Dürr recently built a high-tech paint shop for Ford Motor Company in Hermosillo, Mexico. The new shop, which supports the production of a new Ford vehicle, uses modern technology, digital solutions and local climate conditions to attain high painting quality.

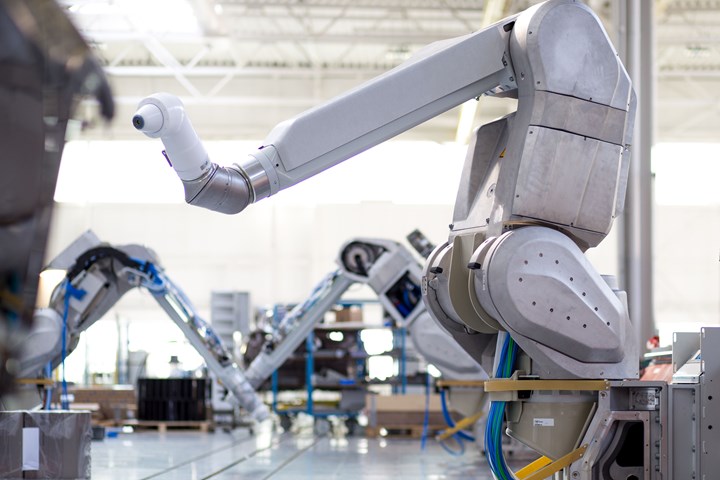

The new paint shop includes low and high viscosity material supply systems, robotic paint and sealer application equipment and other process automation technology. In addition to using two painting booths for a three-wet process, Ford uses a dedicated booth for two-tone painting via masking. Dürr says that arranging the two-tone coating separately creates flexibility and ensures the highest efficiency of the coating line.

Featured Content

Dürr’s EcoRP E033i painting robots perform the automatic exterior coating of primer, base and clear coat in all painting booths. Dürr’s EcoRP S153i swingarm robots then base-coat the interior cargo areas. With its highly mobile swingarm, the robot can apparently reach surfaces several meters away, as well as hard-to-reach areas in the interior. According to Dürr, the modularity of these robots, which were designed specifically to paint commercial vehicles, allows for high flexibility and improved robustness. For the two three-wet topcoat painting booths, Ford opted for the EcoEnvirojet wet scrubber technology.

Taking advantage of the heat

One distinctive detail of the plant is that it takes advantage of Hermosillo’s high temperatures and dry weather during most of the year. The e-coat, sealing, two-tone and topcoat Ecopaint ovens are installed outside and use the high ambient air temperature for energy efficient heating. The ovens are equipped with Dürr’s recuperative thermal oxidizer Oxi.X TR, an elimination system for volatile organic compounds that, according to the company, is the most efficient, cost-effective method of air purification. The modular ovens are located outside in a U-turn layout so the car bodies can leave the building, go through the ovens and then return indoors.

Increasing transparency through digital solutions

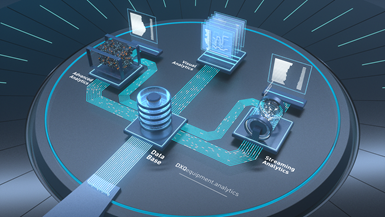

Dürr's scope of supply also includes the digital solutions DXQplant.monitoring and DXQequipment.analytics, which reportedly provide greater visibility of factory and equipment data while achieving significant downtime reduction. The analysis software, DXQequipment.analytics, evaluates all robot and process data down to the millisecond, enabling operators to quickly identify and rectify faults. The system also includes a streaming analytics application for real-time data analysis.

Establishing modularity and automation

Dürr also installed phosphate and electro dipcoating tanks equipped with Ecopaint PT/EC pendulum system, as well as the modular anode control EcoDC MACS. Dürr says the modular design of this anode control protects the system from failures. Due to multiple rectifiers, the system enables an individual setting of voltage for each car body type.

The sealing line includes manual and automated zones. Four EcoRS 30 L16 sealing robots and two EcoRS 16 overhead handling robots are installed in the liquid-applied sound deadener zone, while the underbody sealing zone is equipped with two EcoRS 16s. Dürr says the robots ensure a safe, reliable performance through strategically located sensors that help to avoid errors and collisions.

According to Dürr, the creation of the new paint shop represents the largest order that Ford has given to the company in Mexico. “We are proud that Ford has given us the opportunity to realize highly efficient concepts, and cutting-edge technologies from Dürr,” states Sandro Picchio, CEO of Dürr Mexico. “We support Ford’s production process with the highest quality standards, the most cost-effective units and lowest environmental impact.”

RELATED CONTENT

-

Dürr Partnership Expands Market Access for EV Batteries

The Dürr Group and Osaka-based firm Techno Smart have partnered to increase EV battery production efficiency. The Dürr Group is also expanding its small-factor battery production tech business and contributing to EV production across multiple departments.

-

Evolving Automation in Automotive

A look at the latest liquid coating technologies for the automotive sector from leading robotics and surface finishing technology providers

-

Building an E-coat Line from the Ground Up

How one company is prospering by providing flexible e-coat capability to Nissan and other customers.