Published

PARTS CLEANING: Re-Thinking Precision Cleaning of Tools

A new cleaning line has eliminated manual scrubbing labor and increased throughput for Hardcoating Technologies as its commitment to quality has taken it from coating 67,000 cutting tools in its first year to more than 1.7 million over the next decade. The company now coats more than two million parts annually.

Cheryl Larkin, Northeast Regional Sales Manager, Miraclean

Hardcoating Technologies Ltd. was founded in 1996 because of quality issues, but the deficiencies of others have paid off big for the Munroe Falls, Ohio, company. Its commitment to quality has taken it from coating 67,000 cutting tools in its first year to more than 1.7 million over the next decade. The company now coats more than two million parts annually.

It all began with HTL’s sister company, SGS Tool Co., the first domestic cutting tool manufacturer to attain ISO 9001 status in the United States. SGS also is headquartered in Munroe Falls, where it manufactures a variety of cutting tools, drills, end mills, burs, reamers, routers, countersinks and specials that are sold in 66 countries.

Tools manufactured by SGS are used in manufacturing processes in industries such as aerospace, automotive, medical, power generation, foundry/casting, and mold and die. A key selling point and quality standard for these tools is the significantly increased tool life and production capacity that occurs when the tools are coated via physical vapor deposition (PVD) with a coating appropriate to their substrate and the operation they will perform.

Before 1996, SGS outsourced the coating operation to outside vendors, and the results were less than perfect, with coated tools too often coming back damaged. SGS’s solution to this problem was to create its own coating company with HTL to get the job done right.

Today, HTL offers four types of PVD coatings to SGS and more than 200 other customers in the U.S., ranging from tool manufacturers to tool distributors, and from end-users such as automotive, aerospace, medical, and mold and die, to tool re-workers and re-grinders. These coatings include HTL’s original, general-purpose coating, titanium nitride (TiN), plus three additional coatings: titanium carbonitride (TiCN); aluminum titanium nitride (AlTiN), the company’s proprietary formula and its most popular coating; and titanium diboride (TiB2), which HTL calls “the toughest coating ever, recommended for use with silicon aluminum alloys, titanium alloys, magnesium alloys and copper alloys.”

Precision Cleaning Challenges

According to HTL Vice President Bob Stauffer, the company coats tools 24 hours a day, five days a week. Precision cleaning—or what Stauffer calls “pristine cleaning”—is essential to the success of the process, as none of the coatings will adhere correctly on substrates that are less than scrupulously clean.

When HTL was first formed in 1996, it purchased an automated cleaning line featuring one 40-kHz ultrasonic cleaning station with caustic chemistry, one ambient plastic cleaning tank with acid chemistry, one 40-kHz ultrasonic rinse, two additional rinses (the final rinse being deionized water), a blow-off station and a re-circulating hot air dry. The system automation was a PLC-controlled hoist, but throughput was limited by the fact that the hoist stayed with a specific load at all times.

“As growth required it, we got around the hoist design and increased our production by manually stopping the line in the blow off station and re-starting it with a new load at the cleaning end,” Stauffer says. “Then we’d manually blow off the first load and move it to the dryer while the hoist automatically started the next load through the cleaning and rinsing, so that we could at least be working on two loads at once.”

Another challenge presented by the original cleaning line was that not all parts came out of it clean. Many of the re-worked and re-ground tools that arrived to be coated were heavily soiled, and some, such as rotary files, would come off the cleaning line with carbide swarf still stuck in the gullets of the flutes. This meant additional hand cleaning, which Stauffer estimates took one and a half to two hours per coating load.

With throughput demands growing, HTL looked to Miraclean Ultrasonics in Ashville, N.Y., to help develop a new, higher-production and more flexible machine. In addition to designing and building ultrasonic parts cleaning, passivating, electropolishing and anodizing lines, Miraclean is a division of Chautauqua Chemicals Co. and specializes in identifying and/or developing cleaning chemistries for specific applications.

Cleaning, Rinsing and Drying Solutions

Miraclean Technical Director Brian Sutton spearheaded his company’s side of the partnership to develop a more productive machine that would also eliminate the need for hand cleaning of tools already processed in the automated cleaning line.

