Metal Finishing Facility Released Hexavalent Chromium into Huron River

Wastewater discharge of hexavalent chromium into Huron River results in “no contact” health advisory, sparking calls for more stringent pollution controls and automotive industry action to reduce hexavalent chromium uses.

#pollutioncontrol #nasf #regulation

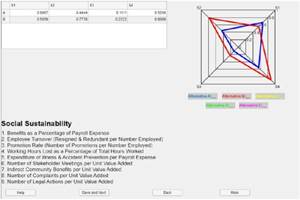

NASF/AESF Foundation Research Project #121: Development of a Sustainability Metrics System and a Technical Solution Method for Sustainable Metal Finishing - 8th Quarterly Report

This NASF-AESF Foundation research project report covers the eighth quarter of project work (January-March 2022) at Wayne State University in Detroit. The major activities in this report period are: (1) the development of a sustainability assessment method for technology evaluation with case studies, and (2) a continuous development of a software tool for sustainability assessment.

#sustainability #nasf #measurement-testing

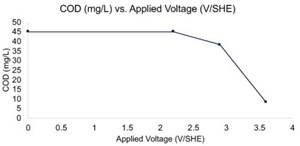

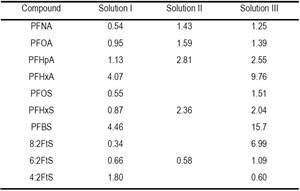

NASF/AESF Foundation Research Project #120: Electrochemical Destruction of Perfluorooctanesulfonate in Electroplating Wastewaters – 7th & 8th Quarter Report

This NASF-AESF Foundation research project report covers the seventh and eighth quarters of project work (October 2021-March 2022) at the University of Illinois at Chicago. The major activities reported are: (1) to investigate 6:2 FTS oxidation, a common replacement compound for PFOS in the electroplating industry, and (2) PFAS oxidation in both a wastewater sample procured from an electroplating facility and in synthetic solutions.

#asktheexpert #pollutioncontrol #nasf

NASF/AESF Foundation Research Project #123: Electrochemical Manufacturing for Energy Applications - 1st Quarterly Report

For 2022, NASF-AESF Foundation Research Board has selected a project on electrodeposition toward developing low-cost and scalable manufacturing processes for hydrogen fuel cells and electrolysis cells for clean transportation and distributed power applications. This report introduces the project and outlines the work to be undertaken.

#nasf #additive-manufacturing

Register Now for NASF's Airline & Aerospace Finishing Course

The course provides attendees with a broad range of information related to metal finishing operations that are common in the airline/aerospace industry.

#nasf #aerospace

Non-PFAS Wetting Agents for Decorative Chromium(VI) Plating

This article is based on a presentation given at NASF SUR/FIN 2022, in Rosemont, Illinois, in Session 6, Responses to PFAS / PFOA. It follows the case study of three facilities’ conversion from PFAS-containing wetting agents to non-PFAS equivalents, eliminating PFAS and moving forward with a smaller and more sustainable environmental footprint. The journey of conversion from PFAS-containing wetting agents in both chromic-sulfuric etch and hexavalent decorative plating tanks can be complicated and winding due to deep rooted standard industry practices, as well as state and federal regulations. Outlined here is a clear course of action that led to eliminating PFAS from the facilities’ wetting agent strategies.

#sustainability #automotive #nasf

Building Momentum for the Future of the Finishing Industry

Products Finishing editor-in-chief Scott Francis offers a quick recap of this year’s SUR/FIN surface finishing industry trade show.

#nasf #surfin #editorial

PFAS Legislation Introduced That Specifically Targets Surface Finishing

Legislation was recently introduced again in Congress that would require EPA to issue wastewater discharge limits for PFAS for electroplating and metal finishing source categories. Among other impacts, the measure would accelerate the PFAS rulemaking on which NASF is already working with EPA.

#nasf #regulation

CARB Releases Draft Regulatory Language for Chromium Plating Rule

In draft regulatory language, CARB bans hexavalent chromium plating processes, prohibits any new hexavalent chromium permits, and imposes strict new control measures until the bans take effect.

