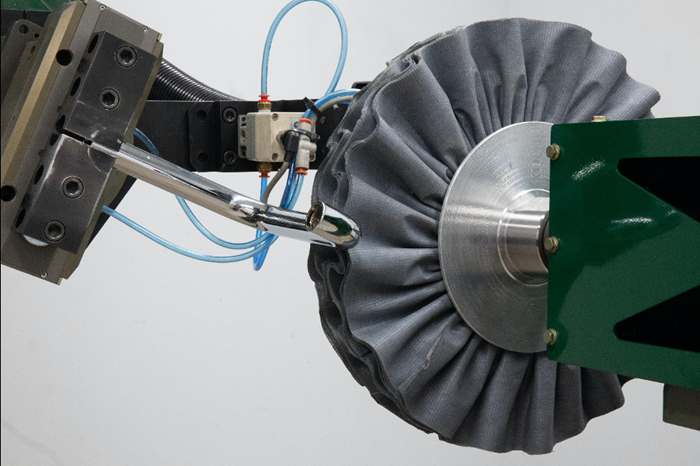

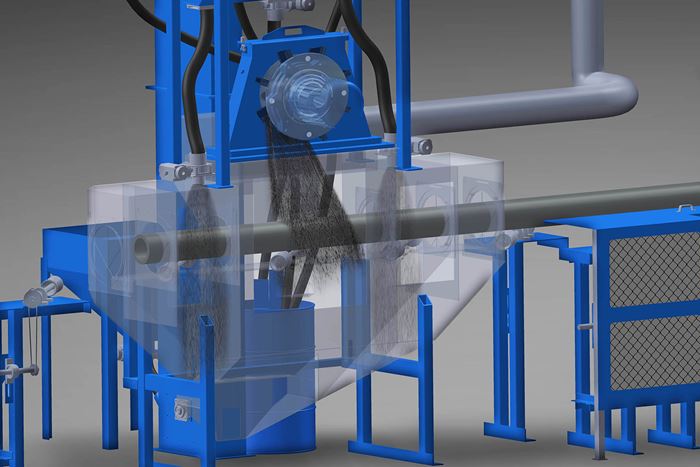

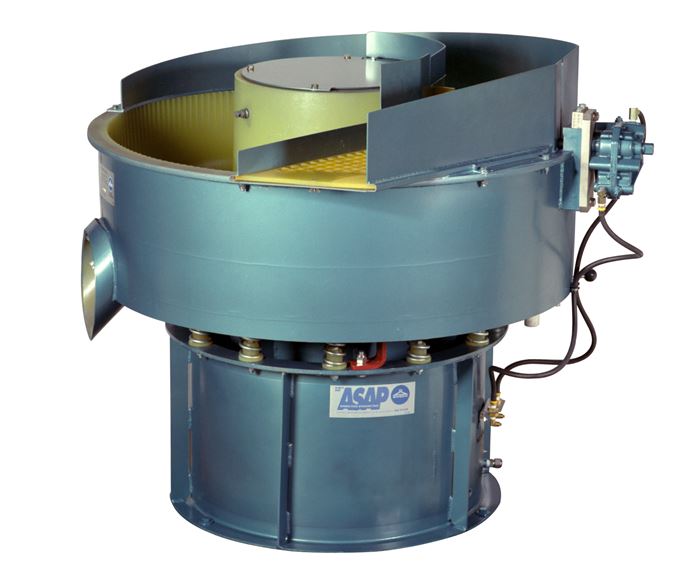

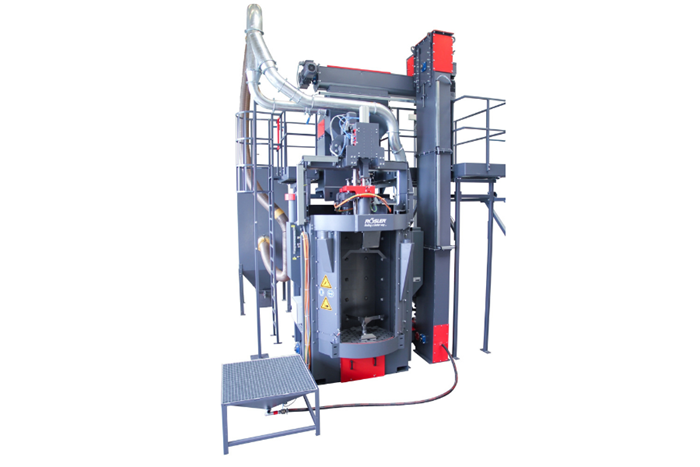

Mechanical Finishing, also known as Mass Finishing, typically relies on motion and force to apply an abrasive material to a part. Processes include tumbling, grinding, vibratory finishing, centrifugal disc finishing, centrifugal barrel finishing.

