Four Supplier Resources to Get More Out of Your Surface Finishing System

Get the most out of your paint and powder coating line by taking advantage of a few resources that can not only optimize your systems but ensure max productivity from installation and long after.

Whether it’s a sparkling new system or a long-time member of the factory floor, the goal of any surface finisher is maximize production. That means not only optimizing your equipment for peak performance but also preventing any unnecessary downtime. For applications such as E-coat, liquid spray or powder coating, this means setting up good habits and planning early on. Unfortunately, many distributors or system integrators only aid the beginning of the process: system design, fabrication, and installation, and don’t provide ongoing support and service.

With Therma-Tron-X (TTX), leading provider for custom paint finishing systems, customers can count on the support needed to maximize production and maintain uptime with experienced, skilled service and readily available spare parts.

When it comes to unplanned downtime, the time to act and respond is not in the moments as a piece of equipment fails. That’s why it’s important to discuss options for how to resolve equipment failures before they happen. For any new piece of equipment, start by asking a few questions

- What kind of system do I have and what kind of parts does it need?

- What kind of common equipment issues can I expect overtime?

- What kind of obstacles or issues should I be looking for?

- What kind of issues should I be prepared to handle on my own?

- When should I get help from my supplier or other maintenance services?

Knowing what to expect is the first step in being prepared for common equipment failures, and this also helps you to predict and avoid costly downtime. For the times when you need a little extra help addressing equipment issues, here are 4 examples of how Therma-Tron-X helps customers get the most out of their system.

- Maintenance and Inspection

- Spare Parts Inventory

- Digital Tools and Communication

- Quick Onsite Services

1. Maintenance and Inspection

Maintenance is single handedly the most important part of getting the most out of any piece of equipment. Unfortunately, too often it’s misunderstood and can end up being the largest hidden cost for the entire operation. Understanding the power of maintenance starts with tackling a few misconceptions.

Equipment Maintenance Myths

- “I thought it was supposed to do that.”

- “Maintenance Manual? There’s a manual?”

- “Maintenance is just recommended not required.”

- “It’s just not a priority around here.”

- “We don’t have time.”

- “We don’t have the resources”

- “We’ll do it later when it gets more serious.”

Predictive maintenance, specifically, is too often considered an unnecessary practice for new equipment, something you don’t need until down the road. In reality, one of the best times to set your equipment up for future maintenance is right after it’s installed. This is a great opportunity to get even more familiar with the system and all of its components. It’s a chance to run tests while integrating the system into your facility. During this step, TTX engineers are available onsite to help get systems up and running quickly and smoothly. These engineers train personnel as well as help do initial troubleshooting.

Top Benefits of Preventative Maintenance

- Minimize equipment failure

- Avoid costly repairs

- Preserve and restore equipment

- Extend lifespan of equipment

Preventative Action

- Perform tests

- Record measurements

- Make adjustments

- Identify part replacements

- Regular cleaning

To get an example of a preventative maintenance schedule, click here.

Emergency repairs not only disrupt production runs, but cost on average 3 to 9 times more than planned repairs. This includes costs for expedited shipping and teams working overtime. While initially saving money on maintenance, using this method of “reactive maintenance”, or maintenance only when something breaks, can lead to costly and unpredictable collateral damage in the long run.

Instead, it’s important to discuss early on what kind of inspections your equipment needs, and how often. Prior to getting equipment up and running, make sure to ask questions like:

- What kind of routine checks do I need?

- How often should I schedule inspections?

- When should I include onsite inspection with a supplier or equipment manufacturer?

2. Spare Parts Inventory

One of the most important contributing factors to machine downtime is the natural wear and tear of system components. An important step in keeping downtime minimal is making sure you have an updated Spare Parts List and are prepared to replace any parts that can threaten to shut an entire finishing system down.

Consider first whether to stock complete replacement components or repair items. Factors in deciding which to stock will include whether the component is critical to the operation of the equipment, how readily accessible are replacement components, and how easy is it to disassemble and repair components.

With TTX, customer service representatives are heavily involved in the process of setting up spare parts lists, establishing schedules for ordering inventory as well as offering tips on part replacement and installment. TTX engineers can let customers know exactly what parts they need to keep on hand and what they can order through TTX directly.

Spare Parts Questions to Ask Your Supplier

- Which components are essential?

- Which parts are hardest to access?

