Published

Reducing the Chance of Spray Booth Fires

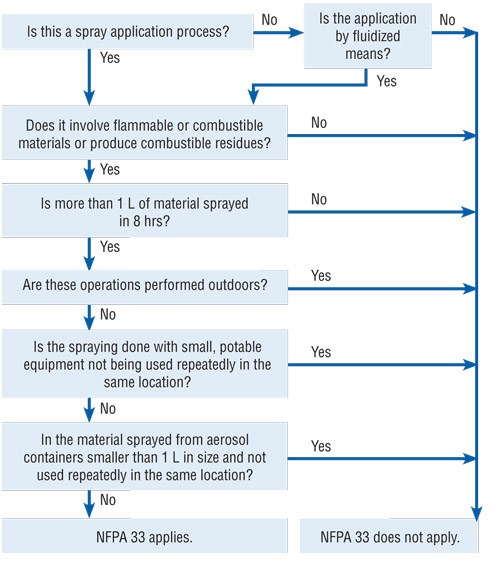

In the finishing industry, there is a real connection between safety and quality—especially when it comes to spray booths, which can run the risk of causing fire if not properly maintained. A review of basic safety precautions, plus a look at the National Fire Prevention Association standards that address fire safety in Spray booths.

Marty Powell, Industrial Territory Manager, Global Finishing Solutions

In the finishing industry, there is a real connection between safety and quality—especially when it comes to spray booths, which can run the risk of causing fire if not properly maintained.

Equipment for dust collection is strategically designed to meet specific needs in terms of performance, such as airflow velocity; fan, filter and burner capacity; and safety pertaining to fire prevention and operator wellbeing

However, once the manufacturer ships the equipment, installation, operator training and maintenance become the responsibility of the finisher. Therefore, it is best to give both the spray booths and associated processes a thorough review for fire safety hazards and other incidents that may occur.

Dust Collection

There are two sides of dust collection: quality and safety. A high quality finish is the direct result of adequate removal of airborne particles that may contaminate finished surfaces. This contamination causes rejects or rework of product that results in lost profits.

It’s not just surface finish that particle build-up can affect, though. If not cleaned, particles can migrate to areas where operators may not have proper breathing protection, and fire becomes a real hazard. Sufficient airflow is key.

The top causes of fire in dust collection systems include:

- static electricity discharge,

- exothermic reaction due to chemical reaction of collected dust,

- cutting or welding too close to the area.

The bottom line is to collect the dust with a well-designed dust collection system that incorporates a smart layout and balanced air replacement. As suggested by the National Fire Prevention Association (NFPA): “Air flow needs to be carefully considered.”

Criteria for dust collection processes usually include air velocity in the booth of 125 to 150 FPM. If properly filtered, this air can be recycled back into the facility. Fresh air dilution ratios for a facility also need to consider heat, off-gases, and odors from ancillary processes such as sanding or grinding.

In addition, doors or pressurized plenums can be used to contain dust. An investment in containment will be reflected in less money spent on cleaning and correcting finish rejects.

Other maintenance and follow-up recommendations:

- Know the correct codes and standards for your process. Go to NFPA.org to find your dust collect standards.

- Test your dust residue for flammability, especially for combined dusts.

- Ensure use of the correct filter media for your dust collection system.

- Keep the system clean.

- Eliminate static electricity.

