Holistic Approach to Final E-Coat Rinse Operations

New final rinse technology optimizes ecoat process, reduces cost and improves sustainability.

#sustainability

In today’s highly competitive marketplace, owners and operators of electrocoating (e-coat) operations are seeking innovative ways to optimize their process operations, reduce costs and improve their environmental footprint, while also meeting or exceeding stringent quality requirements. Recently, a growing number of e-coaters are turning to a new final rinse (FR) technology to successfully address these issues. Understanding the benefits of this novel technology and approach to final rinse water systems management first requires a high-level review of the e-coating process.

E-Coating Process

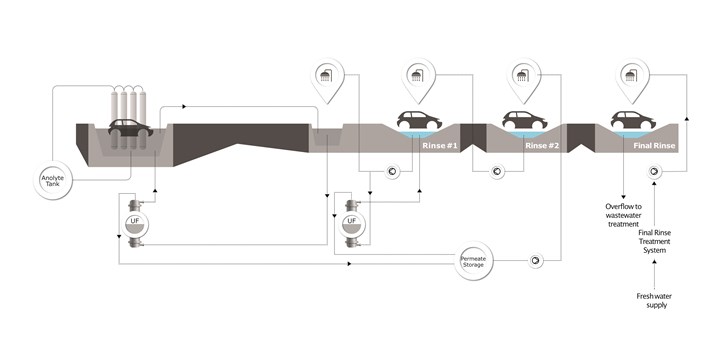

E-coating is widely used to adhere paint to metal surfaces using electrical charges. A metal part is immersed in a water bath in an anolyte solution (Figure 1) containing suspended electrically-charged paint particles, which are then transferred to the metal part thanks to an electric current running through the solution. The process, which can be adjusted by increasing or decreasing the voltage, continues until the required amount of paint is coated on the part.

Featured Content

Figure 1: Before Solecta FR Installation

Photo Credit: All images courtesy of Solecta

The finely-tuned solution in the anolyte tank contains specific amounts of paint pigment, binders and key additives that are necessary to avoid excessive buildup of pigment on the metal part. Maintaining the ratios of these components is critical to anolyte bath stability and the success of the process.

After completion of the anolyte step, the coated part typically goes through a series of rinse steps, where the part is rinsed with water to remove any residual and valuable paint particles, which are recovered using an ultrafiltration (UF) process. The purified water can then be recycled for use in rinse steps or the anolyte tank.

Final Rinse Stage is Complicated and Costly

The separate and final rinse stage of the e-coating process adds a significant degree of complexity and cost. It typically requires fresh water processed by deionization (DI) or reverse osmosis (RO) or fresh water from a city or municipal water source. This is required because contaminants in the water, such as bacteria, solids or other impurities, can cause cratering, roughness or streaking on the metal part that will persist throughout the drying process. When this occurs, the part must be scrapped or reworked.

Further complicating matters, final rinse water is typically not recycled, because its chemical composition differs significantly from the other recycle streams and will upset the tender balance of the paint bath. This clearly is problematic from both cost and sustainability points of view.

In addition, the final rinse stage eliminates the opportunity for a closed-loop system. Instead, separate water lines and separate water treatment operations must be maintained. Lastly, there is the need to purchase costly purified water that cannot be recycled. In sum, the final rinse stage of the e-coating process is both very expensive and a headache for e-coating process managers.

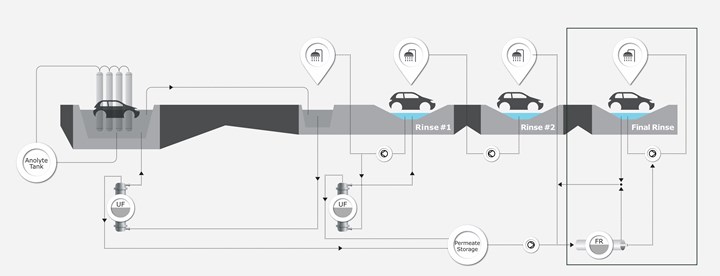

FR Technology Optimizes E-Coat Process, Reduces Cost and Improves Sustainability

Recently, e-coat operators have been working with Solecta (Oceanside, Calif.) to employ a more holistic approach that looks at e-coating in its entirety rather than as a two-step process. By understanding the nuances of the water balance, including both flow and chemistry, coupled with application expertise of the overall e-coat process, Solecta was able to develop a new process technology that eliminates the need for a final rinse stream and allows for water reuse without compromising final product quality. The new FR technology is inserted after the permeate storage tank (Figure 2).

Figure 2: After Solecta FR Installation

Delivering Measurable Results

The benefits of Solecta’s FR technology were evidenced by the results of a recently-completed project for a large automotive client. The client challenged Solecta to find a way to reduce the consumption of fresh water in the final rinse stage of the e-coating process; reduce wastewater treatment costs without jeopardizing final finish quality; and reduce paint costs by maximizing recovery of valuable paint solids.

Understanding the complex interconnections and variations in chemical compositions among the anolyte, the rinse and the final rinse baths, coupled with a detailed audit of the system, enabled Solecta to recommend that its client incorporate its FR technology in the e-coat process. This would address the client’s three challenges. First, it would allow water from the closed-loop rinse system to be used in the final rinse step, eliminating the need for fresh water. Second, the Solecta technology would enable the final rinse water to be reused in the previous rinse step, extending the closed-loop water system. Third, the client would be able to recover the valuable paint particles from the final rinse. Detailed analysis ensured that there would be no detrimental impact on the composition of the anolyte bath or its stability and no negative impact on the final e-coat product quality.

Holistic Approach Pays Dividends

In quantitative terms, the client was able to eliminate the consumption of nine million gallons of clean water and reduce paint and effluent costs. This resulted in savings for the client of $275,000.

Operational excellence is critical to winning in today’s highly competitive finishing marketplace. Looking at operations holistically presents a clear opportunity for e-coaters to reduce cost, conserve water and separate themselves from the competition.

About the Author

Ben Weaver

Ben is a senior sales engineer with Solecta, which employs advanced membrane technologies to provide highly selective, energy efficient separation solutions to the paint industry and other industrial sectors. He can be reached at ben.weaver@solectamembranes.com

RELATED CONTENT

-

Mechanical Vapor Recompression Evaporation

MVRE is underutilized in the treatment of industrial wastewaters that are typical of metal fabricating and finishing industries. Increasing energy costs, rapidly decreasing freshwater resources, and growing sensitivity towards the environmental impact of industrial management practices are the driving forces in the development of more sustainable technology.

-

Coating Plastic Parts More Efficiently

Quality, costs and sustainability in focus with liquid coatings.

-

Vacuum Deposition and Coating Options

This overview takes a look at vacuum deposition technologies as processes that may be used to create coatings that can be substituted for or enhances the properties of electroplated coatings. Initially, this work discusses trends in metal finishing and environmental regulation.