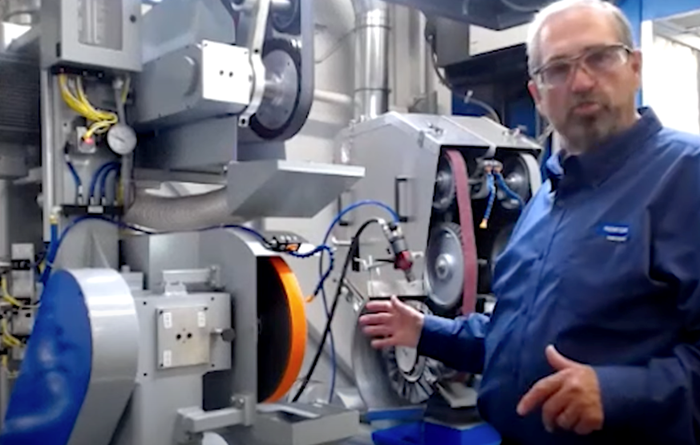

Polishing vs. Buffing: What's the Difference?

Is polishing the same as buffing? Mechanical finishing expert, Pat Wenino, explains the differences between the two processes.

Mechanical Finishing: Essential Reading

The Basics of Automotive Surface Engineering by Isotropic Superfinishing

This paper discusses using a non-abrasive, high density media in conjunction with an isotropic superfinishing (ISF) chemistry. This improved surface significantly reduces friction and provides several engineering advantages. The paper also reviews the technique used to generate ISF and some of the improvements that can be imparted to metal-to-metal contact surfaces.

Tips for Choosing Abrasive Blasting Safety Equipment and Safety Procedures

Selecting new blasting equipment? Lane Barnholtz of Clemco Industries, manufacturer of air-powered abrasive blasting equipment, offers insights for choosing the correct equipment for your needs.

Drivers of Change

Is your metal finishing software ready for an upgrade?

How to Eliminate White Chalky Substance from Vibratory Finished Parts

Q. We are getting a white chalky substance left on our aluminum parts after vibratory finishing and it affects the coating adhesion. How do we eliminate this problem?

How to Produce a Visual Blasted Finish

Q. Can you recommend a process that can give a visual blasted finish?

FAQ: Mechanical Finishing

What considerations do I need to keep in mind as I select blasting equipment?

The information that follows outlines how to evaluate which safety equipment and safety procedures are best for a typical abrasive blasting job. However, before choosing equipment or establishing safety procedures, evaluate the target surface and the worksite environment, perform a job hazard analysis, and assess the goals of the job.

How can I achieve a mirror finish?

To achieve the desired finish, the part’s surface must first be properly prepared. In some cases, parts start with a very rough surface. Many parts require processing the surface with a series of abrasive belts and other abrasive products.

Mechanical Finishing Suppliers

Narrow by Mechanical Finishing Category

- Abrasive Belts, Discs

- Abrasive Blasting Equipment, Dry

- Abrasive Blasting Equipment, Glass Bead

- Abrasive Blasting Equipment, Wet, Vapor

- Abrasive Blasting Materials

- Abrasive Grain

- Abrasives, Non-Woven Nylon

- Associations, Tradeshows & Professional Groups

- Backstand Idlers

- Balls & Shapes, Burnishing

- Barrel Lining Service

- Brushes, Cleaning & Polishing

- Buffing Compounds

- Buffing-Compound Applicators

- Buffs

- Burnishing Compounds

- Centrifugal Barrel or Disk Finishing Equipment

- Chemical-Polishing Processes

- Computer Control Systems for Finishing Processes

- Computer Software for Finishers

- Consultants, Independent, Buffing/Polishing

- Consultants, Independent, Mass Finishing

- Contact Wheels, Abrasive Belt

- Conveyor Belts

- Conveyor Cleaning Equipment

- Conveyor Loading/Unloading Equipment, Automatic

- Conveyor Lubricators

- Conveyors, Chain-on-Edge Spindle-type

- Conveyors, Belt

- Conveyors, Flat Pallet

- Conveyors, Inverted Power-and-Free

- Conveyors, Magnetic Belt

- Conveyors, Overhead Chain

- Conveyors, Overhead Power-and-Free

- Conveyors, Wicket

- Conveyors, Overhead Traveling Hoist

- Courses in Vibratory Finishing

- Deburring Equipment

- Deburring Equipment, Abrasive Flow

- Deburring Equipment, Processes, Electrochemical

- Deburring Equipment, Thermal

- Deburring Services

- Dryers, Vibratory

- Electropolishing Equipment

- Equipment Engineering & Installation Services

- Electropolishing Solutions

- Felt Wheels & Bobs

- Flapwheels

- Glass Beads

- Gloves, Work

- Inks, Metal Color-Coding

- Inks, Metal Decorating

- Lapping Supplies

- Lathes, Buffing & Polishing

- Lime, Burnishing & Polishing

- Lining Services for Tanks & Mass-Finishing Equipment

- Lubricants, Dry-Film or Solid-Film

- Lubricants, Polishing

- Mass-Finishing Compounds

- Mass-Finishing Media

- Mass-Finishing Supplies

- Noise-Control Enclosures, Devices

- Nozzles, Abrasive Blasting

- Polishing & Buffing Equipment, Automatic

- Polishing & Buffing Equipment, Hand-Held

- Polishing Machinery, Abrasive Belt

- Polishing Wheel Cement, Glue

- Polishing Wheels

- Robots, Deburring, Buffing, Polishing

- Rubbing Compounds

- Safety Equipment & Materials, Personal

- Safety Storage Buildings, Enclosures

- Sanders, Hand-Held

- Shot-Peening Equipment & Supplies

- Spindle Finishing Equipment

- Used Equipment

- Vibratory Finishing Equipment