Controlling Temperature in Paint Process

Mike Bonner of Saint Clair Systems discusses using a temperature hierarchy to assess how to best control temperature in your paint process.

#ask the expert

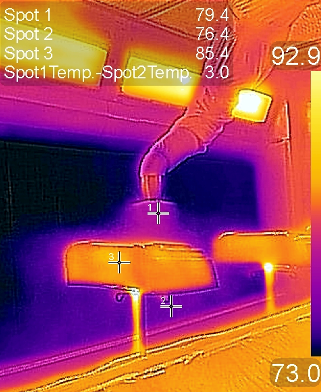

Figure 1: In 2018, Saint Clair Systems studied droplet temperature as a function of ambient air temperature, determining that droplets are not normally airborne for enough time to change temperature significantly.

Photo Credit: Saint Clair Systems

Q: I hear a lot about controlling temperature in my paint process, but what is the right temperature for my paint?

A: The real question here is what are the right “temperatures” to control? Though extremely important, it’s not just about the paint. In any manufacturing process — but especially in dispensing processes — there are many temperatures to be considered, and each one requires a different approach to control. But there are time constraints and budget limitations and, of course, everyone wants to get the “biggest bang for their buck,” so it is important to know where to focus your energies, and dollars, to produce the best result.

Featured Content

Our research has shown that the order of importance for impact on the outcome of most paint processes is:

- Substrate temperature

- Fluid temperature

- Ambient temperature

We call this the “Temperature Hierarchy.”

As it turns out, this is also the order of difficulty from hardest (and most expensive to control), to easiest. The fundamental reason is mass — thermal mass, that is…

The substrate is the most important because it has the greatest thermal mass of the three. Even small parts will have orders of magnitude greater mass than the paint being applied to them. This influences the paint as soon as it hits the surface.

If the substrate is too warm, it can cause the viscosity of the paint to decrease suddenly, causing it to flow in ways we don’t want it to, which can result in runs and sags, or pulling away from sharp corners leaving them unprotected. Or it can cause the paint to cure prematurely, by driving off solvent too quickly or accelerating the 2K curing rate, stopping the paint from flowing out properly, resulting in gloss and orange peel issues, for instance. By the same token, if the substrate is too cold, it can cause the viscosity of the paint to increase suddenly and also prevent it from flowing out the way we need it to. And that’s the rub — improper substrate temperature can produce the same defects whether it is too warm or too cold making its impact very difficult to analyze.

The final point here is that substrate is the most difficult to control. The greater the mass of an object, the more energy is required to change its temperature. Since we all know that energy costs money, substrate temperature control costs the most to design, install and operate.

Next is paint temperature. The key point here is viscosity. Temperature inversely affects paint viscosity. As the temperature increases, the viscosity decreases. Conversely, as the temperature falls, the viscosity increases. This temperature-based change in viscosity affects things like flow out, run and sag, orange peel, and gloss, just to name a few. Maintaining a stable and consistent paint temperature assures a stable and consistent viscosity — a major factor in paint process outcomes. It is also easier and more economical to control than substrate temperature. But if it is just going to change when it hits the substrate, why bother?

The reason is that it is important to control all of the variables that we can in our process. If we control the temperature, and therefore the viscosity of our paint so that its viscosity is always constant, we can check that off the list when we are analyzing an issue. Moreover, we can adjust the viscosity by shifting the temperature of the paint to compensate for other issues. It changes viscosity from a variable, to a constant, and then to a tool we can use to control our process.

Which brings us to air temperature. It’s a topic we all understand. Regardless of where we live, we likely have furnaces and/or air conditioners in our homes to control our environment to keep us comfortable. This intimate understanding makes it easy to justify our efforts and energy. In fact, paint shops spend millions of dollars each year to control the ambient environment in their booths — and often in their mix rooms. The logic seems simple. When the paint is atomized, the tiny droplets have lots of surface area exposed to ambient and the prevailing logic is that the droplets will be at ambient temperature by the time they make it to the part. Thus, when we control air temperature, we also control our paint temperature.

But the reality is quite different.

In 2018, we studied droplet temperature as a function of ambient air temperature. And as it turns out, the droplets are only in the air for 0.5 – 1.5 seconds, which is not enough time for them to change temperature significantly. In fact, we calculated that even for a 13°F temperature differential between the paint temperature and the ambient temperature, the change in droplet temperature between the atomizer and the part would only be 0.25°F – 2.5°F. When we shot the process with a thermal camera, as shown in Figure 1, the picture clearly shows that even the particles in the cloud that have traveled past the part are still within 3.0°F of the temperature of the paint exiting the bell (Spot 1 – Spot 2).

So, to answer your question, the “right” temperature for your paint is the one that produces the best outcome in your process. And it may be different for different types of paint or for different processes — so even two different facilities within the same company using the same paint from the same supplier may require a different paint temperature to produce the desired outcomes from their processes. And that’s the reason that having the ability to control paint temperature is so important.

RELATED CONTENT

-

Automate Your Brush Plating Operation

Derek Kilgore from Sifco ASC says the brush plating operation can be mechanized, semi-automated or even fully automated.

-

Coating Systems with the Best Long-Term Performance

The best protection against corrosion and UV exposure, says Axalta’s Mike Withers, is electrocoat and a super durable powder coating.

-

Plating with Zinc-Nickel: Benefits and Challenges

Chad Murphy of Columbia Chemical speaks about the benefits of various types of zinc-nickel alloy, and provides tips for manufacturers about the zinc-nickel plating process.