Axalta Wins 3 Edison Awards

Edited by Lori Beckman

Edison Awards winners were recently announced at the 37th annual Edison Awards event in Fort Myers, Florida. This is the sixth consecutive year that Axalta has won an Edison Award.

Powder Coating Collection for Architectural Market

Edited by Lori Beckman

Structura range of Interpon D powder coatings offers 40 of the most popular RAL colors.

Smart Shot Blast Machine with Swing Chamber

Edited by Lori Beckman

Rösler’s compact RWK 6/12-2 swing chamber shot blast machine is equipped with automated workpiece handling and can easily be integrated into linked manufacturing lines, requiring very little space.

Variable Frequency Drives Deliver Intelligent Control of Conveyor Systems

Edited by Lori Beckman

Source: Nordac

Nordac ON/ON+ variable frequency drives (VFDs) deliver intelligent control of conveyor systems with an integrated multi-protocol Ethernet interface to improve efficiency, reduce system variants and optimize performance, the company says.

ECOAT24 Brewer Award Winners

Edited by Lori Beckman

The 2024 Brewer Award Winners were presented with their awards at ECOAT24 at the Omni ChampionsGate in Orlando, Florida on April 4.

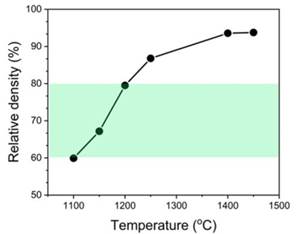

NASF/AESF Foundation Research Project #122: Electrochemical Manufacturing for Energy Applications

This NASF-AESF Foundation research project report covers the ninth quarter of project work (January-March 2024) at the University of Texas at Dallas. In this period, we followed our work on 3D printing anode support for solid oxide fuel cells, SOFC (or cathode for solid oxide electrolyzers, SOEC). We focused on the mechanical properties of 3D printed yttria-stabilized zirconia (YSZ) using a four-point bending test. We then conducted a statistical analysis to characterize the flexural strength of porous 3D printed YSZ.

#nasf

Robert McLaughlin Retires from Axalta Board of Directors

Edited by Lori Beckman

Robert M. McLaughlin has decided he will retire from Axalta’s board of directors and will not stand for re-election at the company’s 2024 Annual General Meeting of Members.

Technic Appoints Director/Research and Development

Edited by Lori Beckman

In his new role, Matt Sylvestre oversees and coordinates all research and development projects at Technic's Cranston, Rhode Island, facility, as well as manage the operations of the R&D laboratory.

Gema USA Welcomes New Controller

Edited by Lori Beckman

Alicia Czyszczon joins the company from USA Comfort Corp. where she served as the controller since 2015.

Columbia Chemical and Alufinish Announce Collaboration

Edited by Scott Francis

By combining their sales and service capabilities and resources for the U.S. market, the two companies will cover the entire aluminum alloy surface treatment process from pre-treatment to anodizing and coating.

#economics

Register for In-Person Finishing Courses from NASF

Edited by Lori Beckman

Three classes are offered during Sur/Fin 2024 in Atlanta, Georgia.

PPG Appoints VP Environment, Health and Safety

Edited by Lori Beckman

Lyndee Brassieur will report to Ram Vadlamannati, senior vice president, operations.