Anodizing for Bonding Applications in Aerospace

Anodizing for pre-prep bonding bridges the gap between metallic and composite worlds, as it provides a superior surface in many applications on aluminum components for bonding to these composites.

#aerospace #basics

More materials for aerospace manufacturing are coming from the composite world, which then must be used in conjunction with—and joined to—metals. These composites are experiencing huge growth because they allow manipulation of the properties of the composite metallic hybrids to take advantage of the properties of each.

Anodizing for pre-prep bonding bridges the gap between the metallic and composite worlds, as it provides a superior surface in many applications on aluminum components for bonding to these composites. The anodic coating is integral to the base metal, and the porous anodic film is wondrously receptive to primers and adhesives.

Featured Content

There are both mechanical and chemical options for surface preparation. The mechanical option is typical vapor blast with aluminum oxide, roughing up the surface to provide a greater area for bonding agents to adhere. Forest Products Laboratory (FPL) etching is a common chemical method to provide a rough surface for bonding. FPL etching is a mixture of sodium dichromate and sulfuric acid that may be used as a standalone pretreatment for bonding or in conjunction with an anodizing process. The specification that covers FPL etching is ASTM D 2674-72.

Anodizing provides a superior method in most cases for coating adhesion. It also provides other properties, particularly corrosion protection. The characteristics of anodizing that make it attractive over mechanical finishing are predictability, repeatability, consistency and testing verification.

Chromic acid anodizing has been around for a very long time. This proven anodic coating produces a uniformly thin anodic film that provides a porous foundation for a very strong bond with pre-adhesive primers. The challenges with chromic acid anodizing are the hex chrome electrolyte, higher waste treatment costs, health risks associated with chrome exposure, higher regulatory standards and equipment maintenance. AMS/Mil Spec 8625 is the guiding specification for this process.

The boric sulfuric anodizing process is a mixture of boric and sulfuric acids used with conventional rectification. This process—a replacement process for chromic acid anodizing pioneered by Boeing Aircraft—is a thin-film anodic coating designed to provide some corrosion protection and a mechanical bond. Drawbacks include higher operating costs and low volume requirements.

Thin-film sulfuric is a direct replacement for the boric sulfuric process. It is easier for finishers to provide since it uses the anodizing tanks and equipment in use for conventional anodizing. It is not commonly used as a pre-adhesive base for structural bonding. The thin-film sulfuric process is also covered by the AMS/Mil Spec 8625 specification, Type IIB and AMS 2470.

Phosphoric acid anodizing is the most widely used anodizing process for general pre–prep bonding today and provides an excellent base for pre-bond primer applications. One drawback of the process is the lack of inherent corrosion protection on surfaces that would not be primed and bonded. The durability of the phosphoric acid coating is considered minimal. ASTM D 3933-98 describes the phosphoric acid anodizing process for bonding applications; the applicable Sikorsky/UT specification is SS8482.

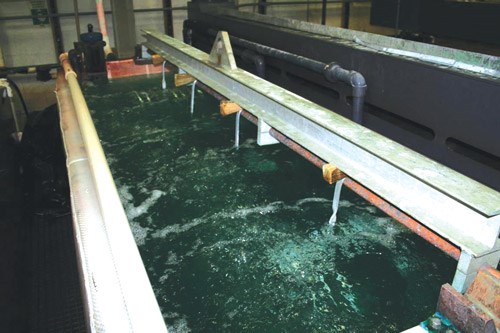

Parts are prepared for chromic acid anodizing pre-bonding

In almost all cases, the general specifications covering the anodizing processes are the AMS or Mil Specification. The chromic and thin-film sulfuric processes are covered by spec 8625. The phosphoric acid process is outlined by spec 3933-98. Most aerospace manufacturers take the general specifications and expand on them to provide a higher level of performance for their application. Sikorsky, Goodrich, Rolls Royce, BAE Systems, GE, Pratt and Whitney, United Technologies, Northrup Grumman, and others all have their own specifications.

Environmental factors are an important and significant management issue for all of these anodizing processes. Chromic acid anodizing requires the management of hex chrome solutions. The EPA approved fume suppressants for foam blanket management, but fume suppressants are not allowed in chromic acid anodizing systems used for primer and bonding applications because they cause adhesion problems. Sikorsky has eliminated Type I chromic acid anodizing and replaced it with either phosphoric or thin- film sulfuric.

Phosphoric acid anodizing is fairly easy to manage compared to hex chrome. Waste treatment is often a simple pH adjustment. The lead cathodes used in phosphoric acid anodizing have been replaced with stainless steel to eliminate lead from the waste stream.

Phosphoric acid anodizing taking place after the pre-bonding.

Thin-film sulfuric acid anodizing is the easiest process to manage. The anodizing line is standard sulfuric acid anodizing chemistry with standard waste treatment requirements. Poly-Metal Finishing uses acid reclamation to manage the aluminum levels in the anodizing tanks.

The practical shop considerations for these different processes are significant. FPL etching, for instance, requires careful part handling. Parts must be handled with gloves after processing to keep oils from the skin off the parts. Post-rinses must be kept very clean, with DI spray required as a final step. No residual acid from the FPL etch process may remain on the parts, because it will react with primers and adhesives causing adhesion failures. Compressed gasses may be used to blow off parts but not compressed air.

Chromic acid anodizing uses standard pretreatment for cleaning, etching and deoxidizing of parts. Rinsing is very important to maintain clean process tanks and prevent cross contamination. Once parts are started in the process, they are kept moving until they are finished. DI water is required for all rinsing. No steel is allowed in the process.

Phosphoric acid anodizing also uses conventional pretreatment chemistry. The tank must be kept covered when not in use to keep bacteria from growing. It also is best to keep wood and other organic matter away from the tank to minimize bacteria growth. In this case, titanium is the only racking material allowed because titanium won’t anodize. No compressed air is allowed in this process as well. Parts are dried in an oven in a clean room. Clean rinsing with a minimum of 5 min dwell time is required. The last step is spray DI water.

Thin-film sulfuric anodizing follows standard industry practices to produce a good, quality coating. Post-anodizing rinses are important to remove any residual chemistry from the process. This process does allow/require the coating to be sealed in dichromate solution for corrosion protection. No air is used to dry the parts, which are dried in an oven in a clean room.

Anodizing plays an important role in bridging the gap between the metallic and composite worlds. The anodic coating provides a great base layer for prime and bonding, and can provide additional protection to the part. The characteristics of predictability, reproducibility, repeatability, consistency and test verification make anodizing a superior choice to mechanical preparation for pre-prep bonding and priming for aerospace applications.

Jason Kudelka is owner and president of Poly-Metal Finishing Inc. and can be reached at 800-628-8356 or poly-metal.com. Christian Ebbrecht is the principle of GetColored Inc. and can be reached at 207-251-0389 or getcolored.com.

RELATED CONTENT

-

Top Shop Aces Outstanding Customer Service

More than a finishing shop, this anodizing, powder coating and vacuum resin impregnating business goes above and beyond for its customers by being a resource for whatever their finishing needs might demand.

-

Trivalent Chrome Overview

As the finishing industry begins to move away from the use of hexavalent chromium to trivalent chromium, what factors should finishers consider as they make new investments? Mark Schario, chief technology officer for Columbia Chemical offers a helpful overview of this complicated topic.

-

Switching from Hexavalent to Trivalent Chromium Plating

There are advantages and disadvantages of moving from hexavalent to trivalent baths. When considering this choice, gather the facts from this article in order to make a well-educated decision.