Top Shop Aces Outstanding Customer Service

More than a finishing shop, this anodizing, powder coating and vacuum resin impregnating business goes above and beyond for its customers by being a resource for whatever their finishing needs might demand.

#topshops

Besides the two facility additions it has completed since its inception, it recently finalized an exterior building refurbishing. This consisted of the addition of new windows for improved visibility and curb appeal.

Source (all photos): Ace Anodizing and Impregnating Inc.

Because the finishing industry can be highly competitive, most shops in this market seek to provide products and services that bolster their reputation and outshine other finishers. However, sometimes excellence occurs naturally while simply being a customer-focused organization, which is the case for Ace Anodizing and Impregnating Inc. (Hillside, Illinois). This Products Finishing Top Shop not only considers itself an expert in the finishing industry after more than 60 years in business but also, living up to its name, an “ace” in the customer service department. Its team does this by offering turnkey work and flexibility that is not the usual services found at most finishing shops.

“Our customers are trying to do more with less people,” says Mike Battaglia, V.P. sales and marketing at Ace. “So, the more of a resource you can be, the more value you can bring, even if it isn’t directly related to something you do.”

Featured Content

He explains that the company sees itself more as a project manager than just a finisher. Therefore, the team often gets involved in the initial design stage of a customer’s project to engineer around any potential finishing barriers and design issues. This way, it gets a true understanding of a product’s end use to provide the correct coating.

A coat of many colors

As its name states, Ace Anodizing and Impregnating Inc. provides anodizing, powder coating with a chromate conversion pretreatment and vacuum resin

The company’s precision cutback saw system is designed for production cutting of bars or extrusions to close tolerances. The system uses a computer controlled back gauge for accurate sawing performance and i mproved throughput.

impregnation capabilities, but offers a lot more than what is implied and to a colorful customer base as well.

The company’s anodizing processes include bright dip anodizing, Type II anodizing, Type III hard coat anodizing and two-step architectural anodizing in clear and a variety of colors. With two anodizing lines, Ace can process small and large parts. It also does vacuum resin impregnation, powder coating, chromate conversion and precision cutback sawing.

Ace’s newest capability is the ability to offer Type III, clear or black anodizing on parts up to 282 inches long. The powder coat system is designed to run parts as large as 24 ft. by 10 ft. by 8 ft. All processes are completed in its original facility, which, after a couple of expansions, now stands at 85,000 square feet.

The components of this large tank, which were fabricated from heavy gauge steel, were to spend their service life as integral tanks in a heavy duty parts washing system. Ace’s customer had specific requirements for the coating, such as the application of a iron phosphate pre-treatment and a fluropolymer custom color, all of which were necessary to guarantee the coatings performance and meet the design requirements. They also had specific requirements for packaging to protect the parts through shipping and rigging prior to the system installation. The company’s ability to powder coat and oven cure large, heavy parts enabled it to powder coat each of the eight 500-lb, 14’ L x 4’ W x 8’ H tanks and related components in five days.

The third-generation, family-owned business serves an intentionally diverse customer base comprised of recreational, medical, aerospace, defense, ordnance, cabinetry, architectural, infrastructure, RV and marine industries, to name a few. Battaglia describes the facility’s range of work. “No job is too small or too large. We have the flexibility to adjust our capabilities to the needs of our customers. The industry is constantly evolving, and so is Ace.”

Part jobs range anywhere from an inch to 282 inches long. “We can anodize and powder coat small parts or a tank that’s 20 ft. long,” he says.

According to Battaglia, the company provides some unique processes that are hard to find in the industry. This includes large part hard coating in clear or black (and any type of anodizing for large parts) and chromate pretreatment on all powder coatings. “Some companies that have their own powder coating operations send us their jobs to pretreat,” he says.

Bright dip anodizing is another increasingly difficult process to find, which

The company’s anodizing processes include bright dip anodizing, Type II anodizing, Type III hard coat anodizing and two-step architectural anodizing in clear and a variety of colors. With two anodizing lines, Ace can process small and large parts.

Ace provides.

The company’s wide range of work that spreads across many industries is strategic, according to Battaglia. “Customer diversity is good because we are not dependent on one industry,” he explains. “We’re able to shift our focus if one industry seems to soften.”

Turnkey tales

As a 20-year veteran in the finishing industry (12 of those years with Ace), Battaglia says Ace is a company focused on getting things done; it has reacted and adjusted quickly to change. Management has responded to customer needs in big ways such as investing in additional processes and equipment which necessitated facility expansion. It also began offering value-added services, or turnkey work, that speaks volumes to its customers.

