Differences in Masking and Plug Materials

Q. Can you explain the differences between masking caps and plugs?

#masking #basics

Hosco Wins Automation Alley Award

Award recognizes one advanced manufacturing or technology company in our region that has successfully launched its products, services or technologies abroad.

#Industry 4.0 #masking #curing

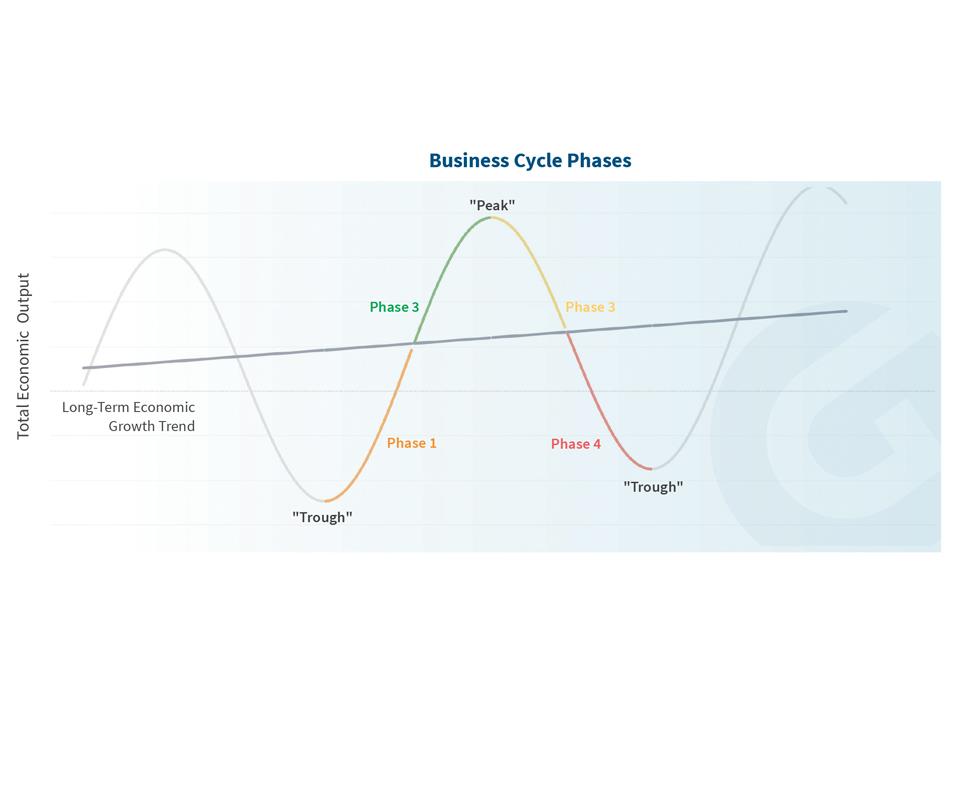

2017 Finishing Industry Economic Forecast

What the team at Gardner Business Intelligence sees ahead for the industrial finishing industry in 2017.

#Top Shops #finishinghalloffame #vacuum-vapor

Supplier Happiness Equals Sales Success

Working Relations Index measures partnerships between suppliers and OEMs.

PPG Coatings Selected by Airbus for A350-1000 Launch Aircraft

A PPG low-density fuel tank and fuselage sealant provides the three flight-test aircrafts with weight savings compared with traditional sealants and will be used on production A350-1000 airplanes to benefit operators.

#masking #aerospace #pollution control

Ecoat Clinic: High Throwpower Impacts Ecoat Performance

Q. Why is high throwpower so important to the overall applied cost for an electrocoat system? What specific elements of the system are affected by it? How can I measure the throwpower effect?

80 Years Helping Finishers

Our readers share how Products Finishing has helped their careers as the magazine celebrates its 80th year covering the finishing industry.

#curing #pollution control

Axalta Coating Systems Opens Powder Coating Learning and Development Center

Facility serves Axalta’s customers as well as those interested in learning more about powder coatings or advancing their application skills; classes are available in both English and Spanish.

#masking #curing #workforce development

Greenkote Adds Major Anti-Corrosion Coating Capacity in Ohio

The company says that the added equipment will multiply current capacity by nearly two and a half times, enabling the Brook Park facility to process more than 150 tons of parts per month.

#masking

Downdraft Versus Cross-Draft Booths

Q. We are considering a new spray booth, and we’ve read a lot about the different types of airflows. What can you tell me about downdraft booths and cross-draft booths, and what should I consider in adding one to my shop?

#masking #pollution control #curing