Source | Dürr Systems Inc.

The world’s automotive market is facing an oncoming revolution in the form of mass production of electric vehicles (EVs) as an increasing number of cars are powered by rechargeable batteries. Many component parts of today's automobiles stand to change or be replaced with the rise of EVs. As these changes come about, product and development engineers will not be the only ones required to pivot. Manufacturing engineers will face new challenges in adapting production methods to account for materials used in EVs, driven by a need for lightweighting. A greater volume of aluminum and its alloys will be used in the bodies of EVs with the goal of weight reduction, which will allow the cars to run longer with less energy while also reducing CO2 emissions.

According to studies conducted by the market reporting firm Ducker Worldwide (Troy, Mich.), changes in the material composition used in automotive bodies may contribute up to half of the total weight reduction of EVs. It has been estimated that, by the end of this decade, EVs will reach 550 pounds by weight of aluminum in their composition. In addition to lightweighting, the anti-corrosive and thermal properties of aluminum make it well suited for battery structures.

Featured Content

For surface treatment in automotive industry paint shops, such an increase in aluminum in vehicle bodies will affect the paint-curing process for ecoat primer and topcoat. It will also affect the ovens used for curing sealants and heating wax in cavities as well as cooling tunnels.

Pre-treatment, phosphating and electocoating processes may also be affected by changes in the composition of electric car materials. Different compositions of the vehicle bodies can change the thermal balance of the baths, which must have their fluid temperature-controlled. Consumption of utilities as chilled water, hot water and gas will likely need to be re-evaluated, as will heater exchanger systems. However, most modifications in painting and application processes will likely be seen in curing ovens and cooling tunnels, which is the focus of this article.

Aluminum’s specific heat (thermic inertia) is approximately 80% greater than steel’s. In some cases, depending on the composition of a vehicle body, the reduction of mass with the substitution of aluminum in place of steel may reduce or mitigate the need for a higher thermal density of the oven. However, aluminum will be increasingly present in complex areas, such as rocker panels, pillars and other high-density parts. Such areas are difficult for convection air to access during curing, resulting in the need for increased curing time in order to reach required temperatures. In addition, adhesive products used in the assembly of the car bodies can be another factor that demands certain temperatures be reached. Most ovens currently use the convection principle to ensure the substrate reaches the temperatures required by paint manufacturers. The greater the convection, the more efficient the heat transfer process.

For process engineers who use Datapaq thermal profiling systems to assess and monitor the effectiveness of the curing process, an increase in the gap between air temperature and substrate temperature in specific areas mentioned above will occur more frequently. When this happens, two measures must be taken in order to fulfill the curing processes: a) improving the impingement (impact) of the convection air on the substrate; b) increasing the curing time or oven temperature if the level of production is constant. It is important to remember that the same measures must be observed in cooling, which will present the same challenges inversely.

