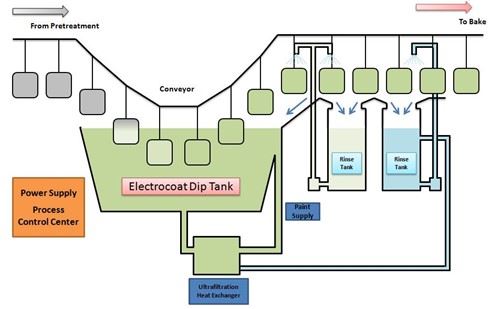

Electrocoating, also called ecoat, is a process by which electrically charged particles are deposited out of a water suspension to coat a conductive part. E-coat is a prevalent finish used in the automotive industry.

Conveyors and Paint Systems

Choosing the right conveyor system, coating technology, and ancillary equipment.

Electrocoating: Essential Reading

Installing an Ecoat Line

Thinking of investing in electrocoating capabilities? George Lovell, coatings plant manager for Lippert, discusses considerations you should keep in mind as you add your ecoat line.

Coating Systems with the Best Long-Term Performance

The best protection against corrosion and UV exposure, says Axalta’s Mike Withers, is electrocoat and a super durable powder coating.

How to Measure Ecoat Throwpower in the Field

Axalta’s Dan Rose says the regular monitoring, recording and charting of throwpower can be a very valuable tool for ensuring quality.

Author: Time for EPA to Lead in 'Real World' Safety Standards

"I implore our new administration in Washington to take the lead and bring good sense and reason back into the regulatory process."

How to Increase Line Density

Q. Our finishing shop applies both liquid and powder applications, as well as some plating, too. How can we increase our racking line density by adding more parts per foot? Racking expert Scott Rempala has the answer.

FAQ: Electrocoating

What is electrocoating?

Electrocoating is a process by which electrically charged particles are deposited out of a water suspension to coat a conductive part. During the electrocoat process, paint is applied to a part at a certain film thickness, which is regulated by the amount of voltage applied.

How can I coat aluminum?

A typical process for plating copper on aluminum is:

- Degrease.

- Soak clean.

- Thoroughly rinse.

- Dip in a 50 percent nitric acid solution. Depending on the aluminum alloy, sodium bifluoride, sulfuric acid or chromic acid may have to be used in conjunction with nitric acid.

- Thoroughly rinse.

- Dip in a zincate bath for 1 minute. (Proprietary zincate solutions are best.)

- Strip the zinc coating using 50 percent nitric acid

- Rinse thoroughly.

- Dip in the zincate solution again.*

- Rinse thoroughly.

- Apply a copper strike using a cyanide or non-cyanide alkaline strike bath.

- Rinse thoroughly.

- Plate in a copper plating bath.

https://www.pfonline.com/articles/copper-plating-on-aluminum-and-aluminum-alloys

How can I estimate the electrocoat usage of a part?

Electrocoat usage per part is usually determined by multiplying the square foot of a part by the ecoat usage per square foot. The square footage should be supplied by the part manufacturer. The ecoat usage per square foot can be determined by two different methods — average and theoretical.

https://www.pfonline.com/articles/estimating-the-electrocoat-usage-of-a-part

Electrocoating Suppliers

Narrow by Electrocoating Category

- Used Equipment

- Thermometers, Pyrometers

- Testing Equipment, Thickness of Coating

- Testing Laboratories, Independent, Water Pollution Control

- Testing Service, Accelerated Weathering

- Testing Equipment, Adhesion

- Testing Equipment, Color

- Testing Equipment, Gloss

- Testing Equipment, Impact Resistance

- Testing Equipment, Paint Film Discontinuity

- Testing Equipment, Paint Film Flexibility

- Testing Equipment, Rectifier Ripple

- Testing Equipment, Salt Spray

- Testing Equipment, Thermal Cycling

- Testing Equipment, Accelerated Weathering

- Testing Equipment, Abrasion Resistance

- Temperature Recorders

- Tanks, Plastic

- Tape, Masking for Plating & Painting

- Tanks, Metal

- Spectrophotometers

- Software for Finishing

- Resins, Paint & Powder Coating

- Rectifiers

- Shop Management Software & Systems

- Rectifier Rebuilding & Repair

- Racks, Plating, Painting & Anodizing

- Racking/Unracking Machines

- Rack Trucks

- Programmable Controllers

- pH Papers

- pH Meters

- Periodic-Reverse Equipment, Current Interrupters

- Paint-Circulating Systems

- pH Electrodes

- Ovens, Infrared

- Oven-Temperature Monitors/Curing Analyzers

- Mixers, Stirrers

- Ovens, Convection

- Ovens, High-Velocity

- Masking, Customized

- Masking Caps, Discs, Plugs

- Magnets, Tank

- Hoses, Air or Liquid

- Humidity Cabinets

- Hoists, Traveling: Automatically Controlled

- Hoists, Traveling: Manually Controlled

- Flooring, Chemical-Resistant

- Heaters, Immersion

- Environmental Test Chambers

- Finishing Systems, Paint, Porcelain Enamel, Powder, Conveyorized

- Current Controls

- Electrical Connectors, Chemical & Corrosion Resistant

- Electrocoatings

- Controls, Rinse Tank Concentration

- Controls, Solution Conductivity

- Controls, Temperature

- Controls, Burner

- Controls, Color

- Burners, Gas & Oil (Combination)

- Burners, Oil

- Coils, Liquid Heating & Cooling

- Ammeters & Voltmeters

- Ampere-Hour Meters

- Associations, Tradeshows & Professional Groups

- Burners, Gas