A vibratory finishing machine deburring and polishing aluminum extrusions. All photos courtesy of Precision Finishing Inc.

Your vibratory finisher, vibe, tumbler, rumbler, shakers, polisher or however you might call it, is loud, messy and never works as it used to, right? It comes down to a few common issues that are likely keeping it from being reliable, producing repeatable results and becoming your all-time favorite machine.

The vibratory process has a handful of variables, each as important as the next. Media seems to get blamed for many of the issues surrounding this finishing discipline when really, the issue may be the process as a whole. When a vibratory machine goes unmaintained, time-cycles will increase, parts will become dull and dirty and dissatisfaction with the process can shy people away from utilizing vibratory machines to their full potential.

Featured Content

Media glazing

Glazed vibratory media

Glazed media can be a big reason for the loss of productivity in a vibe. Just like a grinding wheel, glazed media is designed to provide some surface-altering characteristics by means of abrasion. Without proper process controls, soils and contaminants will build upon the surface of the media, significantly reducing the effectiveness of the media.

This “glazing” can be attributed to improper compound selection, compound flow rates, part-to-media ratios, filtration/waste stream management, cycle times or machine setup.

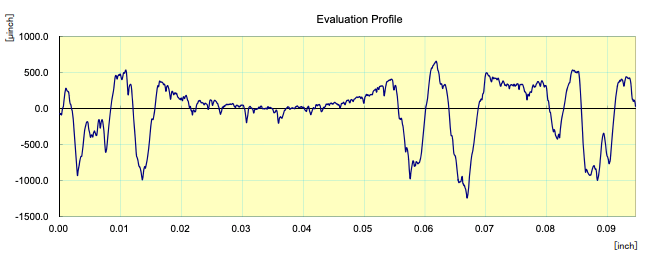

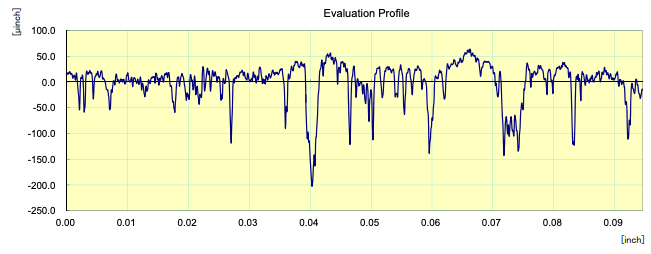

The media in this evaluation was a Washington Mills “C” bond, which is considered a “medium cut” media containing enough abrasive to do some surface refinement and deburring while maintaining a lustrous appearance. In this particular case, there is enough soil buildup on the media surface to effectively eliminate all deburring and refinement potential, resulting in exponential increases in time cycles as well as unpleasant finish quality. The graphical comparison below shows a roughness differential of over 200 µin between a properly conditioned media sample and a “glazed” media sample from an unmaintained vibratory process. You can also see a visible difference between the two.

Glazed media sample

Glazed media (left) shows a visual difference from conditioned media (right)

Reasons media becomes glazed

You will notice glazing propagates faster when the materials being processed are on the softer side, such as brass, copper, aluminum and some non-heat-treated steels. Processes containing high concentrations of manufacturing soils like greases and oils, high part-to-media ratios and low-quality metallurgical properties will produce a dark, concentrated waste stream, which should be an indication that a process audit should take place frequently.

High soil loads in vibratory wastewater will appear dark.

In a vibratory process, Some discoloration is to be expected, however, if your wastewater discharge appears dark and concentrated (see image at right), there is a high probability the media is glazed to some degree and should be monitored for productivity loss.

Proper compound dosing setup

As mentioned before, one reason for glazing can be improper chemistry selection and/or dosing methods. Chemistry selection is based on many factors, such as materials being processed, types of manufacturing soils and resulting finish requirements. Many times, we will find chemistry being used because “it came with the machine” or we get the “that’s what we use for everything” answer. Be sure the chemistry you’re using is appropriate for your application.

How to clean glazed media

If a process or wastewater restrictions require the drain on a machine to be closed, avoid extended time cycles that concentrate soils loads. Frequent filling and draining may be required to avoid re-depositing soils back onto the parts. Ideally, for a process that has high part loads, the drain should remain open and the fluid should be able to flow freely through the machine. This flushing action will allow the compound to carry out the media residue and soils, creating a clean finishing environment while increasing the luster and cleanliness of the part.

Cleaning glazed media can be fairly simple.

Cleaning glazed media is actually fairly simple. Burnishing compounds such as Chemtrol are designed to do just that. Consult with your chemistry supplier, and they can recommend the right cleaning chemistry to recondition media with proper cycle time and concentrations based on what your media is glazed with.

To use products like Chemtrol, use dosing pumps or batch processing to add to the media mass to begin emulsifying and dissolving residual manufacturing soils and metals. There is no standard cycle time for this process, however, with the right chemistry, you will start to see results in minutes. If your process is part-intensive and glazing can not be avoided, it is a good idea to incorporate media maintenance into your PMs.

RELATED CONTENT

-

Mastering Sanitary Stainless Steel Finishes

Here’s a primer on the types of finishes required for equipment used in sanitary applications.

-

Polishing vs. Buffing: What's the Difference?

Is polishing the same as buffing? Mechanical finishing expert, Pat Wenino, explains the differences between the two processes.

-

Making the Best Choices in Mass Finishing

Choice of equipment, media and compounds has a major impact on your finishing applications.