Monitoring Compound Concentration

How can we continuously monitor our mass finishing fluid?

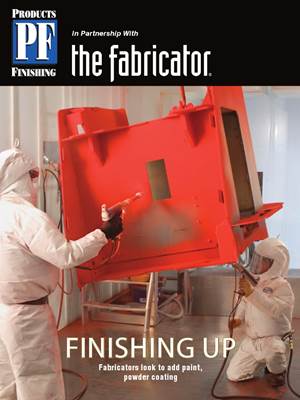

Be All You Can Be

For fabricators, the finishing line is just the beginning of a new era in today's market. The days of simply cutting, bending and welding metal components into assemblies and delivering them to a customer in two to three weeks just don't exist anymore, nor with original equipment manufacturers need tighter turnarounds for their parts.

#economics

Making the Best Choices in Mass Finishing

Choice of equipment, media and compounds has a major impact on your finishing applications.

#basics

Buffing and Polishing— Looking to the Future

Advances in equipment, automation and consumables can help you compete.

#basics

Phosphates in Wastewater

I am charged with finding the sources of phosphorus in our plant. Our main process effluents are from mass finishing and washing machines. I have not found significant phosphorus in these fluids, and yet, we are close to the limit. What am I missing?

#pollution control

Reducing Surface Finishing Costs

We are spending too much on such things as deburring and cleaning of parts after machining or grinding. My assignment is to take a fresh look at our mass finishing operations and come up with a cost saving plan.

Selecting a Vibratory Finisher

Can you recommend selection criteria for buying vibratory finishing machines?

#basics

At Cause and Effect

In essence, we are “at cause” when we are doing everything we can to control our own destiny. Looking ahead, driving change, implementing business improvements, planning strategically, anticipating potential future business problems and then heading them off before they occur are all typical behaviors of an individual in an “at cause” mode.

Better Peening Shouldn’t Be a Shot in the Dark

Almost any pilot will tell you that when it comes to airplane parts like wings or engine blades, failure is unacceptable. That’s why more aerospace companies have sought to reduce the possibility of metal fatigue in such critical parts, and why some manufacturers of those pieces use a technique called shot peening.

#aerospace

Improving Aerospace Engines with Advanced Materials

Advanced ceramics and high performance superalloys are playing an important role in improving aerospace engines as aerospace manufacturers look for high-temperature materials that increase performance, improve fuel efficiency and satisfy safety standards, while at the same time lowering manufacturing costs.

#aerospace