#nasf #regulation

SUR/FIN Session to Focus on PFAS, Chromium Plating and Automotive Supply Chain

Experts from the surface finishing industry, representatives from several automotive OEMs, and government officials will be part of a technical session at SUR/FIN on June 7, 2022 that will focus on the barriers and incentives associated with chromium plating in the automotive supply chain.

#nasf #regulation #surfin

NASF Releases May 2022 Policy Update

The National Association for Surface Finishing has released its monthly Policy Update, summarizing some of the pertinent regulatory developments and new announcements from the month of May.

#pollutioncontrol #nasf #regulation

Pentagon Halts Incineration of PFAS Containing Materials

The Department of Defense announced that it was temporarily stopping the incineration of PFAS-containing materials until it can issue appropriate disposal guidance.

#pollutioncontrol #nasf #regulation

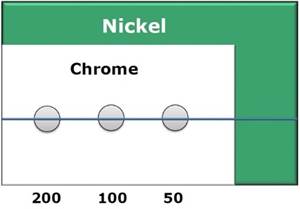

Developing Standardized Testing for Trivalent Chromium Thickness: A Progress Report

The industry shift toward trivalent decorative chromium plating and away from hexavalent highlights a need for testing standards. As Chair for ASTM B08.10 Subcommittee on Test Methods for Metallic and Inorganic Coating, Mark Schario is leading the committee’s focus on developing standardized testing for trivalent chrome thickness. This presentation provides information on the initiative, testing methods and variables, initial data on thickness comparison and alloy composition, and summary of input and extended lab testing.

#regulation #nasf #surfin

NASF/AESF Foundation Research Project #122: Electrochemical Approaches to Treatment of PFAS in Plating Wastewater - 4th Quarterly Report

The NASF-AESF Foundation Research Board has selected a project on addressing the problem of PFAS and related chemicals in plating wastewater streams, studying PFAS destruction via electrooxidation and electrocoagulation. This fourth quarter report continues the work on electrocoagulation and electro-oxidation, measuring energy consumption and evaluating methods to remove residual zinc ions from the floc after processing.

#pollutioncontrol #nasf

An Interview With... Tony Revier, Uyemura International

Products Finishing recently spoke with Tony Revier about his thoughts on association work, the future of the industry and his career in metal finishing.

#nasf #finishinghalloffame

NASF New England Chapter to Hold In-Person Seminar

The seminar will cover training for the Resource Conservation and Recovery Act (RCRA), as well as hazard communication.

#workforce development #nasf

NASF/AESF Foundation Research Project #121: Development of a Sustainability Metrics System and a Technical Solution Method for Sustainable Metal Finishing - 7th Quarterly Report

Development of a Sustainability Metrics System and a Technical Solution Method for Sustainable Metal Finishing

#nasf #sustainability

Talking Finishing Regulatory Policy

The National Association for Surface Finishing recently held its Washington Forum – a great event providing insight into policy discussions on the table in D.C.

#nasf #regulation #photo finish

NASF Offers Online Aluminum Finishing Course

NASF’s Aluminum Finishing course consists of 11 modules over 16 training sessions, each one containing theoretical and practical information for employees and supervisors who apply anodizing and other finishing processes to aluminum.

#nasf

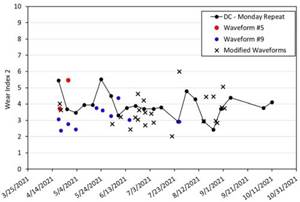

Improving the Wear Performance of Functional Trivalent Chromium Plating Via Pulse-Reverse Electrodeposition

This paper covers work on improving the wear performance of a functional chromium coating from a trivalent chromium plating bath. Wear resistance is a critical aspect of chromium coatings when used in components of both ground-based and aerospace vehicle systems. Traditional hexavalent chromium coatings have shown exceptional wear resistance in these applications, while the wear resistance of trivalent chromium coatings has been less satisfactory. Using pulse-reverse electrodeposition to control various characteristics of the chromium coating, the wear performance of trivalent chromium plated panels could be improved. A multivariate regression model of the electrodeposition conditions shows that bath chemistry parameters within the range of viable plating are not a large contributor to the variance in wear performance, while the roughness and size of macro-cracks is very important for wear-related applications. The multivariate analysis approach undertaken in this study may find potential applications in broad areas of the plating and finishing industry.

#aerospace #automotive #nasf