Dubois Chemicals Showcases Its Bright, Electroless Nickel Alloy

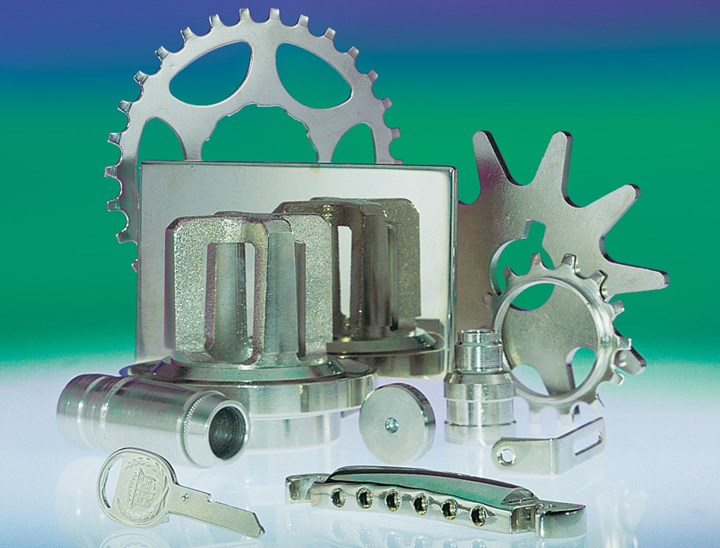

SUR/FIN exhibitor DuBois Chemicals’ Nitec Viro-Brite deposits a bright, uniform nickel-phosphorous alloy over steel, stainless steel, aluminum and copper alloys.

#surfin

Dubois Chemicals will showcase Nitec Viro-Brite, a cadmium and lead-free electroless nickel process. Viro-Brite, which is restriction of hazardous substances (ROHS) compliant, deposits a uniform nickel-phosphorus alloy over a wide variety of substrates, including steel, stainless steel, aluminum and copper alloys. According to the company, Viro-Brite produces exceptionally bright coatings that remain bright throughout the life of the bath. Viro-Brite’s operational benefits reportedly include excellent bath stability, consistent deposition rates, high tolerance to metallic impurities and long bath life.

Dubois Chemicals | 413-452-2000 | duboischemicals.com

RELATED CONTENT

-

Is Your Electroplating Waste Hazardous?

Some that bears precious metals is, and there are a host of regulations to consider when recycling.

-

Curing Oven Basics

Simply heating up the substrate does not cure the coating. There are many variables to consider when choosing the best cure oven for your application...

-

Masking for Surface Finishing

Masking is employed in most any metal finishing operation where only a specifically defined area of the surface of a part must be exposed to a process. Conversely, masking may be employed on a surface where treatment is either not required or must be avoided. This article covers the many aspects of masking for metal finishing, including applications, methods and the various types of masking employed.