A review of the tools to be cleaned in the line revealed that there were three categories of soiled instruments: lightly soiled new tools, heavily soiled re-worked or re-ground tools, and high-speed steel tools. Soils included oil-based grinding solutions, machining oils, polishing compounds, oxidation and grinding burns.

The cleaning detergent used in the original cleaning line was a high-caustic, chelated solution that sometimes failed to remove the soils from the tools and contributed to carbide leaching. Instead, Miraclean recommended a mildly alkaline, non-chelated chemistry that minimizes leaching and also splits oil. In conjunction with the cleaning-tank design, this split oil then is skimmed from the surface via a sparger and trapped in a separate overflow weir. Once in the weir, the oil can’t redeposit on clean parts on exit and is isolated for disposal.

To further improve the process, Miraclean outfitted the first alkaline cleaning tank with 25-kHz immersible ultrasonic transducers. This frequency is characterized by larger bubbles which implode more violently than the smaller 40-kHz bubbles, thereby supplying a cleaning action in the first alkaline tank that is more aggressive than the 40 kHz on the original line. Vertical agitation also was added to the first alkaline clean to provide additional mechanical action to break the soil bond on heavily soiled or steel tools.

Testing also indicated that adding a second alkaline cleaning station to the new line would give superior cleaning results. The second alkaline cleaning station was then equipped with 40-kHz ultrasonics. As a complement to the 25 kHz on the first cleaning station, the less aggressive but smaller bubbles produced by the 40-kHz ultrasonic frequency access tinier geometries to provide additional cleaning action. Both cleaning tanks are also equipped with electric heat, dual-filter systems to remove particulate and spargers to skim floating oils. In tandem, the two cleaning stations provide gross cleaning in the first cleaning station and fine cleaning in the second.

The acid cleaning station on the new line changed from a static, ambient bath on the original line to a third, heated ultrasonic cleaning station equipped with 40-kHz ultrasonics, electric heat, a filter system to remove particulate and a sparger system to skim surface oils into the separate overflow weir for disposal. The acid cleaner tested and proved by Miraclean is a milder pH acid that is safer to use, more environmentally friendly for disposal, and gives superior results in conjunction with heat and ultrasonics in removing oxidation and grinding burns.

Stauffer points out that, on the original cleaning line, the contents of the high-caustic cleaning bath and the low-pH acid cleaning bath had to be combined when drained to meet local effluent standards.

“The lower-pH alkaline chemistry and the milder acid cleaner on the new line now make this step unnecessary,” he says.

Next, Miraclean suggested three changes to the rinse tank configuration for the new line. First, the number of rinses on the line was increased. The original line featured a heated, double counter-flow (cascade) rinse after the caustic clean and a single heated DI rinse after the acid clean. The new line is equipped with two additional rinses, including an ambient rinse after the first alkaline clean and after the acid clean, and a triple counter-flow rinse at the end of the line. The triple counter-flow is to take advantage of the principles of dilution, with each added rinse improving dilution (and therefore reducing residue) exponentially. At the same time, the counter-flow feature means that the same water is being used three times, with conservation and cost-savings benefits. The counter-flow rinses are fed by HTL-supplied DI water for spot-free results.

The second change to the rinse configuration was from 40 kHz of ultrasonics in the first counter-flow rinse on the original line to 72 kHz of ultrasonics on the first counter-flow rinse of the new line. As Miraclean’s Sutton explains, 72 kHz is a still-gentler ultrasonic frequency that is especially appropriate for this application, providing the advantages of ultrasonic rinsing (driving solution into complex geometries) while minimizing the potential for damage from DI water, which can be aggressive on certain substrates.

The third change to the rinse tank configuration was the addition of a conductivity analyzer to the final rinse to call for fresh DI water when the quality in the last rinse dips below HTL-specified standards. This assures that the last water in contact with the tools is of acceptable quality without having to flow the rinse continuously and is further assurance of spot-free rinsing.

As on the original line, the final rinse is followed by an air blow-off station, but this was re-designed on the new line to eliminate problems that occurred on the original line. Stationary, side-mounted air knives have been replaced on the new line with an overhead moving air knife controlled by the PLC. HTL’s Stauffer—who was instrumental in the design—notes that the newly designed blow-off effectively removes water without blowing the parts out of their fixtures as sometimes happened with the side-mounted air knives on the old system.