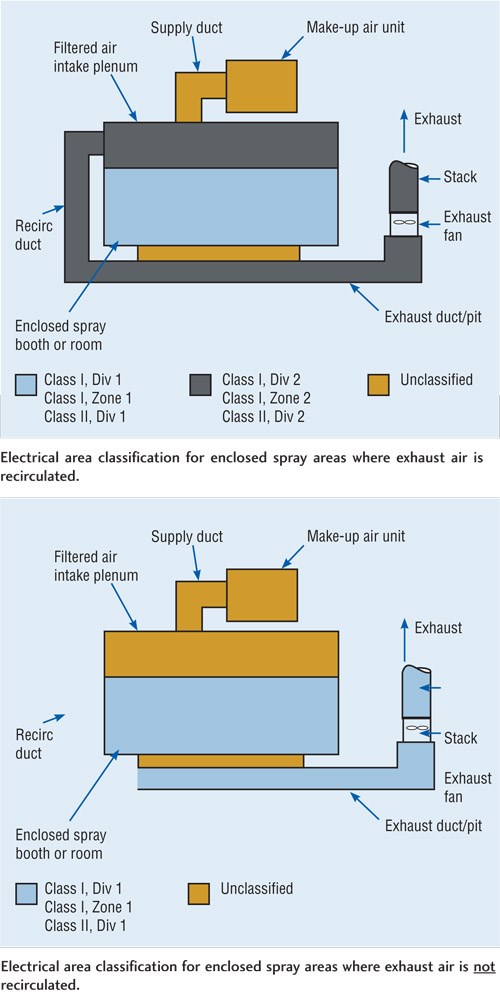

Spray Finishing Systems and Booths

Spray booths have a number of their own specific requirements for safety and quality. First, sufficient and laminar airflow is required so that the exhaust can capture overspray and pull it to the filtration systems, which can be either a dry filter or a water wash. To remove particulate from the air, the correct filter media or chamber is essential. Then, the fresh air supply needs to be not only clean, but also at the correct temperature. More sophisticated coatings may also require humidity control. And of course, all equipment needs to be properly grounded.

The best fire prevention may start with understanding of what can cause a fire in a spray booth.

In a conventional system, leading causes of fire include:

- using spark-producing equipment such as cutting, welding or grinding near the spray area;

- friction, in most cases caused by overheated bearings on the exhaust fan, or by rubbing of exhaust fan blades against overspray deposits on the wall of the duct;

- arcing electrical equipment;

- spontaneous combustion;

- and discharge of static electricity.

In electrostatic spray operations, leading causes of fire include:

- ungrounded or improperly grounded objects in the spray area,

- failure to fully discharge equipment before cleaning,

- pinhole leaks in the paint tubing to the spray gun,

- other causes similar to conventional systems such as smoking, cutting and welding.

All of these situations are entirely preventable, and some of them relate to maintenance in the spray booth, an issue called out in Chapter 10 of the NFPA 33: Standard for Spray Application Using Flammable or Combustible Materials. The section covers general maintenance requirements, removal of combustible deposits, maintaining high-pressure hoses, waste containers, clothing and cleaning operations amongst other very good information.

When spray booths and finishing equipment are installed, they meet the criteria for a quality job the first time through. It’s up to the shop to keep the system clean so that it meets that perfect, first-time performance every time. The system should allow for:

- proper airflow to get overspray into the filters instead of on the booth floor,

- and proper filtration to keep contaminants out of the air but also to prevent overspray buildup on the fan or in the exhaust duct.

For excellent prevention standards, keep your spray booth clean, change the booth filters regularly, check the fan and stack for buildup, guard against static electricity and read the NFPA 33 (available for purchase at short.pfonline.com/NFPA33).

Paint Curing or Drying Ovens

Infrared and convection ovens used for paint curing or drying are another obvious fire hazard in the shop. Again, the best advice is to always keep the area clean and provide adequate intake air. Remove combustible deposits, and to eliminate the risk of spontaneous combustion, make sure you have the correct exhaust volume and purge time. Keep solvent load in the oven below the “Lower Flammability Level,” and purge the oven before startup.

The same considerations for airborne contaminants should be applied to oven maintenance. Filtered recirculating air or filtered air seals can be critical, and both should be considered.

Airflow for ovens should have sufficient exhaust to evacuate solvent vapors and smoke. Also, analyze product conveyance and design the airflow of the oven to minimize stirring or tracking in dirt. Intake and discharge filters are available in many temperature ranges to fit any process.

Ovens, when used for what they are designed are for, are a very safe operation as most solvents are evaporated and other airborne contaminants and combustible deposits shouldn’t be present. It’s very dangerous when a convection oven is used for other means, such as to evaporate solvents by the drum-load, harden booth filters or ‘treat’ other waste deposits.

In summary, following recommended safety precautions will also ensure the highest quality production. The best advice is to know the safety standards and consistently follow them to the letter. Visit nfpa.org for regular safety updates.

Marty Powell is the Industrial Territory Manager for Global Finishing Solutions. He can be reached at 800-848-8738, ext 8063 or at Globalfinishing.com.

RELATED CONTENT

-

Understanding Paint Atomization

BASF coatings development expert Tim December explains how paint atomization works for both pneumatic spray applicators and high-speed rotary bell applicators.

-

Drivers of Change

Is your metal finishing software ready for an upgrade?

-

Is Your Electroplating Waste Hazardous?

Some that bears precious metals is, and there are a host of regulations to consider when recycling.