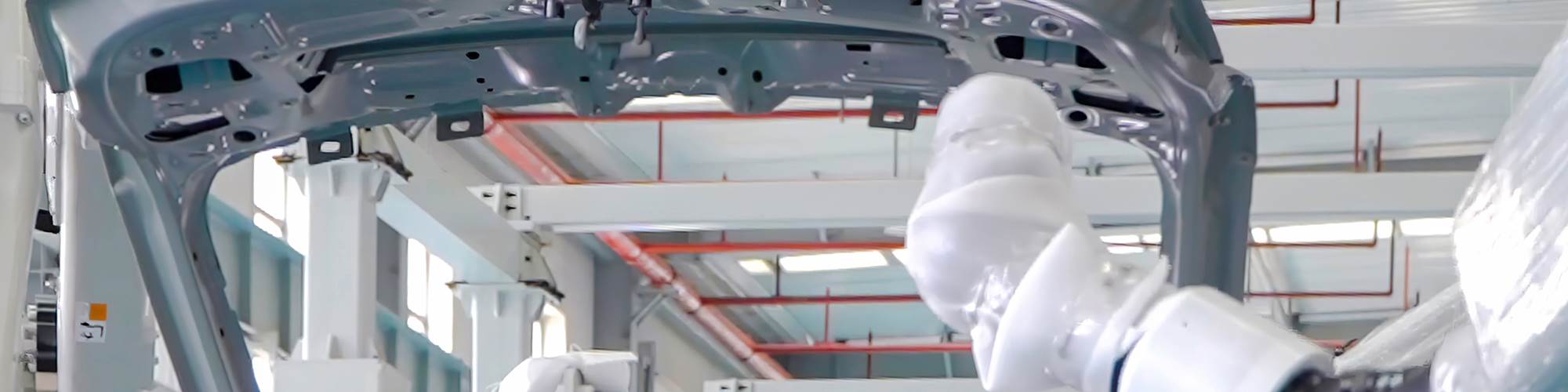

ABB Robotics recently unveiled its Compact Interior Paint Station, which offers a space-saving alternative to traditional robotic interior painting systems.

Photo Credit: ABB Robotics

Industrial robots are nothing new for the automotive industry and have been used to paint vehicles for decades. However, as time marches on, so too does innovation. Much has changed and the hydraulic paint robots that first mechanized automotive production lines now seem low-tech in comparison to the latest technologies. Robotic advancements have allowed automation solutions to enter other areas of the automotive supply chain as productivity gains, efficiency improvements and waste reductions have made them viable for tier suppliers. Once reserved for large OEMs, robots are now employed in the paint lines of most top tier shops — and innovations in automation show no sign of slowing down.

Matt Sikowski is the director of the Paintshop Process and Application Technical Group at FANUC America, a leading supplier of robots, CNC systems and factory automation. From its P-250 pedestal robot to its P-700 rail-based model to its P-1000 7-axis pedestal robot enabling interior and exterior paint application, FANUC America has a full range of painting and coating robots designed for a variety of applications and for a wide range of reaches and handling capacities. “Sustainability is a focus that many of our customers have been looking at and continue to investigate,” Sikowski says. “Another common trend throughout time has always been trying to automate difficult and very repetitive processes within the automotive paint shop.”

Featured Content

FANUC P-500 robots on an automotive paint line. Photo Credit: FANUC America

The use of robots allows for recirculation of booth air and reduction in downdraft velocity. The lower ventilation velocities help enable specialized atomization methods used to coat complex geometries, including auto body interiors, engine boxes and door jams. As automation technologies have evolved to become more compact and adaptable, they have become an integral part of the automotive industry — an industry that demands flexibility along with the ability to scale. The variety of models on which manufacturers work is constantly growing and their production methods must afford them flexibility.

Sikowski points out that tier suppliers often have contracts with two or three OEMs. “It requires a lot of flexibility within the automotive package to be able to paint those different colors and the different parts for their different customers,” he says.

Advances in automotive finishing are driven by the need for constant improvements in the repeatability of finish quality and the ability to accommodate changes in vehicle models, as well as on improving efficiencies, increasing safety, reducing waste and lowering energy consumption. Automation is key to enabling all of these goals, allowing for increased productivity, more repeatable and controllable processes, and energy savings by way of reducing spray booth ventilation requirements. Several solutions from leading robotics and surface finishing technology providers announced during the past year have been aimed at offering automotive manufacturers improved efficiencies, flexibility and sustainability.

A modular approach

Dürr’s EcoProBooth features a unique box layout that allows for the flexibility to accommodate a mix of vehicle models.

Photo Credit: Dürr

Dürr (Southfield, Mich.) recently unveiled its “paint shop of the future” concept, featuring the new EcoProBooth paint booth. The booth utilizes a unique box layout that allows for the flexibility to adapt the line based on the growing variety of vehicle models produced by automotive manufacturers. The booth’s modular concept enables conversions and extensions to accommodate changing production needs.

The EcoProBooth can accommodate a mix of vehicle models, from compact cars to medium-sized SUVs. It combines interior and exterior painting processes into a single workstation, using up to eight painting robots and four SCARA robots for opening doors. The box layout also helps reduce material consumption due to smaller losses when changing color. Dividing the line into shorter sections makes it possible to distribute the painting jobs so color changes are minimized.