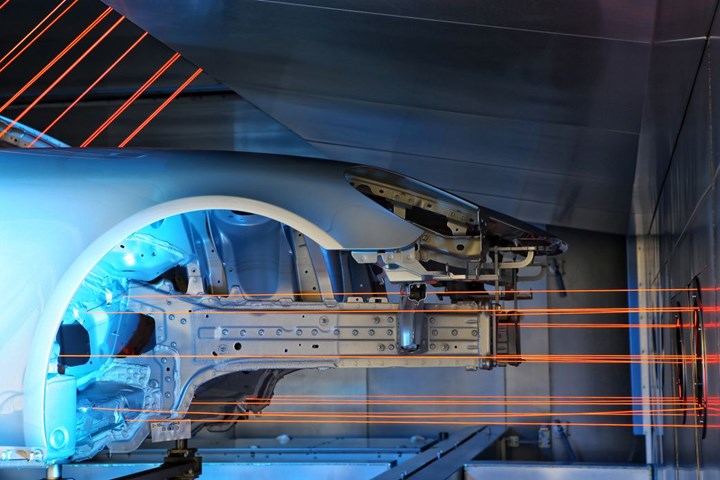

For a better impingement of the air recirculated by the heating boxes, the ovens may have their nozzle walls changed. A correct optimization of these nozzles requires analysis in order to increase speed and, consequently, increase the impact on the substrate. One must take into account the oven’s fans (pressure and flow). Studies show that larger-diameter nozzles help to improve convection in areas with difficult air impact. The modification of the internal sidewalls of the oven is an alternative to improve the process. In addition, one must observe the recirculation density, which, put simply, is the ratio between flow and the measure of the length of the continuous oven. Values above 550 standard cubic feet per minute (scfm) per foot are sought for conventional ovens — for cooling tunnels values, the desired value is above 900 scfm per foot. In addition to the sidewalls, depending on the heating deficit of the lower parts of the bodies, as rockers, it is possible to evaluate the installation of lower nozzles that are directed to these areas of thick profiles. However, analysis is necessary to determine whether there is sufficient air density. In most cases, it is necessary to add a heating box to avoid compromising the flow of the side nozzles. Another possible change is the implementation of larger-diameter nozzles at the top of the side panels and consequent patch nozzles in other areas of less demand. Nozzles with predetermined angles that allow air to be directed into the car bodies through the window openings can be used. This brings better air convection inside the bodies, where lower-temperature air bubbles tend to form and impair the heating curve of the substrate exactly in the areas where the aluminum is being used.

Nozzles with predetermined angles that allow air to be directed into the car bodies through the window openings can be used. Source | Dürr Systems Inc.

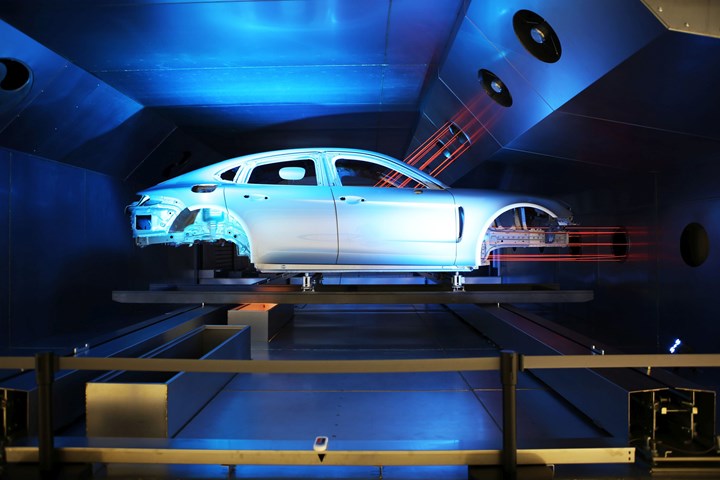

Additionally, concerning improvement in air impingement, there are new technologies being developed and applied with the concept of transporting the vehicle bodies inside the oven. These ovens, known as transversal ovens because of their orientation, are specifically designed to improve the heat transfer in internal areas and where thickness and mass are higher. By orienting the vehicles crossways, these transversal ovens enable the direct inflow of hot curing air into the windshield opening and effectively heat the vehicle bodies “from the inside out.” The ovens are equipped with large nozzles at the top and bottom sides which point toward the front window and bottom front of the vehicle body. The concept is said to deliver an improved topcoat appearance.

Transversal ovens such as the DürrEcoInCure are a fundamentally new concept in vehicle drying that allows the vehicle bodies to be heated from the inside out. Source | Dürr Systems Inc.

The second factor to consider is the need for more effective oven time. The thermal inertia of the materials limits the efficacy of the direct increase in the thermal capacity of the ovens. This means that, even if the heating power of burners is increased or new units are added, it will be necessary to increase the oven time. The heating curve will not change linearly with the increase in calories injected into the system. As a result, longer time and longer tunnels are often the only solution. In ecoat ovens, where temperatures tend to be higher and where there is still a need for dehydration due to the dip painting process, the use of aluminum in vehicle bodies demands even more of the equipment. Unfortunately for those plants that have space limitations or cannot effectively increase the length of the oven, this can prove difficult. Often, the solution involves expanding the building or reducing areas that precede the oven, which can compromise other aspects of the process. With an increase in oven length comes the need to add heater boxes to maintain the recirculation flow ratio, heat a greater volume of air and balance the existing thermal losses. As mentioned earlier, transversal ovens might be a solution to consider since they need a shorter length. In all cases of expansion, additional changes to the conveyor system must be taken into account.

One thing is certain: The advent of EVs will bring new manufacturing plant needs. Careful evaluation of existing technology and new solutions will be necessary as everyone involved in making these new vehicles moves forward. What will it mean for your surface finishing operation?

RELATED CONTENT

-

Reducing Powder Coating Waste

Coating application is often overlooked as a potential money saver, but recognizing opportunities within this area is crucial to an efficient operation.

-

The Powder Coating Process

Powder coating is one of the most durable finishes that can be applied to industrial manufactured products, and offers excellent corrosion protection and is very safe because of its lack of volatile organic compounds. To understand the powder coating process you should start with the fundamentals.

-

Troubleshooting Bubbles in Powder Coating

How can I get rid of these bubbles in powder coating?