DeburringEXPO Merges with Parts Finishing Trade Fair

Edited by Lori Beckman

DeburringEXPO will no longer take place as an independent event, but will be incorporated into the new trade fair called Parts Finishing, taking place for the first time next year on Nov. 12 – 13, 2025.

Full Lifecycle of Products, Services and Equipment for Finishing Industry

Across industry and around the world, MacDermid Enthone partners with customers to deliver innovative technologies backed by industry-leading service and support.

#surfin

Plating, Anodizing Equipment for Variety of Applications

Edited by Chris Pasion

Titan Metal Fabricators Titan Metal Fabricators, Rightech Fabrications and Optimum Anode Technologies are leading suppliers of equipment for the plating and anodizing industries.

#surfin

Precision and Controlled Depth Electroplating

Highlights of company offerings include the Spouted Bed (SBE) for precision electroplating and the CDP2000 machine for controlled depth electroplating.

#surfin

Senney Enterprises Features Many Companies

This group consists of Met-Chem, Auto Technology, Samsco and Poly Products

#surfin

Silver Dispersion Delivers Performance Package for HF Applications

Unique dispersive technology provides excellent conductivity and superior resistance to tarnish and high temperatures.

#surfin

Mobile Job Shop Software Tour Kicks Off

Edited by Lori Beckman

"The Hatchery Roadshow" brings Steelhead job shop software directly to manufacturing communities.

MRO Benefits from VR Paint Training Technology

Edited by Lori Beckman

The VR technology being used by IAC immerses the individual painter in a virtual paint booth, complete with the aircraft part to be coated.

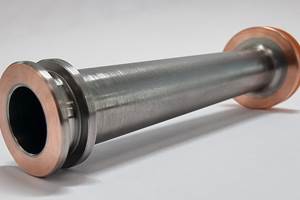

Hardide Coatings Launches First Product in New Ready Coated Component Range

Edited by Lori Beckman

Hardide coated HVOF copper nozzle extends life by up to 40x.

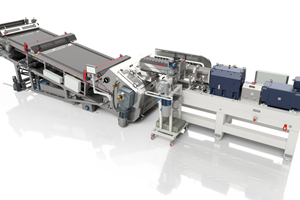

High-Productivity Extrusion and Cooling Systems for Powder Coating

Edited by Lori Beckman

IPCO offers extrusion, cooling and flaking systems for powder paint production.

Axalta Wins 3 Edison Awards

Edited by Lori Beckman

Edison Awards winners were recently announced at the 37th annual Edison Awards event in Fort Myers, Florida. This is the sixth consecutive year that Axalta has won an Edison Award.

Powder Coating Collection for Architectural Market

Edited by Lori Beckman

Structura range of Interpon D powder coatings offers 40 of the most popular RAL colors.