EN and the Rise of the Electric Vehicle

Implications and Applications for Electroless Nickel

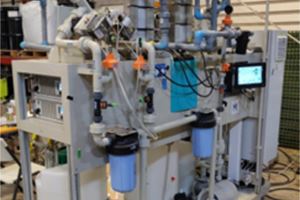

TTX Environmental Solves Customer Issue with Electro-Ceramic Desalination Wastewater Processing

Electroplating facility without access to a drainage system found a safe solution for wastewater treatment and reuse.