Editorial, News, and Products

Selective Electroplating's Role in Remanufacturing

Selective plating offers a method of repairing and restoring surface properties of worn components back to OEM standards.

SIFCO New Plating Technologies

SIFCO New Plating Technologies

FABTECH 2021 to Bring the Industry Together

FABTECH returns to McCormick Place in Chicago, Ill., September 13-16.

40 Under 40: Class of 2021

Each year, PF editors comb through a long list of nominees with a wide range of skill sets to select the 40 Under 40 class. This year's finalists include engineers, operations managers, chemists, general managers, sales professionals and entrepreneurs working in the finishing industry.

Happy National Surface Finishing Day 2021

National Surface Finishing Day celebrates the contributions of the finishing industry to manufacturing and celebrates surface finishing professionals.

SIFCO ASC Earns ISO 14001:2015 Certification

SIFCO ASC has implemented environmentally minded improvements to its workflow and office that have earned it an ISO 14001:2015 certification.

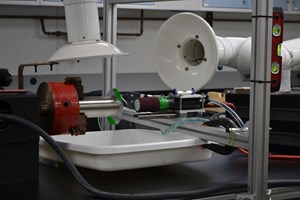

SIFCO ASC Reduced Selective Plating Costs with Automation

SIFCO ASC’s automated selective plating workstation not only improved the surface quality of finished products, it reduced process times by 90% and saved Powell Electrical Systems around $100,000 annually.

Brush Plating with Metal Matrix Composites

Hard chrome has been used in the plating industry for decades, but due to the environmental and health risks associated with chromium compounds, there’s a call for change. Josh Thomas, electrochemist at SIFCO ASC discusses brush plating and metal matrix composites (MMC), a new generation of electroplating solutions.

Polamer Precision Incorporates Selective Plating Into Production Line

Global aerospace manufacturing company Polamer Precision, has worked with SIFCO ASC to bring a selective plating process in-house for improved output, lead time and quality control.

A Conversation for International Women in Engineering Day

SIFCO ASC engineers Dr. Ani Zhecheva Brain and Danijela Milosevic-Popovich discuss the challenges of being a woman in a STEM related field, reflect on the achievements of women in engineering and talk about opportunities for women and girls interested in STEM.

Sifco ASC's Travel Kits Designed for Quick Repairs

Sifco ASC's brush plating Travel Kits are made in cadmium, zinc-nickel, and silver noncyanide.

Women in STEM: A Spotlight

Danijela Milosevic-Popovich is a Research and Development Manager at SIFCO Applied Surface Concepts.

Sifco ASC Travel Kits Offer Portable Touch-ups

Kits are designed for on-site operations where repair times are critical.

Automate Your Brush Plating Operation

Derek Kilgore from Sifco ASC says the brush plating operation can be mechanized, semi-automated or even fully automated.

Best Plating Practices for the Application of Brush Plated Zinc-Nickel

Brush plating is an industrial electroplating process designed for demanding OEM and repair applications, without the use of an immersion tank. This presentation demonstrates the best practices for brush plating zinc-nickel to meet the ASTM standards of hydrogen embrittlement and corrosion protection. From preparatory steps to the application of a trivalent chromium conversion coating, the proper plating techniques needed to meet the customers’ demanding requirements are discussed.

Sifco ASC Welcomes New Ownership

Quaker Houghton has acquired Norman Hay PLC, a private UK company that provides specialty chemicals, operating equipment and services to industrial end markets.

Sifco ASC Receives Presidential Award for Exports

Secretary Ross says that Sifco ASC had more than 50% increase in export sales over the past four years.

Power Pack Line Designed for Portability in Selective Plating

Lightweight design and enhanced functionality geared to improve quality, flexibility and safety in selective plating.

Sifco ASC Holding Free Plating, Anodizing Webinar April 24

Focus will be on manufacturing throughout the aerospace supply chain.

Sifco Plating Systems Integrates to Most Production Lines

Sifco’s automated plating systems can be integrated into any production line.

Manufacturer Seizes onto Selective Copper Plating

CW needed to selectively plate a thin layer of copper for anti-galling purposes onto the threads of newly manufactured stainless-steel components.

Sifco ASC Adds Corrosion Engineer to R&D Team

Sarah Mederios developed her industry experience during her time as an engineering co-op with the Lubrizol Corp.

Sifco ASC Modernizes R&D Lab

Originally built in 1992, this is the first major renovation to the site, designed to give research engineers a spacious, practical and durable facility in which to conduct R&D work for the company’s selective brush plating solutions.

Sifco ASC Staff Help at Local Food Bank

A total of 29 colleagues donated 116 volunteer hours to this worthy cause to help the Greater Cleveland Food Bank, which provides more than 50,000,000 meals each year.

Automated Selective Plating Takes Off With Safran Project

Sifco ASC has partnered with Safran on various surface finishing projects for more than 20 years, including recent work to increase wear resistance on an aircraft’s axles.

Study Reveals Finishing Industry Barriers to Phasing Out Cadmium

Sifco conducted the survey, which they say was done to gage the industry knowledge of about speculation that the U.S. aerospace industry will phase out cadmium by 2023.

Turbine Repairs Call for Selective Brush Plating Solution

IPS uses in situ repairs to minimize downtime and maintain revenue flows.

Surface Technology Plates Second Cycle of Brompton Bikes

The Nickel Edition, the most advanced finish used by Brompton to date, is electroless nickel plated by Surface Technology at its Leeds facility in England.

Plating Clinic: Adhesion of Brush Plated Deposits

Q. How well does a brush-plated deposit adhere to the base metal?

Sifco White Paper Talks Best Kept Aerospace Secret

The white paper makes the case for a wider adoption of selective plating, both for salvage and repair as well as many OEM applications.

Portable Plating Process Repair Gets Crane Mining Again

By repairing the pinion gear of a mining crane in-situ with a selective plating process, a crane was able to return to service with minimal downtime and extend the working life of the gear components.

Localizing a Surface Solution

The application potential and benefits of selective brush plating.

SIFCO ASC Flies High With Added Seal Of Approval From Nadcap

Company receives Nadcap AC7108 Rev F accreditation for chemical processing for the aerospace sector at its Cleveland and Connecticut facilities

SIFCO ASC Achieves OHSAS 18001 Certification

OHSAS 18001 standard is an internationally accepted method used to assess and audit occupational health and safety management systems.

Selective Brush Plating a Tin-Zinc Alloy for Sacrificial Corrosion Protection

A tin-zinc selective brush plated coating has been developed to provide sacrificial corrosion protection without the use of toxic chemicals.

Sifco ASC Launches New Brand Identity And Website

Company launches a new corporate identity and website showcasing the full range of its products and services for component enhancement, repair and refurbishment.

Sifco Applied Surface Concepts Group Acquired by Norman Hay Group

Sifco ASC brand is one of the largest manufacturer and supplier of process equipment and associated chemicals for selective electroplating and anodizing. It also has its own subcontract process operations across the U.S. and Europe.

SIFCO ASC Featured on FOX Business Network

“Manufacturing Marvels” segment on The Willis Report on FOX Business Network. The episode airs Friday, July 27 from 9:00-10:00pm EST.

Touching Up: Selective Brush Plating in the Field

Selective brush plating is much more than just a touch-up repair process. Hundreds of applications are using the selective brush plating process to provide surface enhancement coatings to aircraft OEM applications.

Brush Plating

The benefits of plating localized areas with a portable plating system.