For more than 35 years, ProPlate has been offering custom plating solutions to businesses in the greater Twin Cities region in Minnesota. Current owners Craig and Suzanne Ingalls bought the company in the late 1990s, and about 10 years ago, saw the opportunity to focus on medical devices. Historically, platers and medical devices have not always played well together, specifically for coating electrodes for diagnostic medical procedures. Because of that, manufacturers tend to work with subtractive manufacturing, or trying to cut metal for their parts, missing the opportunities that plating offers for more complicated shapes and using precious metals like gold and platinum. But ProPlate has worked to optimize its plating operations, even patenting some of them, and found that partnering with its OEM customers from the initial design of the product makes for a better overall outcome for both parties.

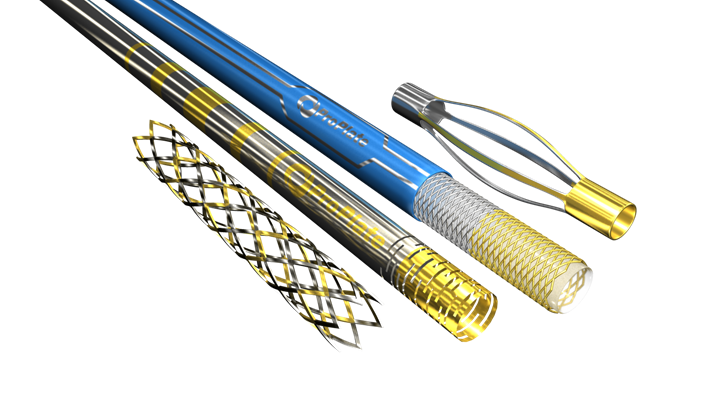

Stents and catheter components often have unique geometries that make them difficult or impossible to machine, making plating a great solution.

Photo Credit: ProPlate

The team at ProPlate recognized that the industrial plating world can be cyclical, but also inconsistent and hard to predict. The company looked at its strengths and decided to focus on medical device plating and built a niche business into a successful enterprise today. To get there, ProPlate hired experienced outside medical device reps to help build the business. Today, the core values of the company align with a higher purpose to use all the tools in its proverbial toolbox to provide solutions for its customers.

Featured Content

The origin story

“Traditionally, electrodes used on medical testing apparatus have been made with alloys and are machined tubes, and there’s not a lot you can do to innovate,” says Ross Peterson, VP of business development for ProPlate. “There are design constraints due to wall thickness for subtractive processes and traditional machining. We turned it around and created our Vizi-Band process, which uses the additive technology of plating to apply pure platinum or pure gold directly onto a device.

“Vizi-Band is a proprietary metal coating process that atomically bonds directly to a catheter, guidewire, stent or similar component. The highly radiopaque and biocompatible metal coating can be selectively applied to any section of the desired component, with endless options for customization depending on the application and intended use.”

Many markers a remade with polymers that are loaded with radiopaque materials, but these have a limited shelf life since polymers are not inert materials, making metal a better option. But there can be a differential, which Peterson says depends on the application and design requirements.

“Sometimes we are more expensive, but you get a performance aspect you can’t get from other products. With traditional markers that are swaged or crimped onto the tubing, a lot of the materials are absorbed into the tubing and won’t show up under fluoroscopy. Feedback on the plated markers is that they perform well and show up on imaging as bright or brighter than traditionally manufactured markers.”

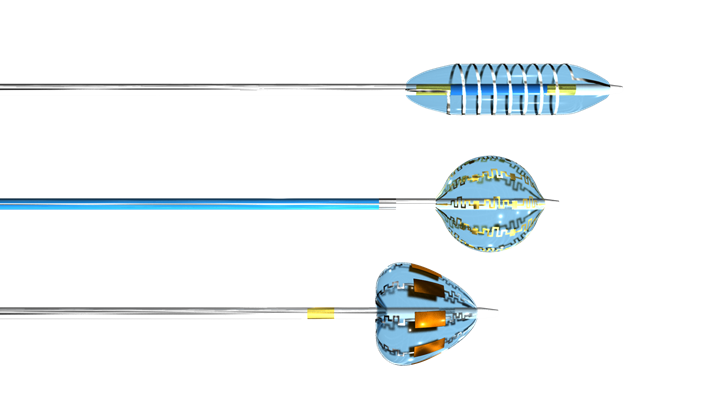

Catheter components and balloons with Vizi-Band and Meta-Poly technology from ProPlate.

