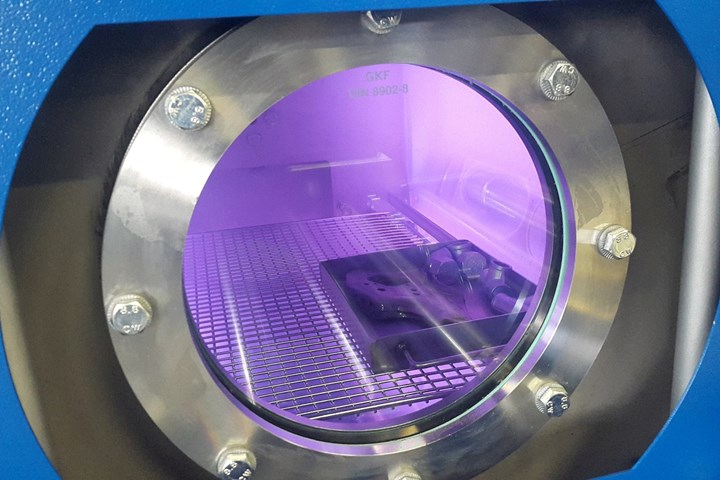

According to Ecoclean, by combining wet chemical and low-pressure plasma cleaning methods for ultrafine degreasing in a single machine, the surface characteristics required for downstream coating or bonding are efficiently achieved. Photo Credit: SBS Ecoclean Group.

Due to changes in manufacturing, joining and coating technologies, as well as more stringent regulatory specifications, there are increasingly strict requirements for particulate and film-type part cleanliness. Whether it be production equipment for the semi-inductor industry, biotechnology, laser and sensor technology, devices for measuring and analysis technology or components for accumulators, fuel cells and optical systems, the requirements for performance and reliability are extremely high, which necessitates improvements to cleanliness processes. Additionally, for medical technology products such as implants, instruments, cannulae and endoscopes, particulate and film-type contamination from manufacturing processes is an essential criterion due to regulatory specifications. Moreover, there is also a trend for miniaturization and functional integration with smaller and more complex components.

According to SBS Ecoclean Group (Frankfurt, Germany), a supplier of complete cleaning solutions, these developments entail that particulate cleanliness specifications in the micrometer and nanometer ranges, as well as very stringent requirements regarding residual thin-film contamination, must be met by more and more industry sectors. Depending on the components and/or applications, outgassing rates for organic substances and residual moisture may also have to be met, as well as limit values reduced down to the atomic percent range in surface analyses for residues of prohibited substances.

Featured Content

For Ecoclean, the result is a series of very demanding parts cleaning tasks across the complete manufacturing chain. Ecoclean says it adapts its cleaning processes, control software, machinery and ambient conditions to evolving requirements and applications.

Choosing the right system concept

For integration into clean rooms the ultrasonic ultrafine cleaning systems are fitted out in compliance with the applicable clean room class. Photo Credit: UCM / Gebr. Brasseler

When selecting a suitable cleaning system for a specific task, Ecoclean first determines whether the system will be used for pre-cleaning, intermediate cleaning or final cleaning. Depending on the use and cleanliness specifications to be achieved, the solution may be chamber or multi-tank immersion machine, a flexible ultrasonic multitank machine based on standardized modules or a customized ulrasonics-based ultrafine cleaning system. The cleaning chemicals and optimal process technologies (for example, spraying, high-pressure fluid application, immersion, ultrasonic or megasonic treatment, plasma cleaning, injection flood wash, pulsated pressure cleaning (PPC), as well as passivation/preservation as required) are also specifically chosen for the application and the contaminants to be eliminated.

Cleaning processes and systems for ultra-high cleanliness

Standard equipment installed in precision and ultrafine cleaning systems are multifrequency ultrasonic systems that offer flexible adjustment of ultrasonic frequency and intensity to the requirements of different parts to be cleaned. With parts that present complex geometries, capillary structures or porous surfaces, such as sintered metal components or additive manufactured components, the PPC method comes into play. Features such as multi-side overflow in all wash and rinse tanks, as well as the immersion/spray rinse technology specially developed for ultrafine cleaning systems, are designed to help meet cleanliness specifications.

In the immersion/spray rinse tanks specifically developed for ultrafine cleaning processes, the parts are sprayed off as they exit the bath. This is said to enhance the rinsing result. Photo Credit: Zeiss.

According to Ecoclean, the decision of which parts are taken to which wash and rinse tanks, as well part-specific process parameters such as temperatures, ultrasonic output and frequency, intensity of PPC and dwell time in the various wash and rinse tanks, are defined during the process development phase. Depending on the complexity and heat absorption capacity of the parts, drying is mostly done using infrared or vacuum technology. The resulting part-specific cleaning programs are stored in the machine controller. Ecoclean says the software-controlled implementation of the cleaning sequence plays a decisive role in this context, as it ensures that the specified dwell times in wash and rinse tanks are precisely observed, and that prioritized sequences (for very fragile parts, for example) can be programmed.

Through cleaning trials using original parts in its facilities, Ecoclean says it can help determine the best system and process solution for cleanliness and economic efficiency.

RELATED CONTENT

-

The Hull Cell: Key to Better Electroplating - Part II

How to use it for planning, preventive maintenance and troubleshooting.

-

Stripping of Plated Finishes

The processes, chemicals and equipment, plus control and troubleshooting.

-

Cleaning Limescale from Galvanized Steel

How do you clean white lime scale and rust spots on galvanize?