- Which parts need to be replaced most frequently?

- What kind of part replacement requires shutting down the system? And for how long?

- How many replacement parts should I have available?

3. Digital Tools and Communication

For any piece of major finishing equipment, it’s important that you don’t feel like you have to go it alone. Having easy access to your supplier for questions and concerns is essential to make sure you’re getting your money’s worth.

First Impressions: Face-to-Face Customer Service

At TTX, the customer service and spare parts team get introduced to the customer during the installation phase, just before start-up and testing. The team helps to put together the spare parts list and will handle warranty work if needed. TTX tries to make sure that this is a face-to-face introduction, as in many cases this is a connection that will last a lifetime.

There are times when performing service on the equipment should be done in conjunction with the manufacturer. Major equipment repairs can often go quicker and will provide more long-term reliability by including the manufacturer in the repair process. Some options include having TTX service reps complete the repairs as a turnkey service or having them provide a knowledgeable supervisor to work with plant maintenance personnel or local contractors to complete repairs.

Equipment Downtime Resolved Over-The-Phone

In other cases, a simple phone call can provide all the info you need. Looking for a quick answer, or maybe some quick reassurance related to maintenance. TTX service representatives are available to answer your calls 24/7.

Equipment concerns that have commonly been solved over-the-phone range from mundane to panic-inducing.

In one example, a customer with a Reverse Osmosis system was having issues with their units and didn’t know where to start. A TTX service technician was able to look at the customer’s log sheets for the unit and realize the membranes were overdue for cleaning. For another customer, their cure oven wasn’t starting. Over the phone, the service technician walked them through the electrical section of their maintenance schedule, checking each component to identify the problem.

Secure VPN Connection

For times when it may be too complicated to explain over the phone but doesn’t necessarily require an onsite visit, a VPN connection is a great resource.

If a customer chooses to do so, TTX can set up a VPN (virtual private network) connection, which establishes a secure connection to another network over the internet. From there, a service technician can log into the customer’s PLC (programmable logic controller) and see exactly what is going on with their system. They can then download a copy of their program, make the necessary changes to it, re-upload it and cycle it through the system to test the changes. The technicians can watch and see how the changes effected the system and make any further modifications.

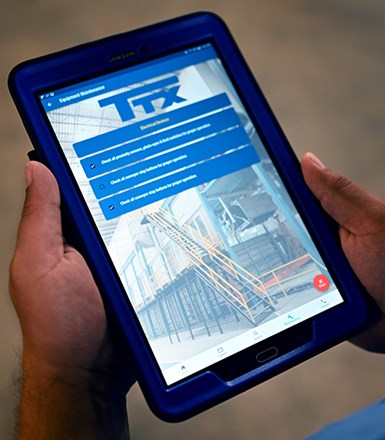

TTX MAPP Tablet and Tools

New this year, TTX offers its TTX MAPP resource, a tablet with built-in electronic documents and resources for customers, such as:

- System manuals

- Customer-released drawings and schematics

- Spare parts lists

- Searchable spare parts listings

The tablet also includes automatic email generation with picture-taking capability so customers can reach out to a technician with the exact info they need. Resources such as the digital manuals are updated live and are unique to each job.

4. Quick Onsite Services

Plenty of equipment problems can be addressed on the spot by reviewing system manuals or giving their system manufacturer a quick call or email. However, for the more complex, detrimental equipment failure, sometimes onsite assistance is the best and only option.

At TTX, all of the resources are used as a way to compliment the company’s dedication to hands on service, and that includes taking trips out to the facilities of the customers that need them. That’s why TTX service technicians sometimes spend nearly half of the year on the road, visiting facilities regularly and addressing immediate servicing needs. Their service departments can average one emergency request a week that requires a service rep to pack up and answer the call.

TTX’s full-service department is available to visit any customer in the U.S. and Canada using its own aircraft transportation, TTX Air, for onsite support. They also have personnel based locally in Mexico dedicated to Mexico-based facilities.

Regardless of the application, a systems output is only as powerful as the attention it is given, from day 1 through the lifetime of the system. To make sure you’re getting the most out of it, it’s crucial to get to know your equipment, know your spare parts list and know your service department.

To learn more about Therma-Tron-X, click here.

MEET THE TEAM

The Therma-Tron-X service department team is ready to meet you and answer all of your equipment needs. Reach out to them at ttxservice@ttxinc.com.