Advantages to Pumped Eductor Agitation

Appears in Print as: 'Get Pumped About Eductor Agitation'

Not all agitation methods are created equally. Pumped agitation with eductor nozzles can improve process tanks and quickly show a reduction in operating costs while keeping staff safe, following environmental legislation and preventing pollution.

#sustainability

With an increased need to improve process efficiency while reducing costs and improving the working environment, pumped agitation with eductors has quickly become the preferred technology in the surface finishing industry. Every week, process tanks operating with air and mechanical systems are being replaced with this type of agitation on a variety of applications throughout the world. When properly designed, pumped agitation will optimize a process that results in a homogenous solution.

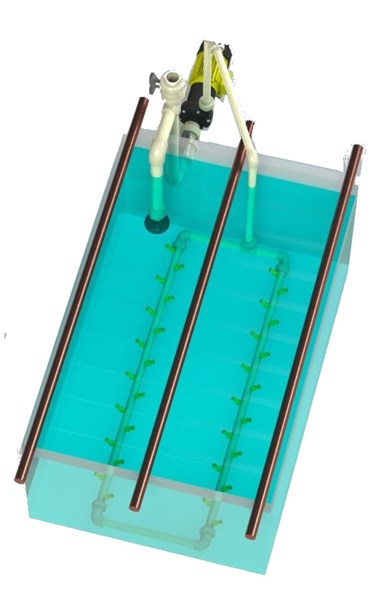

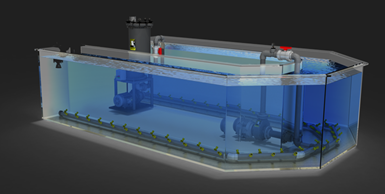

Pumped eductor agitation has many advantages that include lower heating costs, reduced emissions, even temperature, reduced brightener consumption and chemical evaporation, elimination of distorted air spargers, better filtration and plating on complex parts that may have bends or folds. The manifolds design by Serfilco (Northbrook, Illinois), for instance, can also help to eliminate the buildup sometimes experienced around heating elements or anode bags.

Featured Content

Eductor nozzles use the Venturi principle that amplifies and directs solution from the pump to the required area in the process tank. For each gallon of pressured liquid that enters the nozzle, five gallons recirculate at the output of the nozzle. The nozzle is converting a high pressure, high velocity, low volume flow into a low pressure, low velocity, high volume flow, creating a closed loop agitation, all while using a small pump and strategically positioned nozzles.

Common Methods of Agitation

Other common methods of agitation, such as air or mechanical, have more disadvantages than advantages. For instance, air agitation’s explosion of air

An alternative to pumped eductor agitation, air agitation, has more disadvantages than advantages. Air agitation’s explosion of air bubbles on the surface of process tanks produces foam and chemical fumes which create a potentially dangerous environment as well as an increase in rejects. As these air bubbles rise to the top of the process tank, latent heat is lost to the atmosphere, increasing the energy input required to sustain operating temperature. Photo Credits: Serfilco

bubbles on the surface of process tanks produces foam and chemical fumes which create a potentially dangerous environment as well as an increase in rejects. As these air bubbles rise to the top of the process tank, latent heat is lost to the atmosphere, increasing the energy input required to sustain operating temperature. The holes in the air sparger are small, making them prone to blockage, commonly producing a turbulent surface in only parts of the process tank, which is an indication that the agitation is not uniform throughout. Air oxidation also accelerates the breakdown of brighteners, causing consumption to increase drastically. Finally, compressors are inefficient and expensive to run, while air blowers are noisy and difficult to control.

Mechanical agitation, another common type of agitation, consists of lateral movements of a cathode bar throughout the length of a tank. Cathode rod movement is limited to a slow backward and forward movement through the length of the process tank, making the distance the bar moves become lost cathode space. The rod cannot have too much movement because a wave within the tank can form, which then can cause solution to splash out of the tank.

Designing the right system

Taking the time to understand an application’s needs in order to design a pumped eductor agitation system unique to the process tank is essential to maximize the system’s effectiveness to provide a homogenous tank. Most process tanks use vigorous turbulence to ensure constant movement within and throughout the tank. Electroless nickel, electroless copper and alkaline zinc should avoid direct impingement on the parts where general agitation is effective.

Solutions such as phosphating and cleaners benefit from agitation focused on the tank floor to prevent any sludge from settling and keeping those solids in suspension for removal by a separate filtration system. Filtering these types of solutions alone with no agitation would not produce the desired cleansing of the process tank.

Considering the tank configuration, including the dimensions, anode/cathode placement, heater locations and rack placement, along with the type of process, is the most effective way to calculate the size, number and position of the eductor nozzles. This then determines the size pump required to achieve the calculated flow required to successfully agitate the process tank. It is always recommended that a flow valve be installed between the pump and the eductor manifold so the agitation can be controlled easily. To avoid excessive

Taking into account the tank configuration, including the dimensions, anode/cathode placement, heater locations and rack placement, along with the type of process, is the most effective way to calculate the size, number and position of the eductor nozzles.

pressure drop, it is important to ensure pipework is at least the same size as the pump discharge.

Filtration and agitation

It is recommended that a separate pump from a filtration system be used. When sizing a pump for a calculated number of eductor nozzles, the tank turnovers should not be considered for filtration. Instead, consider the appropriate pump for the calculated number of eductors and separately calculate tank turnovers, depending on the process tank, to recommend a separate filtration system complete with its own housing, pump and media. When there is cartridge media that retains contaminant, there will be a drop in flow. When this occurs, the effectiveness of both the filtration and the agitation is severely compromised.

Best processes

Eductor-pumped agitation has been successfully introduced in several processes where it has exhibited performance improvements compared to other methods by reducing heating costs, saving brighteners and reducing rejects (especially with complex parts), reducing hydrogen pitting and, most importantly, providing a homogeneous solution.

Nickel and chrome, acid copper, electroless nickel and copper, phosphating, cleaning and rinses, anodizing, alkaline and acid zinc, cadmium, tin, cyanide copper; electroforming, gold, rhodium and silver are the processes that are most successful using eductor-pumped agitation.

A relatively small capital investment is required to install an eductor-pumped agitation system, and a payback can be seen in a short amount of time.

About the Author

Melissa Escobar

Melissa Escobar is the Business Development Manager for Latin America and a

technical applications specialist at Serfilco. Melissa has had the honor to work with global electroplaters and anodizers in North and South America, providing outstanding customer service and technical advice.

RELATED CONTENT

-

Cleaning Limescale from Galvanized Steel

How do you clean white lime scale and rust spots on galvanize?

-

Stripping of Plated Finishes

The processes, chemicals and equipment, plus control and troubleshooting.

-

Zinc Phosphate: Questions and Answers

Our experts share specific questions about zinc phosphate and pretreatment