Game Changing with Precision Ultrasonic Cleaning

Today’s high-tech automated systems meet exacting standards.

It’s been 20 years since a parts cleaning revolution launched in response to the implementation of the Montreal Protocol. Today, the stakes are much higher than they were in 1994. Now a proven, repeatable—and often validated—cleaning protocol is a selling point to customers and a requirement in industries where compliance is mandated, such as in the medical and aerospace industries.

Precision cleaning is cleaning taken up a few notches to meet these increasingly rigorous standards. Systems usually consist of a series of specially equipped process tanks or stations that perform cleaning, rinsing and drying in sequential order. Sometimes additional process steps are included, such as nitric or citric passivation to remove free iron from part surfaces.

Featured Content

To ensure conformance and repeatability, precision cleaning systems are typically automated, with processes advanced through each step in the program selected for that load. Most systems come with multiple automated programs. For versatility, it is possible to vary the stations that a particular program includes, as well as station dwell times. Programs can be modified on the shop floor using password-protected screens. For repeatability, automation ensures that once set up, the program repeats the process within the allowable margins every time, and for conformance, critical process data can be captured and stored electronically or printed out to meet documentation requirements.

Precision Cleaning Action

Cleaning starts with tanks, and there may be one or more cleaning tanks or stations in a precision cleaning line. These may be equipped identically, or they may differ depending on the variety of parts being processed, contaminant loading, and the types of cleaning chemistries required. For example, a cleaning line that is also performing nitric or citric passivation will have at least two different chemistries running in independent tanks on the line.

Precision cleaning stations typically feature heat to optimize chemistry performance and cleaning effectiveness, a filtration loop to remove particulates and extend bath life, and a surface sparge to skim floating soils to a separate weir prior to the removal of cleaned parts. Another available feature is automatic chemistry control, which might be handled in several different ways depending on the chemistry. Many cleaning chemistries can be monitored via conductivity and replenished by automatic feed as needed to continuously operate within the acceptable and/or validated conductivity range.

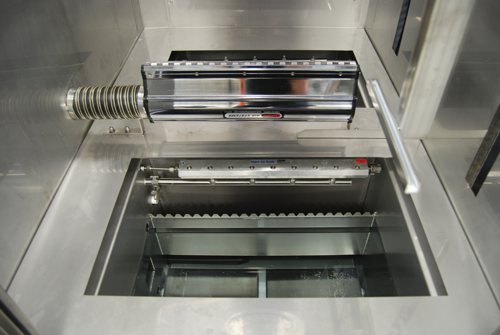

Ultrasonics are often specified for a precision cleaning process to both expedite and enhance parts cleaning action. Ultrasonic energy introduced into a tank creates microscopic bubbles that implode, breaking contaminants free in the process. This is called cavitation, and it can occur wherever the solution can go in the tank, including into complex part geometries.

Ultrasonics are available in different frequencies appropriate to the substrates and part geometries being cleaned. The lower the frequency, the larger the bubbles produced by the sound waves and the more aggressive the cleaning action. A frequency of 25 kHz is more aggressive than 40 kHz, with 40 being the most commonly applied frequency. Ultrasonics are also available in higher frequencies, as well as multiple frequencies, which may be preferable for delicate parts and smaller apertures.

Precision cleaning tanks are often equipped with additional types of mechanical actions to further enhance performance, and these, plus custom fixturing of parts to optimize exposure, have been game changers as the parts cleaning world has evolved. These additional mechanical actions include vertical agitation, spray, spray under immersion, and rotation. The recommended combination of methods depends on part geometry, substrate, type of contaminant and cleaning chemistry.

In an automated precision cleaning line, all of these features are controlled by programmable automation. Readings for critical process parameters such as time, temperature and chemistry concentration register in real time on the human/machine interface (HMI), which is typically a color touch screen. Conditions outside of the allowable range can be set to alarm and register on the HMI, or to be captured and stored for documentation purposes.

