacturing.

Edited by Lori Beckman

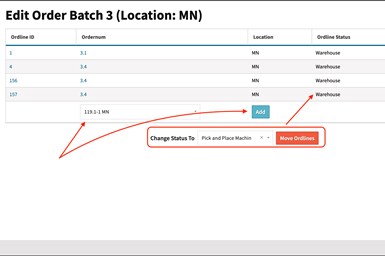

The image shows a batch of distinct work orders grouped together. This screen is where a production manager can search and add work orders and move them to the next step in production.

Photo Credit: Cetec ERP

Cetec ERP, a cloud-based ERP software provider, has released an updated software version that includes order batching. The feature enables users to group work orders together as a batch by keying in or scanning an order number and is included in all the company’s existing ERP systems.

On the new batch view screen, time can be logged to the batch, then split equally across all associated work orders within the batch. Additionally, the work order location enables users to update the production status of the batch, which will automatically update the individual work orders, keeping complete, real-time data on the production floor. Materials can subsequently be issued (or picked) to a batch in proportion to the quantity needed for that material for each batched work order, providing accurate inventory management, and maintaining critical lot traceability.

The image shows a batch of distinct work orders grouped together. This screen is where a production manager can search and add work orders and move them to the next step in production.

In discrete manufacturing, the order batching feature enables companies to schedule and group orders for production, speeding up production and data entry of time and order status, the company says. This keeps data entry at a minimum for shopfloor employees and production managers or supervisors attempting to schedule efficiently and reduce machine downtime for setup and programming.