Pre-Plate Finishing

We chrome plate a small aluminum fitting, first using a vibratory process on the part to produce a competitive, refined, pre-plate finish. This often creates small part dings and surface orange peel that only show up after plating. What causes the surface damage, and how can we test for part damage on the hard-to-see-through matte finish prior to plating to avoid an expensive strip and re-plate process?

High-Energy Mass Finishing

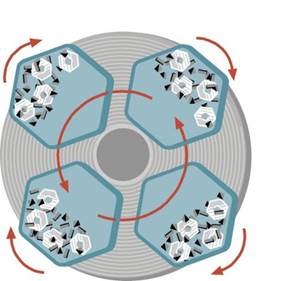

We produce two parts that cannot be deburred in our bowl vibratory machine. Is there another finishing system that would deburr these parts?

#energy

SBA Mentor-Protégé Program

Will the federal mentor-protégé programs help improve a small business' chances for a federal contract?

Vibratory Residue Problems

How can we remove the white residue left on parts after vibratory finishing without an expensive, additional cleaning/drying operation after finishing?

Pre-Anodize Vibratory Finishing

What vibratory media would provide a good visual finish on clear and black anodized aluminum parts?

Guarding Against Counterfeit Parts

We have been doing a lot of defense work lately and are concerned about counterfeit parts. How can we protect ourselves?

#basics #military #pollution control

Supplier Contracts

Can we (the supplier) refuse to agree to early termination of a contract unless the customer agrees to increased prices or other concessions?

Breaking Old Mechanical Finishing Habits

Changing the process earns one finisher a $2+ million annual contract, therefore when we look at mechanical finishing, the first and most important items that should be considered are the shape and type of part

Media Lodging

Ceramic media chips and small media are lodging in the parts during our vibratory process. How can we prevent or eliminate these problems?

Finishing Aluminum Parts

We are machining a 6-inch, complex-shaped, 6061 aluminum part. We need to further improve the surface finish from the machined 32 Ra to 12 Ra, maintaining a uniform, pleasant finish. What finish system should we consider?