Thorough Rinsing and Drying

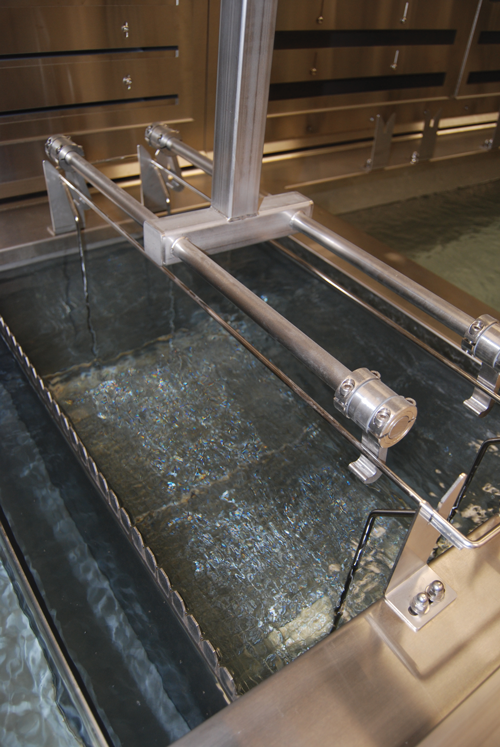

Cleaning is followed by thorough rinsing. On a precision cleaning line, this typically means a series of two or more rinses after each chemistry station on the line. These may counter-flow, which means the freshwater feed enters the second rinse which backflows to feed the first. The same water is used twice to reduce consumption, while maximizing rinse performance. When spot-free rinsing is required, either deionized or reverse-osmosis water is the recommended feed on the line.

Precision rinse tanks are often heated and may be filtered to a process-appropriate micron level. Some rinse tanks may be equipped with ultrasonics, agitation or other mechanical actions, depending on part complexity. When cleaning specifications are rigorous or throughput is high, a fresh feed spray on exit from the final rinse can also be beneficial.

Rinses may continuously flow, or flow in combination with rinse quality control, which measures allowable levels of conductivity or resistivity in the rinse water and calls for a fresh feed as needed. Critical parameters for rinsing, including conductivity/resistivity levels and/or flow, can also be continuously monitored by system automation, alarmed if out of specification, and recorded for conformance verification.

Once cleaned and rinsed, parts are typically dried in a recirculating hot-air dryer. In higher-throughput operations or where part complexity requires, a preliminary air blow-off or a subsequent second dryer may be added to improve productivity. Another variation is a drying tunnel. When cleaning success is measured by particle counts, the dryer may be equipped with a HEPA filter to remove particulate.

Specifying the System

When determining a new cleaning process or when implementing an existing cleaning specification in new equipment, the configuration and size of the system depends on several key items. The tank or station work area is determined by the largest possible batch size, and the number of cleaning stations depends on the level of contaminant loading, the variety of substrates to be processed, the process goals (clean or clean and passivate, for example) and the throughput requirements. The number of rinse stations depends on the number of cleaning stations, while the number of drying stations depends on throughput goals.

Test cleaning of parts is strongly recommended to verify process and performance when evaluating new equipment. Be sure that the proposed system has enough capability and versatility to successfully and repeatedly clean production-size loads.

If you do not have an established cleanliness standard, work with your vendor to capture the important details that can indicate success: visual inspection with or without magnification, water break tests, particle inspection, and/or success of a subsequent process such as coating or welding can be good measures. When passivating is included in the line, the ASTM A967 specification provides testing protocols.

The purpose of a precision cleaning system is to repeatedly produce clean, dry parts per specification while an operator is free to perform other tasks. This can be a game changer in the increasingly-stringent, and competitive world of cleaning success.

Cheryl Larkin is northeast regional sales manager for Miraclean. For more information, visit miraclean.com.

RELATED CONTENT

-

The Hull Cell: Key to Better Electroplating - Part I

How to use it for planning, preventive maintenance and troubleshooting.

-

Alkaline Cleaning Guide

Gregg Sanko, Senior Chemist, Oakite Products, Inc. provides an overview of the alkaline cleaning process.

-

Stripping of Plated Finishes

The processes, chemicals and equipment, plus control and troubleshooting.