Photo Credit: ProPlate

Peterson says ProPlate’s customers find a lot of upsides for performance using plating. They can place the metal markers in places that would be difficult or impossible to do with other manufacturing processes and create new and different shapes to allow not just the location of these markers to be seen, but also the orientation of them under fluoroscopy. This allows the medical professionals who administer these tests to glean information they couldn’t get before now.

ProPlate says it can often save its customers money because it can plate with less precious metal than a traditional marker would be made from, but still provide adequate or better performance. What started as one idea to try has snowballed for the company and they are working with customers to develop even more innovations, from stents to catheters. And they have the quality certifications to back up their work.

Collaboration leads to innovation

One opportunity came to ProPlate from the University of California San Francisco’s surgical innovations program. The team at UCSF had received approval for a compassionate use medical device for infants. The team was using rare earth magnets made from neodymium iron boron (NdFeB) in a variety of medical devices but found the instruments challenging to work with because the magnets are so strong that they could harm the patient or the care team if not encased properly. Products like these are produced in other parts of the world, but none have lived up to the stringent requirements to pass FDA trials for biocompatibility.

The specific device they worked on together was to treat children born with a debilitating congenital malformation where a child’s esophagus doesn’t develop properly or attach properly to the stomach. While one in 3,000 children are born with some level of this condition, there isn’t much work being done to innovate the very invasive surgery needed to fix this malformation. Today it requires a significant incision across most of the child’s chest and abdomen. As with any surgery, particularly on a newborn, there can be issues and complications with the procedure that require subsequent surgeries.

Rare earth mineral magnets are hermetically sealed in solid gold via plating for medical interventions.

Photo Credit: ProPlate

While magnets have been used in this procedure before, it is still a challenging application because the magnets are placed inside the gastrointestinal tract — an extremely corrosive environment that is also ever-changing. Given the patients are infants, the size of the device must also be very small — only a few millimeters. ProPlate has developed advanced electroplating methods that are optimized for these materials and for implanting in the body. Through this collaboration, a new category of devices was invented that use magnetic force and “precision-engineered tissue-contacting surface architectures” to fix these malformations with much less invasive procedures.

Peterson explained that the magnets are manufactured with a sintering process that leaves them very porous. ProPlate’s challenge was to completely encase and hermetically seal these magnets while providing corrosion resistance for implantation, all while increasing mechanical strength to reinforce the fragile magnets. It took the team a lot of trial and error, but they learned a lot and came up with a winning solution. The company developed a multilayer plating process that offers mechanical and chemical integrity to the devices that protects them from forces encountered during surgical placement and handling of the magnets. The team at UCSF said that with this positive experience and all the learnings from it, they see “endless opportunity for growth in the medical field.”

ProPlate continues to look for new ways to solve problems for its customers. The company has received a number of patents for its innovative technologies, including metallizing of polymers and for Vizi-Band, braided catheter technology and a torque lock technology it developed.

When asked about competitors, Peterson says there’s not a lot of direct competition today because it is such a niche business, “but we welcome it because it validates our technology. We’re not focused on our competition; we’re focused on our customers.” That philosophy is what makes ProPlate an outstanding partner to its clients.

RELATED CONTENT

-

Electroplating for Medical Devices

Brittany McKinney of Pavco Inc. discusses the benefits of electroplating for medical devices.

-

Solving Unmet Needs of the Medical Device Industry

Pioneer Metal Finishing's Medical Center of Excellence has expanded the company's capacity to serve the critical medical device industry. With ISO 13485 certification in hand, the company is now a key driver in medical innovations.

-

Plating Additively Manufactured Plastic Parts

Using electroplating to enhance the structural properties of 3D printed parts.