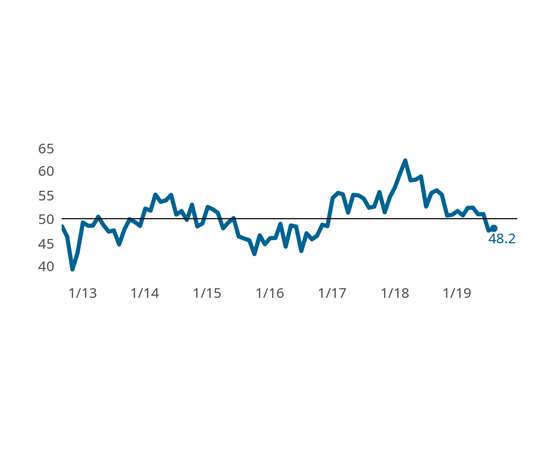

Finishing Index Makes Progress Back Toward ‘50’

August Finishing Index is 48.2, indicating that overall business conditions contracted for a second month, but at a slower rate than previously recorded.

#economics

The Finishing Index registered higher in August at 48.2, after previously posting a multiyear low. The latest Finishing Index reading indicates that overall business conditions contracted for a second month, but at a slower rate than previously recorded. Index readings above 50 indicate expanding activity, while values below 50 indicate contracting activity. The further away a reading is from 50 the greater the magnitude of change. For August, the Index was supported by expansionary activity in supplier deliveries and production. The Index — calculated as an average of its components — was pulled lower by contracting activity in exports and backlogs. Employment and new orders contracted slightly during the month, but overall raised the Finishing reading. Excluding supplier deliveries, all components registered higher absolute readings in August.

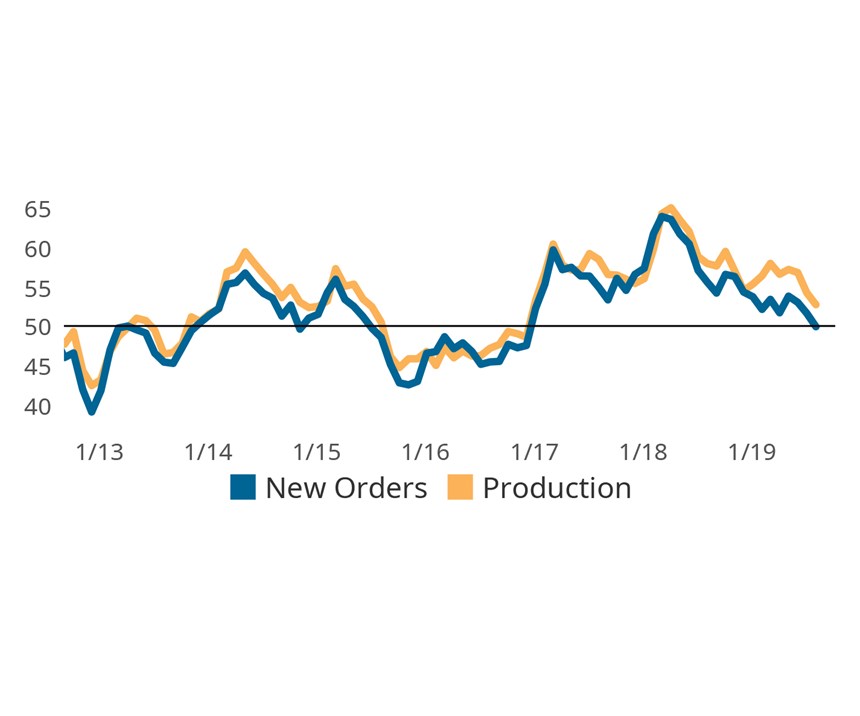

In the year-to-date 2019 period, production activity has registered higher levels of activity relative to new orders. One result of this is that backlog activity has contracted sharply during this time. These data suggest that finishers are sustaining production activity in the face of weakening new orders by drawing down backlogs. Prior to this, exports were the fastest contracting component of the Index going as far back as late 2017.

RELATED CONTENT

-

Aluminum Anodizing

Types of anodizing, processes, equipment selection and tank construction.

-

Overview: Aerospace Anodize Finishes

The following anodizing process overviews are provided as a means of introduction to aerospace anodizing

-

What is the Correct Anodizing Specification?

My company fabricates aluminum and steel pedestrian bridge railing among other bridge parts. We recently got an aluminum railing job that called for “Type I” anodizing per MIL-A-8625. There was no anodic coating thickness called out. We are not anodizers and we are at a loss as to how to write up a meaningful anodizing specification for this railing.

.jpg;width=70;height=70;mode=crop)