Why do some alloys anodize more easily than others? Why do some components manufactured from the same alloy—through the same anodizing process, at the same time, on the same rack—sometimes exhibit different finish appearance and sometimes different finish performance? This presentation gives some answers by connecting anodizing theory to practice. The impact of various phenomena at the aluminum-electrolyte interface will be discussed along with process solutions to yield acceptable finishes with even the most difficult alloys.

Agenda:

- Review of the anodizing circuit

- Impact of manufacturing process on substrate microstructure

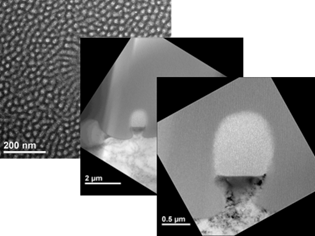

- Interfacial phenomena: their impact on oxide growth

- Anodizing process parameters: their impact and how they can be adjusted to facilitate oxide growth