Loss of Efficiency

Experiencing a decline in efficiency? Powder coating consultant Rodger Talbert offers ideas for improvement.

#racking #ask the expert

PPG Helps High-End Patio Furniture Maker With Transition

After relocating its operations, OW Lee expanded its partnership with PPG to build a new powder coatings line and train over 200 new hires.

Coating Vending Machine Frames

Performance Powder Coating of Longwood, Florida showcases a recent project completed for Everest Ice and Water Systems.

#photo finish

It's About Perseverance

Products Finishing Editor-in-Chief Scott Francis talks about the importance of in-person trade shows.

#editorial

Graphene Nanotubes Add Conductivity to Powder Coatings

OCSiAl and Erie Powder Coatings announce powder coating formulations designed for EMI and RFI applications.

Registration Open for CCAI’s Two Online Finishing Courses

The Chemical Coaters Association International Finishing Academy is offering two online courses this Fall, Powder Coating and Liquid Coating, each set to begin on October 4, 2021.

Episode 9: Weathering the Supply Chain Storm, Part 1 - Powder Coating

In this episode of On the Line, Quint Towle of powder coating supplier Powder Technology Inc. and Michael Guckes of Gardner Intelligence discuss the current state of the coating materials supply chain and the continuing challenges caused by the COVID pandemic.

Axalta to Showcase EV Battery Coatings

The company will unveil a portfolio of coatings that enhance the performance, durability, safety, and cost of electric vehicle batteries and motors at The Battery Show North America, September 14 -16 in Novi, Mich.

#automotive

CCAI Finishing Education Foundation Presents 2021 Scholarships

This year the CCAIFEF has awarded a total of $17,500 in scholarships to deserving students.

#workforce development #education

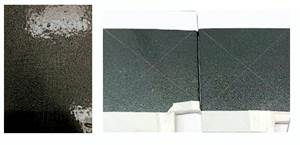

Raising the Bar on Appearance

New system provides improved corrosion protection, paint adhesion and consistent quality at competitive cost.