“The blow-off is an important step to further decrease the chance of water spotting on the clean parts, which could result in coating rejects,” Sutton says. “The feed for the air blow-off is food-quality filtered air.”

The air blow-off station is followed by a re-circulating hot air dryer equipped with a HEPA filter to remove particulate. The dryer also has a connection for a nitrogen line to augment the drying, but the dryer has functioned efficiently without nitrogen to date, and HTL has never hooked it up.

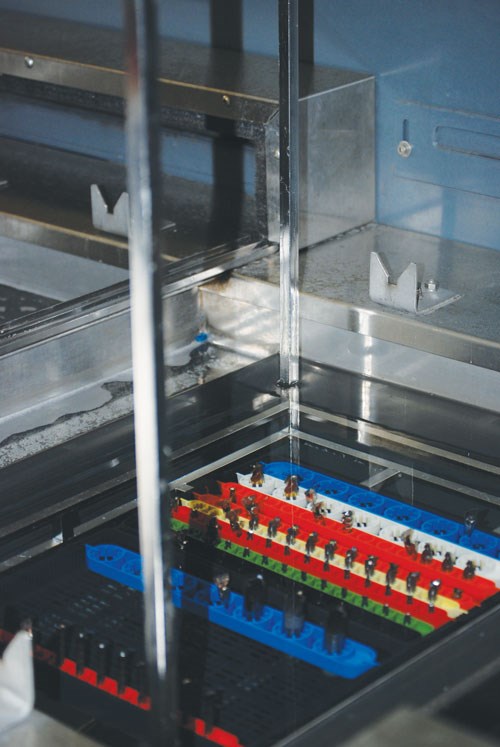

The Miraclean system’s standard automation package allows for three programs or recipes to run simultaneously, a feature which HTL uses regularly for the wide range of tools and soil levels that it has to clean. To protect the cutting edges of the tools from being cleaned, loads are processed as batches of tools fixtured in customized racks designed by HTL, which then fit into carriers supplied by Miraclean. This arrangement gives HTL great flexibility to respond to new types of tools, as new, part-specific racks can easily be integrated with the carrier system. At this time, HTL uses 60 to 70 modular racks, some plastic, some stainless steel, and more than 1,000 customized inserts in various substrates to hold the tools.

Feed and Speed

“Feed and speed is what coated cutting tools provide to their end-users,” Stauffer says. “In the cutting tool world, an appropriately coated tool can allow increased feed of product and speed of cutting up to 50 percent, and can increase tool life up to 10 times.”

“Feed and speed” is what the new Miraclean cleaning line has provided to the coating team at HTL as well. Since the installation of the line, manual scrubbing labor has been eliminated at a savings of four hours per day, 280 days per year, for a total savings of 1,120 hours per year. Throughput from the cleaning line has increased from 3,000 to 4,000 parts in 24 hours with the old line to 8,000 to 12,000 parts in 18 hours with the new line. Regular, rigorous tool inspections conducted by HTL show that tools are at least as clean as before, but now without hand cleaning.

As a bonus, the tweaking of recipes on the new cleaning line (chemistry, time and process steps) has resulted in reduced carbide leaching on affected tools, an important quality consideration, as leaching undermines surface quality, which in turn can lead to de-lamination (flaking, failure) of a coating that is subsequently applied.

HTL’s customers trust the results. One western U.S. manufacturer, for example, ships parts to HTL where they’re cleaned, coated, final-packaged and shipped directly to distributors—the ultimate nod to HTL’s quality control.

“Any time you can clean more parts and still maintain or exceed standards, you’re definitely moving in the right direction,” Stauffer says. “There has not been one tool failure or reject attributed to cleaning since the Miraclean system was installed.” n

Cheryl Larkin is East Coast territory manager for Miraclean Ultrasonics. She can be reached at 716-763-4343.

RELATED CONTENT

-

Conversion Coatings: Phosphate vs. Zirconium

Both phosphate-based and zirconium coatings have their advantages, but zirconium is fast becoming the pretreatment of choice.

-

Cleaning Limescale from Galvanized Steel

How do you clean white lime scale and rust spots on galvanize?

-

Are TGIC-Free Powder Coatings Right For You?

This alternative to TGIC-based polyester powder coatings offers similar performance and enhanced transfer efficiencies.