Finishing Solutions Beyond the Surface

Not only does Imagineering provide EN, passivation and phosphating, it helps engineer the coating you want and need on your part…

“Most companies do not start off as large, successful enterprises, and few are ever totally satisfied with where they are to date. And our firm is no different,” noted Jim Hammer, president and CEO of Imagineering, Inc., (South Bend, IN). Imagineering may seem like a small company to look at the building, but it is anything but small—particularly when it comes to its intellectual capital, business systems, strategic alignments and ideas about growth. “With global supply chains consolidating, some of our customers are delegating more responsibility and demanding more services from fewer vendors. As we continue to prove our expertise and demonstrate our quality, we will earn the opportunity to serve as a ‘preferred supplier,’ which hopefully results in an expanded business relationship. Our business strategy is to further penetrate the needs of our existing Fortune 1000 customers and those companies that service them.

“Today,” he continued, “opportunities are available to high achieving vendors because customers must comply with stricter operating policies, lower target costs, tighter deadlines and more complex service requirements. If we help optimize those constraints, we should see higher sale volumes and greater growth potential. We are always on-call for our customers.”

Featured Content

Many of the companies requesting assistance are larger aerospace, automotive and military related companies that have metallurgists and materials engineers on staff, but not coatings experts. They come to Imagineering for their finishing needs, because it offers more than a finish. “We have a unique ability to assist companies that do not have in-house finishing expertise,” stated Dan Englebert, vice president of technical services, for Imagineering.

The Imagineering staff focuses on providing excellent customer service in addition to unsurpassed finishing technical expertise. With TQM (Total Quality Management) as its guiding management philosophy, the company has developed a culture of employees that are empowered to serve the customer. It has made a major investment in training people and developing an information system to achieve quality and environmental certifications, including QS 9000, ISO 9002, ISO 14001 and NADCAP accreditation, which is probably the most stringent of all. NADCAP (National Aerospace and Defense Contractors Accreditation Program) represents major prime contractors, suppliers and government agencies in aerospace, defense and related industries. Through the program subcontractors and suppliers to these industries are accredited with meeting industry standards.

Imagineering has always offered more. Founder Dave Huber based his senior year metallurgy thesis at Notre Dame on imaginative engineering—finding innovative ways to do what is seemingly impossible to do in a cost effective manner. In 1959, when Mr. Huber first started the company, drum brakes were state-of-the-art. South Bend’s history is not only rich with football, but also heavy in the automotive brake business. At the time, manufacturers would grease the adjusters in the drum brake assembly. As the brakes would wear, brake dust, road salts and other debris would get into the grease and gum it up, forcing replacement and repairs. Mr. Huber and a team of scientists developed a dry film lubricant that replaced the need for oil and grease. Brake dust and road grime inhibited the proper functioning of the assembly and the dry film lubricated assembly eliminated the need for frequent, costly repairs. This coating application represented the primary revenue base for Imagineering’s business, and the company finished tens of millions of components during a 25-year period. As the drum brake market matured and disc brakes became the norm, this application was phased out of the business.

Non-Destructive Testing

Imagineering’s one coating operation, however, grew to include a number of high-end coatings for the medical, aerospace and nuclear industries, as well as non-destructive testing (NDT). Many of the military and aerospace parts Imagineering handles are critical hardware, where one failure is unacceptable. NDT provides a way to look at a part and inspect it for defects without damaging it. The liquid penetrant process, which Imagineering uses, can be used on metallic and non-metallic substrates.

The most important step in liquid penetrant NDT is surface preparation. The surface must be clean so that the penetrant can enter any flaws in the part. The penetrant is applied using a spray, brush or immersion process. After the appropriate dwell time, the penetrant is removed and a layer of developer is applied. By capillary action, the penetrant is drawn to the surface defect where it becomes visible under UV lighting, indicating flaws in the parts. If a part meets the inspection approval criteria, it then receives abrasive blasting, passivation and/or another coating.

The NDT complements the finishes offered at Imagineering. Its core coating application is electroless nickel (EN) plating. EN plating technology employed by Imagineering includes two high-phosphorus, three mid-phosphorus and one low-phosphorus electroless nickel chemistries, in addition to several alloyed coatings, such as EN co-deposited with Teflon®.

