Plating Options for Hydrogen Technology

Holzapfel Group develops plating solutions for hydrogen production.

Share

Read Next

German coatings provider the Holzapfel Group (Sinn, Hessen, Germany) is developing plating for hydrogen production technologies, with a focus on renewable energy markets.

The company says that by developing the corresponding functional layers, surface technology can provide the parts and components used in hydrogen technology with new properties — such as adding protective functions that make them more durable, effective and efficient.

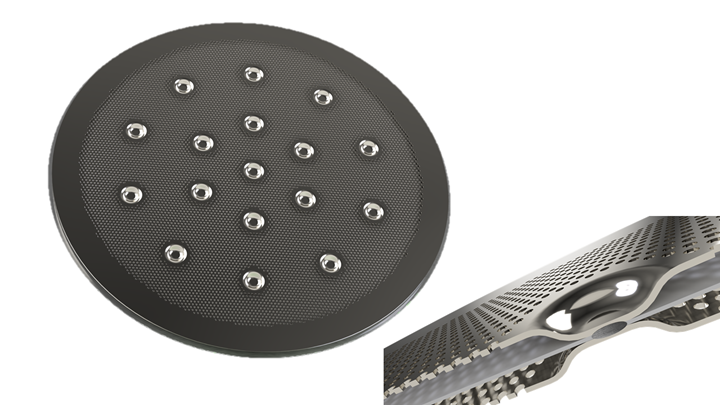

The Holzapfel Group can plate the components used in electrode packages, such as anodes, cathodes, separator plates and end plates, but also cell frames and water-bearing components, with a functional layer that protects them from corrosion. Components up to a size of 2300 x 2100 mm can be plated for use in alkaline water electrolysis. Other processes such as electroless nickel, nickel sulphamate, electroplated nickel, silver, tin, zinc-nickel and other coating combinations are also available.

The company says that first and foremost, it is necessary to plate the various components in order to ensure the durability and service life of the entire system. Applying a corrosion protection layer can make the parts considerably more resilient and a crucial reason is the improvement the plating brings in terms of efficiency. From a mechanical point of view, this treatment ensures the electrode packages deliver optimal performance. The Holzapfel Group claims that compared to nickel plating, its processes ensure significantly greater efficiency and thus a more economical mode of operation due to their lower energy consumption.

Related Content

-

Liquid Chrome Vs. Chromic Acid Flake

Contemplating how to continue offering chromic acid services in an increasingly stringent regulatory world? Liquid chrome products may be the solution you’re looking for.

-

Cleaning for Plating Success

A quick guide to surface preparation prior to electroplating.

-

Advantages to Pumped Eductor Agitation

Not all agitation methods are created equally. Pumped agitation with eductor nozzles can improve process tanks and quickly show a reduction in operating costs while keeping staff safe, following environmental legislation and preventing pollution.