The Importance of Benchmarking Your Application Parameters

Having repeatability issues in your coating process? John Owed of Carlisle Fluid Technologies discusses the importance of benchmarking your application parameters in order to identify and quickly resolve problems.

#ask the expert

Q: We upgraded from a manual to an automatic spray system, understanding that it would improve the repeatability of our finishing process. However, we continue to chase issues related to our process, such as low film builds and poor appearance like orange peel, mottling, and stripping. What are we missing?

A. The situation described is common and directly related to benchmarking the application parameters at start-up and understanding how various settings interact and impact each other. You mentioned an automatic spray system but did not note if this was hard automation (multiple applicators on a machine) or flexible automation (single applicator on a robot); regardless, the following response would apply.

Featured Content

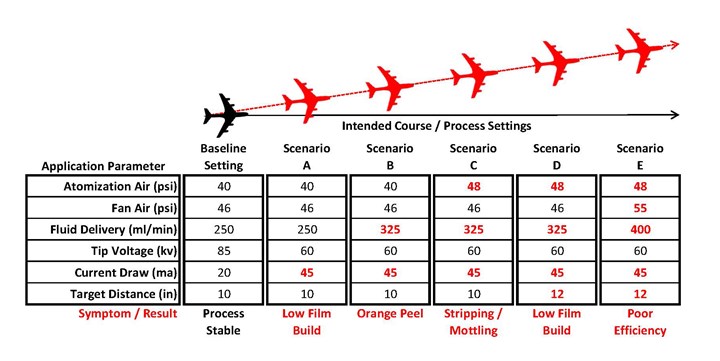

The example below shows a typical process with the most critical application parameters. Usually, at start-up, the system is optimized to meet the original design parameters related to cycle time and finish quality, including coverage, film build, and appearance. At this point, the process is documented, and the benchmark settings are recorded and yielding a “stable process.”

What often happens is things begin to go awry. If the benchmark settings are recorded, and a comparison can be made, then problems can be quickly identified and resolved. If there is no reference point, then people begin reacting to the symptoms instead of identifying the root cause of the problem.

In reference to the figure/chart below:

- Baseline Settings: Process is stable, and good products are manufactured.

- Scenario A: Low film build on the finished parts is detected; operators increase the fluid flow rate to increase film thickness

- Scenario B: Finished parts have increased orange peel; operators increase atomization air to create smaller droplets and improve finish quality.

- Scenario C: Finish quality is not acceptable due to stripping and mottling; operators increase target distances to get a larger spray pattern.

- Scenario D: Low film build on the finished parts is detected; operators increase fluid flow rate and increase fan air.

- Scenario E: Purchasing notices that paint usage has drastically increased and seeks out the paint line manager.

Scenario A – D can play out in a matter of hours or days. If you get to scenario E, the process has been off for weeks to months!

Conclusion: had the operator immediately referred to the benchmark settings, they would have noticed the increased current draw caused the tip voltage at the applicator to drop, resulting in lower transfer efficiency. This root cause problem could have been resolved and may have been as simple as cleaning a contaminated component or verifying resistivity of the coating material.

Process benchmarking

Photo Credit: Carlisle Fluid Technologies

In addition to the parameters noted above related to the applicator, there are other items to consider that impact the finishing process:

- Environmental factors including:

- Ambient temperature & humidity

- Air flow in the spray booth

- Impact of filter loading on air flow.

- Process:

- Variations in part temperature as it enters the application area:

- Conveyor speed increases or decreases.

- Coating related:

- Viscosity/Temperature

- Solids content

- Coating formulation (fast versus slow evaporating solvents)

- Resistivity

The more items you can identify and benchmark that directly or indirectly impact your process, the greater your ability to identify the root cause and correct when things go awry. In some cases, it reminds me of an electronic device or app that you have had for a while. Periodically, you need to reset to the factory/original settings. In the case of a finishing system, you need to benchmark those settings at start-up and occasionally hit the restore button.

About the Author

John Owed

John Owed is the finishing SBU director at Carlisle Fluid Technologies. Visit carlisleft.com

RELATED CONTENT

-

Mitigating Inconsistencies From Liquid Coating Tank Changes

Mike Bonner of Saint Clair Systems discusses strategies for keeping liquid coatings homogenous and mitigating inconsistencies when changing process drums.

-

How to Avoid Mud Cracking

Julie Holmquist of Cortec Corporation discusses ways to avoid mud cracking defects when applying anticorrosion coatings.

-

Reinventing Paint: Aero Decorative Films

Advanced film technology said to be more durable, less costly, and greener than spray paint.