Have a Blast Cleaning Parts

The concept of the wet blasting process in parts cleaning and surface finishing is straightforward enough: combine abrasive media with water to form a special slurry, then add regulated compressed air to control the pressure as it is discharged over a surface.

VDA 19 and its Impact on European Manufacturing and Cleaning

The German Association of the Automotive Industry’s VDA Volume 19 is the first comprehensive standardization document for characterizing the cleanliness of products within the automotive industry’s quality chain.

#automotive

Parts Cleaning Goes Under the Microscope

Increase productivity through automated cleanliness control of manufactured parts.

Ground Zero for Industrial Parts Cleaning Discharge

Proceco helps the R.H. Sheppard Co. attain zero waste after parts cleaning.

Q&A: Removing Buffing Compound

Readers says they hand-wipe clean using solvent then electroclean, but what is the best way to remove the buffing compound?

Cleaning Q&A: In-Line Cleaning Machine

A reader tells Parts Cleaning expert David Peterson that he is looking for in-line parts washing to put at his stamping press.

Cleaning Prior to PVD/CVD Coating

Determining the cleanliness and chemical de-coating of PVD/CVD layers.

#vacuum-vapor

Rinsing Difficulties

How helpful would it be to add a rinse aid to our post-process rinses in chromate conversion, and iron and zinc phosphate processes?

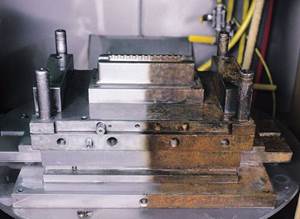

Drawn to Closed-Loop Cleaning

For Gem Manufacturing of Waterbury, Conn., meeting customer quality standards is critical to the success of the business. Part of that means removing the synthetic and water-soluble drawing lubricants used in Gem’s transfer and progressive presses, as well as any other contaminants that could have a detrimental impact on performance.

Mechanical Vapor Recompression Evaporation

MVRE is underutilized in the treatment of industrial wastewaters that are typical of metal fabricating and finishing industries. Increasing energy costs, rapidly decreasing freshwater resources, and growing sensitivity towards the environmental impact of industrial management practices are the driving forces in the development of more sustainable technology.

#sustainability #vacuum-vapor #energy

.jpg;maxWidth=300;quality=70)

.jpg;maxWidth=300;quality=70)