Single and Available

A look at one-step cleaner/pretreatment processes

You know they're out there—single-stage cleaner/pretreatment processes that promise to save energy, cut waste disposal costs and streamline your finishing operation by saving time and floor space. But how do they work, and are they applicable for your parts?

To find out, PF asked two suppliers of such processes to answer a few questions. Our respondents are Carl Landon of BioClean, USA (Bridgeport, CT) and Mary Carpenter of Carpenter Chemicals LLC (Alexandria, VA). Here's what they had to say.

Featured Content

Products Finishing: Please give our readers a description of your process—how it works, what types of equipment it works in, process temperature range, control methods and so on.

Mary Carpenter: Plaforization has been available for many years world-wide and is in use by more than 500 customers. Toran is a new product, in the final pre-launch stage and set to be released in the next couple of months. It operates on the same one-step, no-rinse, room-temperature principles as Plaforization. Both are true one-step processes to clean, phosphate and seal metal surfaces. With either process, parts are treated for one minute, dripped off and dried, and are ready for painting.

Plaforization uses no water and is not rinsed. It operates at room temperature and creates no sludge or other wastes. Users save money because of the lower capital cost of equipment, and because there is no heating, no water, very little electricity (fewer and smaller pumps and fans) and very little of the labor associated with conventional system operation and maintenance.

The bath is extremely stable because the chemistry stays in balance. Solution ingredients are used up in proportion, oils are absorbed and used in the process, and any metal fines that come in on the parts are continuously filtered out. Bath samples are taken only every two months.

Application can be via dip or spray at very low pressure (3-5 psi), and can be continuous, indexed or batch. Anything that comes in contact with the treatment liquid must be made of stainless steel, polypropylene or polyethylene.

The process, whether dip or flowcoat, consists of a one-minute treatment stage followed by drip-off and drying. Normally, drying takes place in an oven at 300°F for 4-5 min. However, for small-batch production one of the products can be dried at room temperature in a little over half an hour.

The system requires virtually no maintenance. There is no waste to treat or dump and no de-sludging of the tank. Nozzles do not plug up because of the lack of sludge. About the only maintenance required is changing filter bags.

Carl Landon: BioClean's patented cleaner/phosphate technology combines a highly effective cleaning system with iron phosphate so parts are cleaned and iron phosphated in a single process step.

The process employs a highly efficient cleaner chemistry and harmless microbes that naturally occur in the environment to consume oils and soils cleaned from the parts, thus releasing the detergents back into the cleaning bath so it becomes self-regenerating. We have installations that are more than seven years old and have never been dumped!

BioClean, USA cleaner/phosphate products are used in spray washers (with any number of stages as are available), in immersion systems, by deluge or in "pressure island" type installations. BioClean products normally run at concentration of 1-5% by volume, a temperature range of 105-135°F and pH of 5-5.5. We are currently developing both cleaners and cleaner/phosphates that operate at even lower temperatures.

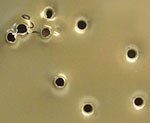

Process time in a spray application is 1-2 min. Stainless tanks are recommended, but the product can also run in mild steel or polypropylene tanks. The population of bacteria in the process solution is huge—tens of millions of microbes per cubic centimeter.

A control module supplied by BioClean automatically monitors and replenishes the pretreatment solution to maintain proper operating conditions, while a pump provides constant circulation of the solution. The control module removes suspended solids, including a small quantity of dead bacteria.

BioClean cleaner/phosphate chemistries are available in several variations optimized to handle different types of oils and greases.

Suitable Applications

PF: What types of applications are suited to this cleaner/pretreatment approach?

MC: Plaforization can treat almost any metal—steel, aluminum, galvanized, galvanneal, brass, magnesium and others, and can do so simultaneously in a single bath. It is also used by some customers to treat highly polished metals and stainless steels because it very effectively promotes adhesion of the topcoat to the very smooth metal and provides both a chemical and a physical bond to the topcoat.

Plaforization is used to treat parts for all kinds of indoor and outdoor applications. It works with powder coatings and water- and solvent-based liquid paints. A new modification of the polymer used in Plaforization will be available very soon and has been shown in laboratory tests to very significantly improve adhesion.

Also new is Toran 3, which uses a completely new method of bonding the polymer resin to the metal to offer improved adhesion, impact resistance and corrosion resistance. Toran 3 will be aimed at higher-end performance requirement applications, such as those that might use zinc phosphate pretreatment.

