Can-Am Engineered Products Inc.

30850 Industrial Rd.

Livonia, MI 48150 US

canamengineered.com

800-229-7551 | 734-427-2020 mbunnell@canamengineered.com

AS SEEN IN PRODUCTS FINISHING

Do you have a new product or news release that should be included here for Can-Am Engineered Products Inc.? We'd love to include it! Send your content to our editorial team.

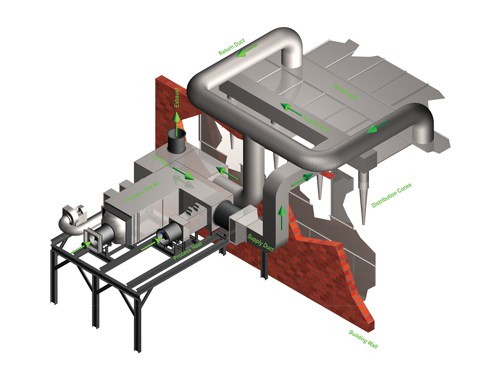

A “Bizarre” Approach: Using Moisture to Cure CARC Coatings

When veteran inventors Mike Bunnell and Daryl Bruischat put their minds together to build a better mousetrap for the drying and curing of waterborne CARC paints, they both hoped to come up with a system that might change the industry somewhat.

Product categories offered by Can-Am Engineered Products Inc.:

-

Cleaning & Pretreatment

-

Air Blow-Off Devices, Air Knives -

Controls, Fluid Pressure

-

-

Electrocoating

-

Ovens, High-Velocity

-

-

Painting

-

Air Make-Up Systems

-

-

Painting

-

Controls, Fluid Pressure -

Ovens, High-Velocity -

Painting Equipment

-

-

Powder Coating

-

Air Make-Up Systems

-

-

Powder Coating

-

Ovens, High-Velocity -

Painting Equipment, High-Volume/Low-Pressure Air Atomize

-

Is this Your Listing?

Connect with us to keep your company's information up to date.