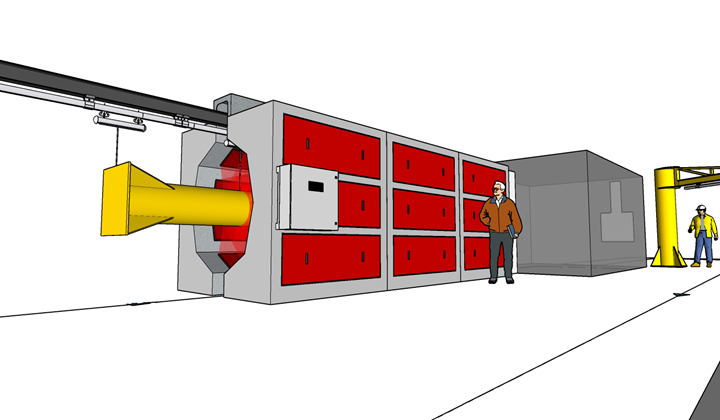

Catalytic Gel Ovens Offer Small Operational Footprint

WolfRayet catalytic gel ovens offer small operational footprints while also providing a way to improve on existing convection curing.

WolfRayet has designed a range of catalytic gel ovens to deliver a more efficient and effective powder coating process. These gel ovens are said to have a small operational footprint and deliver a high-tech, low operating cost solution to improve on existing convection curing.

A longwave IR catalytic gel oven directly heats the powder causing it to gel or fuse. This speeds up the convection oven process and can be useful for those using low-temperature cure powders as well as both textured and higher temperature powders. After gelling, the powder cannot be blown off in the convection oven and this minimizes the chance of cross contamination.

“A catalytic pre-gel oven is a very simple addition to the powder coating process,” says Mike Chapman, chief technical and strategy officer at WolfRayet. “But it can bring significant advantages, including a rapid increase in surface temperature, improved convection heating efficiency and the potential for increasing line speed, enabling greater throughput. What’s more, oven maintenance is greatly reduced, which can be a huge time and efficiency saver.”

With decades of curing and oven experience, and developments in oven technology, WolfRayet says its oven products are carefully designed and produced to deliver a well-suited curing process to improve efficiencies and line savings.

WolfRayet | 940-336-1120 | wolfrayet.com

Related Content

-

Coater's Innovations Deliver Customer-Centered Success

Continuous growth in its powder coating and electrocoating capabilities has enabled Winona Powder Coating to expand its customer base to reach many industries while building relationships.

-

Surface Finishing's Role in U.S. Defense Manufacturing

With a renewed focus on domestic defense manufacturing, meeting specifications, navigating certifications and innovating are areas in which surface finishers have the opportunity to fill.

-

Lightweighting Challenges: Coatings for Next-Gen Vehicles

With demands on the auto industry to incorporate more lightweight structural materials in vehicles, coatings manufacturers are challenged with developing coatings that are compatible with a variety of different substrates.