CL: BioClean cleaner/phosphates are used in both job shops and captive shops. They are used as a pretreatment for powder coating, solvent and water-based paints. Because of BioClean's strong presence in job shops, BioClean cleaner/phosphates are used to treat virtually any metal part that is painted from shelving to agricultural equipment to automotive parts.

Contract finishers often receive parts in varying degrees of cleanliness with a wide variety of ols/soils, and this presents no problem for the BioClean process. Micro-organisms multiply as oil volume increases to maintain degreasing efficiency. Near-neutral pH and low process temperature ensure cleaning of all materials without etching. The system is ideally suited for cleaning parts prior to plating, painting, powder coating or hot-dip galvanizing.

BioClean has successfully converted many different systems to our one-step cleaner/phosphate with no problems. We process cold rolled steel, hot rolled steel, hot rolled/oiled steel, aluminum, galvanize and magnesium substrates. Heavy oil loading is not a problem and we regularly run oil loads in excess of 200 g/m2

Best Left to Convention

PF: What types of applications are probably best left with a conventional pretreatment process?

MC: There are a couple of major areas that are contra-indicated for these products. These include applications in which the parts to be treated are rusty, or have mill scale or laser dross on them. Such surface contaminants must be removed before either of the processes can be used successfully.

Another area of concern is treatment of parts covered with high-melting-point waxes such as paraffin or animal fats such as calcium stearate. Plaforization and Toran processes and solvents are designed to work with normal process oils such as mineral oils, including water-emulsified oils if the parts are completely dry prior to entering the bath.

There is also an economic upper limit on production. At very high production, cost savings deriving from Plaforization's operating benefits can be outpaced by the cost of the chemistry.

The Big Switch

PF: What is involved in switching from a conventional pretreatment processes to your process?

MC: Any equipment in contact with the treatment liquid must be stainless steel, polypropylene or polyethylene. In spray systems, there are differences in liquid pressure and air flow. Our process operates at 3-5 psi rather than at the much higher pressures of conventional pretreatment, so risers and nozzles must be modified.

Air flow in a conventional process creates lots of pressure, atomization and chemical-laden steam, which must be removed from the treatment area and the plant by means of a strong exhaust flow. It's almost the reverse with the one-step organic process: chemical vapors are much heavier than air and will sink if left undisturbed. Chemicals are recycled and re-used in the process by designing the system with only very minimal air flow out from the ends of the treatment tunnel, as far from the spray zone as possible. Air curtains or polyethylene curtains placed at strategic locations in the tunnel reduce air flow in the tunnel, and most importantly in the spray zone, to avoid wasting the treatment chemicals.

So, an existing system can be converted if it is new enough to make it economically feasible and if it is a stainless steel system at least in the treatment area and tank. Changes must be made to the risers, nozzles, pumps and filters to adjust liquid and air flows. And, the tank itself will almost certainly be much smaller than the conventional tank, because the low-pressure spray requires less reserve in the tank to feed the risers and nozzles.

CL: BioClean cleaner/phosphate products may be substituted for existing conventional systems in both immersion and spray applications. No additional exhaust or scrubbers are required, as the products have no odor and are VOC-free.

Conversion is straightforward. Users simply drain the existing products and rinse out tanks and piping. If the system to be converted is heavily scaled we recommend power washing or (in extreme cases) chemical stripping before conversion. In multistage equipment, any "extra" stages are converted to counterflow rinses. If counterflow rinses are not in place we recommend that this be done at changeover, because this saves massive quantities of water (and associated costs of treatment). Generally this is not difficult and is done by the maintenance staff at the customer. When counterflowed rinses are incorporated, the BioClean process becomes "closed loop" with almost no water or solution going to the drain.

RELATED CONTENT

-

Zinc Phosphate: Questions and Answers

Our experts share specific questions about zinc phosphate and pretreatment

-

VDA 19 and its Impact on European Manufacturing and Cleaning

The German Association of the Automotive Industry’s VDA Volume 19 is the first comprehensive standardization document for characterizing the cleanliness of products within the automotive industry’s quality chain.

-

Conversion Coatings: Phosphate vs. Zirconium

Both phosphate-based and zirconium coatings have their advantages, but zirconium is fast becoming the pretreatment of choice.