Electroless Nickel

One particular job entailed EN coating four titanium parts for the army. Recessed areas and intricate masking made the parts all the more difficult to EN plate. “The process required a lot of hand work. Titanium is tough to plate because it is inert,” noted Mr. Englebert. “We used mechanical and chemical technologies as well as some heat treatment to get the EN to adhere. We enjoy taking on these types of challenging projects. Actually, we have earned a reputation for being able to solve challenging finishing jobs.”

Because it accepts more challenging work, the company likes to be involved as early as possible in projects. “If we are involved early, we can help a company determine what finish is best for its part, the best way to apply the finish and determine how closely we can come to meeting the target price,” commented Mr. Englebert. “We have to understand what they want, however. There are many options as far as chemistry, corrosion resistance, wear and composite coatings.”

Phosphate

Phosphating is another large market for Imagineering. As with EN, there are a number of different types and methods of phosphate coatings within the zinc and manganese phosphate families: microcrystalline, standard and macrocrystalline. The phosphating process converts iron, steel, galvanized steel or aluminum surfaces using a dilute solution of phosphoric acid and other chemicals to an integral, mildly protective layer of insoluble crystalline phosphate. Precleaning, activating rinses, application, temperature, concentration and time control the coating weight, crystallization and penetration. The coatings range in thickness from less than 0.1 to 2 mils; however, coating weight is used as the basis for calculating the amount of the deposit. Imagineering achieves high precision regarding coating weights.

Even though all phosphating baths are acidic and attack the metal to some extent, hydrogen embrittlement rarely occurs because of oxidizers that react with the hydrogen as it forms, rendering it harmless. In some cases, zinc and manganese phosphate processes used with corrosion resistant oils can cause hydrogen embrittlement because they may contain a minute amount of oxidizers. A dwell time between use or mild heating may relieve this embrittlement.

Zinc phosphates have a range of weights and crystal characteristics, including heavy films with macrocrystals and very thin films with microcrystalline deposits. These deposits can serve as a base for paint, an aid to forming, and to increase wear and corrosion resistance. “Zinc is a great pretreatment for coatings such as dry film lubricants,” explained Mr. Englebert. “Phosphates are great stand-alone coatings, but you can get multiples of performance when you add a dry-film lubricant. If you apply a zinc phosphate and supplement it with a Teflon-based coating, which will absorb into the zinc phosphate, you will have a coating that continually refreshes itself and performs at a high level. Some of these types of coatings are used in the space shuttle and satellites. Imagineering’s phosphate processes meets most major specifications, including MIL-DTL-16232 and Federal Specification TT-D-490. We also provide complete testing, thermal processing and supplemental treatments for phosphate coatings.”

Manganese phosphates also “drink in” oils and lubricants. These coatings are most often applied to internal engine parts to protect against galling. The coatings are applied during a 5-30 min immersion process. Coating weights range from 5.4-32.3 g/m2. Bath temperatures range from 190-200F. The manganese phosphate coatings applied are usually tight and microcrystalline because of their use in internal parts.

Passivation

Passivation is a niche market Imagineering has carved out for itself. “It can be seen as a black art,” said Mr. Englebert, “because there really is not much information on it. All the aerospace and medical companies specify it, yet there really is not a single authoritative source for information on passivation; and there is an incredible amount of misinformation used in the field. From an application standpoint, it is as much an art as it is a science.”

ASTM A380 states that passivation is removing exogenous iron or iron compounds from the surface of stainless steel by chemical dissolution, usually a treatment with acid that will remove the surface contamination but not significantly affect the stainless steel.

The process basically removes free iron left on the metal surface from machining and fabricating. The free iron (or other contaminants) provide potential corrosion sights, and, therefore, need to be removed. Passivation also aids the formation of a thin, transparent oxide film that protects the stainless steel from corrosion.

Passivation starts with a cleaning cycle (vapor degreasing, solvent cleaning, alkaline soak) designed to remove oils, greases, forming compounds, lubricants, coolants, cutting fluids and other organic and metallic residues left from fabrication and machining. After cleaning, parts are passivated, most often in a nitric acid solution.

Major variables that must be controlled during passivation include: time, temperature and concentration. Typical immersion times are 20 min to 2 hr, and temperatures range from room temperature to 160F. Nitric acid concentration in the 20-50% by volume range is generally specified. Many specifications that Imagineering works with include the use of sodium dichromate in the solution or as part of the post passivation rinse aid to help in the formation of a chromic oxide film.

