Drag Finishing of Delicate Parts

For complex parts with high surface finish specs, production deburring and surface prep can be done using the drag finishing process whereby the parts to be deburred and finished are mechanically dragged through the media while attached to fixtures—thus preventing the parts from contacting one another.

Drag finishing is a specialized version of mass or vibratory finishing—different in that the parts to be deburred and finished are mechanically dragged through the media while attached to fixtures—thus preventing the parts from contacting one another.

Mechanical surface finishing, also known as mass finishing or vibratory finishing, is a technology that has been around for more than six decades. Its applications range from burr removal, putting a radius on sharp edges, and degreasing and de-rusting/de-scaling of metal parts, all the way to high-gloss polishing of metal components. Mechanical finishing is generally associated with vibratory tumblers, centrifugal barrels or centrifugal disk machines.

Featured Content

Usually, such finishing systems consist of a work bowl filled with a mix of grinding or polishing media and the parts that need to be finished. By way of vibration or centrifugal force, the mass of media and parts is put into motion. The constant rubbing of media on parts over a certain period of time—from a few minutes to several hours—produces the desired surface finish.

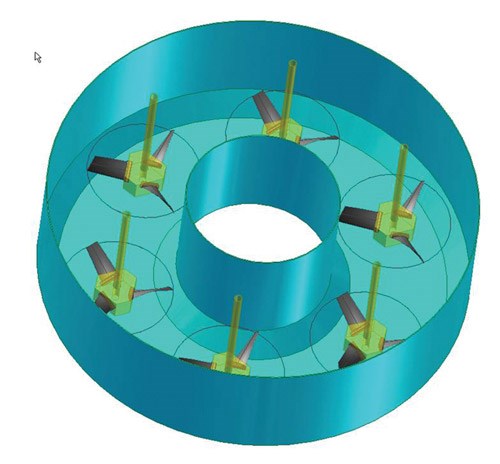

In recent years, drag finishing has become a popular alternative for surface finishing of high-value and somewhat delicate metal components. Like pushing a plow through the soil and, thus, polishing its blade, in drag finishing systems, parts mounted to a carousel equipped with multiple workstations are dragged through a circular work bowl filled with grinding or polishing media.

Pressure and Speed

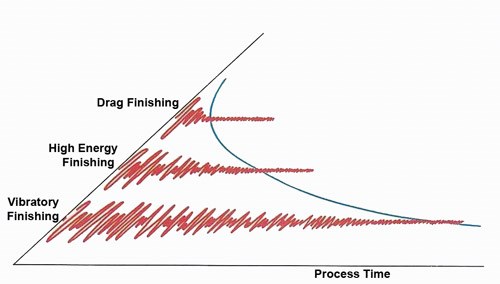

Mass finishing is all about pressure and speed. The higher the pressure exerted by the media on the parts, and the faster the media rubs on the parts, the faster the desired finishing results can be achieved. In this respect, drag finishing stands out over other finishing methods: Because of the high speed at which the parts are dragged through the media and the high pressure generated, drag finishing works 40 times faster than vibratory systems and about four to five times faster than high energy systems. High speed and pressure make drag finishing an optimum method, especially when it comes to parts made from hard-to-machine metals like high-alloy steel (stainless, titanium, Inconel, and so on), tool steel or parts with a high surface hardness.

No Part-on-Part Contact

The most outstanding characteristic of drag finishing is that parts are individually mounted onto workstations of the carousel. Depending on machine size, a carousel is usually equipped with four to 12 workstations, with each workstation loaded with one or multiple parts.

Compared with conventional mass finishing systems where the parts are free-floating in the media, in drag finishing systems, the parts—being individually attached to the workstations—never touch during the finishing process, thereby preventing part-on-part contact and any nicking or marring of the finish.

Individually mounting requires special part fixtures, which can sometimes pose an engineering challenge. But the payoff is worth the effort.

Aggressive Deburring to High-Gloss Polish

Applications for drag finishing range from aggressive deburring and edge breaking all the way to high gloss polish. A few examples of successful drag finishing applications include:

• Grinding and polishing of stainless steel boat propellers: These castings undergo a drag grinding process in one machine followed by a polishing step in a second drag finisher.

• Paint preparation of outboard marine drive components: These die castings require the removal of heat checks, breaking of sharp edges and a homogeneous surface finish prior to painting.

• Surface smoothing and polishing of turbine blades after machining and shot peening: This application reduces the surface roughness from Ra = 70 to Ra < 10 (1.8 micrometers to < 0.25 micrometers).

• Grinding and polishing of medical implants such as artificial knees, hip stems, ankles, and so on: After casting, these parts are machined and then undergo a multi-stage drag finishing process for aggressive surface grinding, surface smoothing and high-gloss polishing.

Consistent, Economical

Drag finishing is not an inexpensive surface finishing technology, but the technical and economic rewards can far outweigh the cost.

These systems frequently replace manual deburring/grinding operations. Manual deburring/grinding is highly labor intensive, and it is difficult to find operators willing to perform this physically demanding and extremely noisy and dirty work. Above all, the quality of manual grinding depends entirely on the people doing the work and their physical and mental condition. For this reason, manual deburring/grinding usually produces a significant amount of rework or even scrap.

On the other hand, once a drag finishing process is locked in, it consistently produces the same high finish quality day-in and day-out. With automation, the human factor can be totally neutralized and srap/rework can be reduced to practically zero from sometimes double digit percentages.

In mass finishing systems, regardless of part shape, the grinding or polishing media totally envelop parts to be finished, reaching all surface areas. Naturally, this also applies to drag finishing. Especially in the medical implant industry, drag finishing systems have increasingly displaced robotic grinding and buffing systems, which are limited when it comes to reaching certain surface areas of parts with a complex geometry.

Tailor-Made

Drag finishing systems are usually designed around the customer requirements, so a range of types and sizes of equipment is available. Of crucial importance are the size and quantity of parts that need to be finished. Generally, the rule-of-thumb “the bigger the part, the bigger the machine” must be applied. Of course, quantity also plays a big role. But just-in-time batch quantities may dictate small, multiple units instead of one large drag finisher.

At one extreme, there are “mini drag” systems on the market with as many as four workstations and a bowl diameter of 40 to 50 inches. At the other, “maxi drag” systems may have ten to 12 workstations and a bowl diameter of more than 180 inches.

Fixturing of parts to the workstations is of crucial importance, so they are always custom designed per application. Close communication between the customer and designer ensures that aspects such as degree of automation, wear protection, masking of certain areas, and so on are taken into consideration.

Whenever a manufacturer produces high value parts with a complex geometry, and these parts require a first-class surface finish (be it strictly functional or decorative), drag finishing is a surface finishing technology worth considering.

For information on Rosler Metal Finishing USA, LLC, please call 269-441-3000, or visit rosler.us

RELATED CONTENT

-

Polishing vs. Buffing: What's the Difference?

Is polishing the same as buffing? Mechanical finishing expert, Pat Wenino, explains the differences between the two processes.

-

Mastering Sanitary Stainless Steel Finishes

Here’s a primer on the types of finishes required for equipment used in sanitary applications.

-

High Fives for the Surface Finishing Industry

National Surface Finishing Day offered what seems to have been a missing component in our makeshift gatherings over the past year, which is a chance to celebrate together.