“If there’s a service that we don’t want to add as one of our core competencies, then we form a strategic alliance with outside sources to provide it,” he explains. “Then, we offer customers the opportunity to either work directly to the provider, or we will turnkey it for them.”

So, if a customer is running into a problem where it can’t find a source for a certain finish, Ace can do some research for the customer to find the solution.

Ace can also take a project from start to finish. For instance, if the customer does not want to buy extrusions, the shop will deal directly with an extruder, purchase the material, bring it in the warehouse and stock it, cut the raw extrusions to precise lengths, finish it and ship it to meet the customer’s specifications. In these cases, Ace acts as a one-stop shop because the customer’s only touch point is the finishing shop. In addition, the customer was not stuck with excess inventory that is the wrong color, wrong length or the wrong finish. Instead, Ace keeps the inventory for the customer and the customer sends Ace its orders as needed.

Staying on top of the game

Reinvesting in the business and evaluating options for continuous improvement are ways Ace lives out its Top Shops title, according to Battaglia.

“The business has changed, the customers are more sophisticated, competition is more sophisticated, and the days of just trying to stay status quo are gone,” he explains. “You’ve got to be coming up with new and creative ways to lower costs, keep good employees and improve your processes.”

Battaglia says Ace’s owner not only does all these things, but he genuinely cares about his employees. Because the staff feels appreciated, in return, it prides itself on producing a quality product. Employees also self-evaluate for process improvement.

To assess the business regularly, the finishing shop finds great value in participating in PF’s Top Shops benchmarking survey each year. “The survey forces us to look outside of our building to see what other finishers are doing,” Battaglia says. “And while we are an industry leader, there are some things out there that others are trying that may be a fit or spark an idea for something we can do differently.”

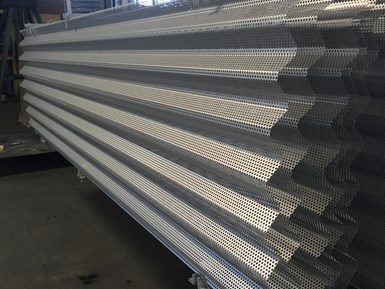

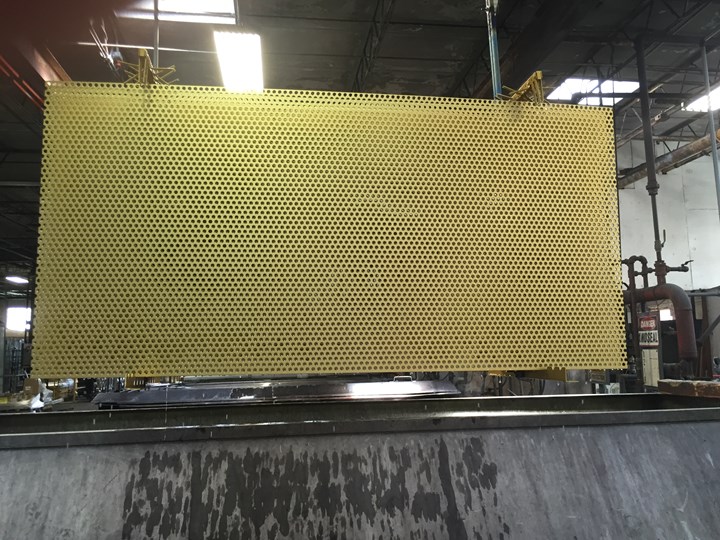

This perforated aluminum panel is used in an architectural application requiring an anodized finish, Type II, Class II, with lightfast, UV stable coloring.

Like many manufacturing companies, Ace is faced with ongoing obstacles such as employee recruitment and the increasing costs of retaining good employees. Cost containment and dealing with rising prices within the supply chain, increased environmental regulations and economic uncertainty are other business challenges.

As there will always be issues to confront within the market or the business itself, change is inevitable as well. The finishing shop strives to adapt as much as possible to the ebbs and flows. Sometimes, that is in the form of building expansions. Besides the two facility additions it has completed since its inception, it recently finalized an exterior building refurbishing. This consisted of the addition of new windows for improved visibility and curb appeal.

RELATED CONTENT

-

Powder Coating Aluminium Adhesion Failure

PF columnist Rodger Talbert offers advice for mitigating adhesion failure of powder coating on aluminum parts.

-

10 Anodizing Best Practices

Following this list of guidelines can help to increase the performance, cost effectiveness and quality for your anodizing operation.

-

Powder Coating Week 2024 Offers Education and Networking

On March 11-13, 2024, this event for powder coaters will combine training, presentations, technical sessions, tabletop exhibits, roundtable discussions, expert panels and social activities.