Zirconium Pretreatment Enables Broadcasting Solutions Manufacturer

A search for waste reduction and continuous improvement sparks an environmentally friendly collaboration for communications solutions.

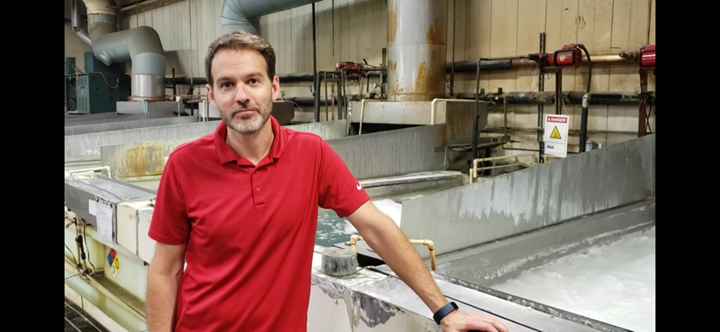

Ben Robinson, production manager for broadcasting solutions provider GatesAir, is always looking for continuous improvement opportunities.

Photo Credit: Gates Air

GatesAir, manufacturer of over-the-air solutions for TV, radio, and other broadcast transmission, prides itself on its vertical integration strategy concentrated in a 40-acre manufacturing facility in Quincy, Illinois. Founded in 1922, GatesAir is celebrating 100 years in business with an eye to the future of communications. The company’s PowerSmart high-efficiency TV and radio transmitter infrastructure was introduced in 2009 and is still the gold-standard for energy use today.

As a leader in the market, GatesAir continues to innovate, while seeking ways to reduce its carbon footprint and overall energy consumption. Ben Robinson joined GatesAir 22 years ago as an engineering intern and has been Production Manager overseeing all the finishing lines for the last 12 years. He is an expert in paint and pretreatment, but he is always looking for opportunities for continuous improvement.

Featured Content

GatesAir had already been using a zirconium pretreatment in its aluminum line but keeping the chemistry within operating parameters could be cumbersome and the aggressive etch cleaner process generated a lot of sludge that GatesAir had to collect and dispose of as HAZMAT waste.

Seeking a solution, Robinson found a like-minded partner in Don Ashcraft of Circle-Prosco Inc. (CPI, Bloomington, Indiana), who has more than 30 years experience in pretreatment, paint sales and technical service. Founded over 50 years ago, Circle-Prosco is a leading manufacturer of pretreatment chemistry with a focus on developing and implementing a process that consistently meets the required specifications not only in the lab, but on the paint line. The company’s fourth-generation zirconium pretreatments deliver superior adhesion performance and corrosion protection, but without the HAZMAT waste.

Both Robinson and Ashcraft found that GatesAir and CPI share a guiding philosophy that environmental benefit and economic benefit must go hand-in-hand. Both businesses have focused their research and development projects on products and processes that lower overall cost of use by reducing product footprint and energy consumption. The pair thought there might be some room for improvement in the pretreatment line, so they worked together to develop a test plan.

Alcoat is a phosphate- and heavy metal-free pretreatment that operates in as few as four stages. Photo Credit: Circle-Prosco

CPI’s Alcoat is a totally phosphate- and heavy metal-free pretreatment system that operates in as few as four stages and can be run at ambient temperatures. The first thing Robinson and Ashcraft investigated was whether the Alcoat pretreatment would improve GatesAir’s performance relative to the company’s specifications. After 164 hours in the salt spray chamber, the parts passed with flying colors.

Robinson needed to be confident that a CPI solution would make it easier for GatesAir to comply with wastewater permit requirements. The CPI Solution Squad confirmed that the Alcoat cleaners and pretreatments didn’t contain any ingredients that were restricted on the GatesAir wastewater treatment permit. This has allowed GatesAir to greatly reduce its HAZMAT sludge cleanout and disposal processes.

Finally, Robinson wanted to be sure that the transition to Alcoat would also be better for GatesAir’s team of operators. Once again, the CPI Solution Squad stepped in to help with training and an operating manual. Robinson and Ashcraft were proud to implement a solution with less aggressive pH levels to improve operator safety. Additionally, the charging chemistry has only four products for the entire line, down from eight in the old system, reducing the burden of training and day-to-day line maintenance.

Robinson and Ashcraft worked together to develop a transition plan to drop their old chemistry tanks, clean them out, and get the new chemistry loaded. Of course, implementation is where the rubber meets the road and where GatesAir and Circle-Prosco, Inc. really cemented their collaboration.

Sludge is cleared and GatesAir’s tanks are prepared for CPI’s cleaner and Alcoat.

Photo Credit: Circle-Prosco

Clement Anyadiegwu, a researcher in the CPI Solution Squad, donned his HAZMAT suit and got to work in the tank cleaning out the sludge and preparing the tanks for CPI’s cleaner and Alcoat. After a busy day, the team was ready to charge the tanks.

When Robinson started up the line with the new chemistry, he discovered one more bump in the road. Most of the metal that goes through the pretreatment line at GatesAir is Aluminum sheet stock, which was what the team planned for. However, about a quarter of the total volume of square footage is made up of milled parts which use a heavy cutting fluid. These parts weren’t getting clean enough to meet the GatesAir specs for performance on the line. The CPI Solution Squad jumped into action by taking a sample of the fluid and cleaner bath back to the lab to try to develop an alternative product that would take care of this curveball. Four days later, five chemists headed back to Quincy to try out their new custom cleaner.

That modified product did the trick and for the last year, GatesAir has been using Circle-Prosco’s Alcoat pretreatment products and cleaners on its Aluminum transmitter cases. According to Robinson, the biggest change he’s seen is “the ease of use for the total line, which translates to happier operators, easier preventive maintenance, lower costs, and less environmental impact.” Circle-Prosco’s Solution Squad retested corrosion resistance on the first day of line implementation to confirm that the lab results could be replicated in the production environment. Robinson was pleased, stating “It handily passed our requirements. In fact, every Alcoat test we have performed since implementation has handily passed. This chemistry is robust and has plenty of headroom for us to achieve our required performance results. In my world, this is a big deal.”

As for what’s next, Robinson would like to take his Iron Phosphate steel process away from phosphates, so CPI and Gates are working together to develop a customized solution for GatesAir’s steel processes.

While GatesAir and Circle-Prosco, Inc. are in two different industries with different processes and requirements, over each of their long histories, the two companies have developed a similar approach to manufacturing. They share a belief that the best product is the one that works best for their customers, that caring for the environment is good for the bottom line, and that a continuous improvement mindset is the key to longevity.

RELATED CONTENT

-

Conversion Coatings: Phosphate vs. Zirconium

Both phosphate-based and zirconium coatings have their advantages, but zirconium is fast becoming the pretreatment of choice.

-

Alkaline Cleaning Guide

Gregg Sanko, Senior Chemist, Oakite Products, Inc. provides an overview of the alkaline cleaning process.

-

Powder Coat MDF for an Enviable Finished Product

Cabinet maker says powder coating on wood offers more benefits.