In addition, the booth allows for routine maintenance and cleaning without interrupting production. Service cubicles at each corner of the paint booth allow technicians to clean or replace application technology without having to enter the application area in the paint booth. If a robot requires maintenance, it reaches its arm through a window into the service area. The cubicles are continually flushed with fresh air, providing safe workplaces. Meanwhile, the application area of the EcoProBooth maximizes air recirculation to reduce energy consumption and CO2 emissions.

Overall, Dürr’s modular booth concept checks off several of the automation boxes. It increases efficiency with less maintenance downtime, reduces energy consumption and VOC emissions, and improves production by combining interior and exterior painting in a single workstation.

Saving space

ABB’s Compact Interior Paint Station reduces the number of required robots and eliminates the need for a linear track.

Photo Credit: ABB Robotics

Over the years, global technology company ABB Robotics (Zurich, Switzerland; Cary, N.C.) has made numerous contributions to high-performance liquid coatings. In 2020, the company launched a number of new technologies to support manufacturers working in the automotive sector. In November, ABB unveiled its Compact Interior Paint Station, which offers a space-saving alternative to traditional robotic interior painting systems. The solution reportedly allows OEMs to reduce the footprint of their paint booths by up to 33 percent and is designed to process a variety of vehicle types, including cars, sports utility vehicles and multi-purpose vehicles.

The paint station employs six ABB IRB 5500-27 7-axis robots as well as four IRB 5350 door-opener robots and two IRB 5500-22 robots to open the hood and trunk. The IRB 5500-27 boasts a 3.8-meter working envelope, offering extended reach and an enhanced working angle with a choice of floor, wall or inverted mounting options. According to ABB, the improved reach allows the robot to optimize the angle of the atomizer in relation to the substrate, minimizing overspray and waste. The company says that the enhanced working angle reduces the number of required robots and eliminates the need for a linear track.

“By removing the need for ancillary equipment, such as the linear track and additional ventilators, the Compact Interior Painting Station can help to significantly reduce the time and cost of setting up a paint booth,” says Jörg Reger, head of robotics and automation for ABB Robotics. “With its ability to fit into different booth configurations, and with fewer items that need to be installed and maintained, it presents an ideal solution for retrofitting existing paint shops.”

In addition, ABB’s robots are able to compensate for one another in the event of a failure, increasing speed or cycle time until the failed unit can be brought back online. Collision prevention software is used to coordinate the work of the robots and ensure worker safety.

Reducing waste

ABB’s PixelPaint overspray-free technology is available as a cell using two ABB IRB 5500 robots.

Photo Credit: ABB Robotics

The desire for more versatility and also waste reduction has led to another recent trend — overspray-free technologies.

ABB recently unveiled PixelPaint, a technology that uses an inkjet head in place of a traditional spray approach. The solution is said to improve automotive painting speed and reduce waste. The inkjet head eliminates overspray by printing paint directly onto a target area, resulting in 100% transfer efficiency. The solution allows for two-tone paint and individual designs in one pass without the need for masking. According to the company, the solution reduces downtime, improves productivity and allows for more customized paint scheme options.

“With PixelPaint, 100 percent of the paint is applied to the bodywork surface, so there’s no overspray,” says Michael Larsson, group senior vice president and managing director automotive OEM for ABB Robotics. “Not only does this reduce operating costs and improve environmental performance by ensuring that no paint is lost, PixelPaint also eliminates the process of masking and de-masking each car, helping to reduce bottlenecks in automotive paint shops.”

The solution is available as a cell using two ABB IRB 5500 robots.

Dürr’s EcoPaintJet uses 50 capillary nozzles that produce parallel paint jets that can be activated or deactivated to enable quick color changes.

Photo Credit: Dürr

Dürr also has an overspray-free technology that has been on the market for about a year. The company’s EcoPaintJet works without an atomizer and can apply paint over large areas or in simple patterns with high edge definition without any overspray. The solution controls paint supply using three valves and its applicator boasts a nozzle plate with around 50 capillary nozzles that produce parallel paint jets which can be activated or deactivated to enable quick color changes. The width of the painting path can be adjusted via the applicator’s angle of application or by adapting the nozzle plate. Coating thickness is controlled via the applicator speed and solid content of the paint.

“The overspray-free application set enables application with high edge definition, fast color changes, and a custom surface design,” says Holger Beiersdorfer, vice president industrial products at Dürr.

While the application was first used in the automotive sector, the technology is available for integration into general industry applications.

What’s next?

At the heart of all these improvements is the same thing that drives all business — competition. As increasing numbers of models enter the market, including hybrids and electric vehicles (EVs), OEMs are looking at myriad ways to make their vehicles stand out. Sikowski thinks EVs are helping to drive some of the innovation. “If you look at like the electric vehicle market, there are a lot of different things that are being evaluated within the painting trends. We’ve had customers that are coming out with some very unique and special colors,” he says. “They’re even looking at changing the way that they paint the vehicle.” The two aforementioned overspray-free technologies are a good example of this.

Of course, any new innovation will lead to subsequent adaptations and new ideas. As they say, the wheel keeps on turning.

RELATED CONTENT

-

Let’s Finish Closing the Quoting Gap

Sharing accurate, timely and actionable data is the key to an effective, respectful relationship between a finishing shop and a contracting machine shop. Software that streamlines the quoting process can make this happen.

-

SIFCO ASC Reduced Selective Plating Costs with Automation

SIFCO ASC’s automated selective plating workstation not only improved the surface quality of finished products, it reduced process times by 90% and saved Powell Electrical Systems around $100,000 annually.

-

Robotic Process Development for Finishers

Norton | Saint-Gobain’s new Abrasive Process Solutions (APS) lab offers path to automation for mechanical finishing processes.