Careful bath control is crucial for success. This goes not only for passivation but also for every bath in the facility. Two years from today, engineers can go into records and find out exactly what the temperature, concentration and immersion times were for the parts on a particular bath at 2:00 p.m. on May 30th.

The type of stainless steel (alloy) also determines the most effective type of passivation process. If the wrong bath is used on a particular type of steel, you can end up with pitting, etching and/or total dissolution of the component. These are examples of extreme cases.

In addition to ASTM A-380 and ASTM A-967 specifications for passivation, there are tests Imagineering performs to verify the process. One common test is the copper sulfate test during which parts are immersed in copper sulfate solution for 6 min, rinsed and examined. Any pinkish color indicates free iron, and the test is considered unacceptable. Other tests include a 2-hr salt spray or 24-hr high humidity test. Test methods should be chosen based on alloy type and end-use environment.

According to Mr. Englebert, “The most overlooked variable in the entire passivation equation is the negative impact of poor machining and heat treating practices. Often, cross contamination introduced during manufacturing and/or thermal processes leads to unacceptable test results.” He provides a list of suggestions to increase chances of successful passivation and test results:

- Never use grinding wheels, sanding materials or wire brushes made of iron, iron oxide, steel, zinc or other material that can contaminate the stainless steel surface.

- Carbide or other non-metallic tooling is recommended.

- Grinding wheels, sanding wheels and wire brushes that have been previously used on other metals should not be used on stainless steel.

- Use only clean, unused abrasives such as glass bead or iron-free silica or alumina sand for abrasive blast. Do not use steel shot, grit or abrasives that have been used to blast other materials.

- Thorough cleaning prior to any thermal processing is critical. Stress relieving, annealing, drawing or other hot-forming processes can actually draw surface contaminants deeper into the substrate, making them almost impossible to remove during passivation.

- Take care during thermal processes to avoid oxide formation. Passivation will not remove discoloration and will not penetrate heavy oxide layers.

“Passivation enhances the corrosion resistance of stainless steels,” explained Mr. Englebert, “but to realize the maximum performance from the high tech alloys, everyone involved with the manufacturing must understand their responsibility in maintaining the integrity of the material throughout the process.”

Because Imagineering does understand this, it has earned a reputation as more than a metal finishing company. Many customers look to Imagineering simply for advice, because it has access to the research and development efforts of global chemical suppliers and does a substantial amount of prototyping. “Once we arrive at a process that appears to work, we fine tune it. This helps us lead our customers down the right road, guiding them through an entire selection process,” commented Mr. Englebert. “Even if we don’t offer the process they are looking for, we can often recommend a company that does.”

This will happen less often in the future after the company moves to its new 67,000-sq-ft facility. Increasing its size will enable it to add more finishing processes. Many of its customers are asking for more finishes than those already offered, the most popular request being anodizing. “Many captive shops are trying to ease out of the plating business. They realize that their core talents are as designers, assemblers and not metal finishers,” explained Mr. Englebert. “Even machining and subprocessing is shipped out. This provides growth potential for companies such as Imagineering.” Imagineering may be a small company in a small town, but it is poised for even bigger and better things as it leverages its imagination and knowledge.

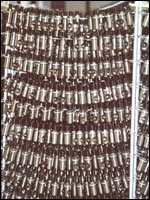

Brake parts are cleaned and phosphated in racks specially designed by Imagineering, which worked with a major OEM automotive supplier in developing the specialized process.

Imagineering uses innovative design of fixturing such as those seen with these brake parts racked for EN plating. It also employs creative cost containment ideas, such as the outsourcing of racking, sorting and packaging processes.

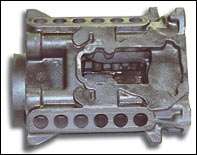

Intake manifold for a heavy equipment manufacturer is an example of a zinc phosphated and oiled part. One can see the recesses that need to be penetrated as well areas that would require masking.

RELATED CONTENT

-

Blackening of Ferrous Metals

The reasons for installing an in-house cold blackening system are many and varied.

-

Cleaning, Pretreatment to Meet Medical Specs ISO 13485 or FDA 21 CFR820

Maximilian Kessler from SurTec explains new practices for industrial parts cleaning, metal pretreatment and decorative electroplating in the medical device industry.

-

Gold and Silver Plating Basics

An overview of precious metal electroplating processes.