EVs

Photo Credit: Getty Images

The debate over the viability of electric vehicles is an age-old one relating to the automotive industry. EVs are anything but new — in fact, some of the first cars built ran on electricity. Various automakers throughout history have taken an occasional run up at creating an electric car for the masses only to be met with skepticism at best. But, times have changed.

The last few years have had a ramp-up in sales of EVs and hybrids — sales have quadrupled over the past seven years. Currently, EVs and hybrids make up 10% of the market in the U.S. By 2025, it is projected they will command almost 50% of the market. By 2030, ICE vehicles are expected to only make up about 12% of the market.

Featured Content

So, where do the opportunities for finishers lie in the increasing production of these vehicles? We turned to some of the experts at MacDermid to hear about the solutions they are exploring with their customers — both OEMs and tier suppliers.

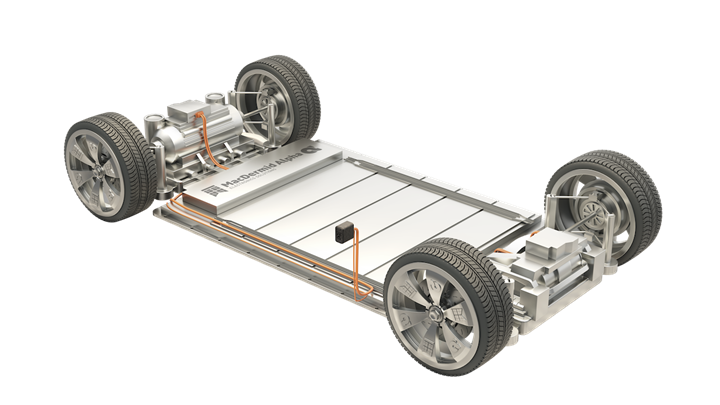

Designing powertrains for EVs is an area ripe for finishing innovation.

Photo Credit: MacDermid Alpha

Finishing opportunities

At the October 2022 Electroless Nickel Conference, Doug Hughes, North American Product Manager, Wear Resistant Coatings, for MacDermid Enthone Industrial Solutions, gave a presentation titled “The Rise of the EV” that discussed some of the areas that hold opportunities for finishers. One of the important things that Hughes noted is that so much of how EVs are being built is in a stage of continuing development. The ramp-up in the electrification of vehicles presents a whole new set of puzzles to solve for automakers and tier suppliers. Various components within electric motors need to be conductive or insulative and the industry hasn’t fully converged on the solutions that will enable those applications. Constant innovation and refinement is happening right now. And OEMs and tier suppliers are more open to collaboration than they’ve been for a long time.

“Electric vehicles are still in their infancy when it comes to technological innovation,” Hughes says. “Tesla set the bar really high, but they’re still in their infancy.”

So what applications are we looking at when it comes to finishing used to enable EVs? Granted, there is a lot of electronic chemistry that figures into many areas from smart screens to autonomous technology sensors, but much of the opportunity for finishers lies in the powertrain of the vehicle itself. While EV powertrains involve roughly 60% fewer components than their ICE counterparts, there is a vital need for conducting current and thermal management. Designing powertrains for EVs is an area ripe for finishing innovation.

Chris Klok, director of vehicle electrification for ESI Automotive and MacDermid Alpha Electronics Solutions, explains, “The electric powertrain is quite basically a construction of power electronics, which is the main inverter, the DC-DC converter in the onboard charger, then there’s a battery pack and one or more electric motors.”

Obviously, for an electric-powered vehicle, you need to move more current than in traditional powertrains. MacDermid’s EV Portfolio includes finishing solutions for many of the electronics including DBC/AMB substrates, heatsinks, lead frames, connectors and busbars.

Busbars and connectors

Busbars provide a lot of advantages when it comes to EVs. In addition to carrying more current by dimension compared to cables, they also increase the design diversity. The ability to be formed at precise angles allow them to fit closely with vehicle profiles and they also aid in providing rigidity for the entire battery module.

“Busbars give the carmaker a lot of liberty in constructing certain designs because you can make very sharp angles which is not possible with cables,” Klok says. “You can also implement automation in your production line with busbars, which you cannot easily do with cables and connectors. You typically need labor for assembling those.”

Busbars are typically screwed to the electronics and rely on plating to increase connectivity and corrosion protection.

“Active programs are underway to address the best ways of coating busbars,” Klok says.

Heatsinks

Thermal management in EVs is of utmost importance and heatsinks are a huge area of interest for finishing solutions. Heatsinks transfer the heat generated by an electrical device to a fluid coolant that allows the heat to be dissipated.

Steve Wilde, automotive OEM director at MacDermid Alpha, explains that heatsink base plates get bolted into a housing where glycol passes through pin fins on the underside of the heat sink base plates, which pull heat away from electronic components on top of the assembly.

“You have very powerful electronic components and the heat has to be taken out — it’s drawn through the plating, through a thermal interface material (TIM),” Wilde says. “So we’re plating this mainly so we can attach securely, successfully and with good thermal and electrical properties. Plating enables adhesion, it enables thermal transfer and improves electrical conductivity.”

Klok adds, “Some of these heat sinks, see an assembly step — and by that, I mean either soldering or sintering. And for sintering, you need a silver finish on top. So, we see some selective plating on heat sinks.”

Wilde goes on to explain that sintering is able to transfer heat much better than soldering. MacDermid provides a silver nanoparticle product known as Argomax that enables sintering of power modules to aluminum heatsinks. But the Argomax cannot adhere directly to the aluminum.

“Without those plated layers, we couldn’t sinter,” Wilde says. “Everything works in a system — plating made that happen.”

A time of innovation

As Wilde points out, it’s important to keep in mind that material combinations within EV systems dictate the finishes needed. The above examples are just two of the areas where finishing plays a role. Solutions are also being used in batteries, e-motors and housing for electronics, to name a few. And while industrial solutions aren’t as called for as electrical ones, they play a key role.

Going back to something Hughes said earlier, it’s important to stress that the mass production of EVs is still in its infancy. Innovation is happening before our very eyes and finishing has a key role to play in continuing to develop the next generation of vehicles that will be on the road. The need for collaboration at the design stage is very real.

Of course, there are still plenty of hurdles to overcome as production levels of EVs increase. Historically, roadblocks to EV adoption have included concerns over range and a lack of infrastructure — charging stations and investments in energy — to support mass adoption. Yet all of that can also translate into opportunity for manufacturers and finishers as well, as investments are made in building the charging stations needed to support the increasing number of EVs and hybrids on the road.

“The story hasn’t been fully written yet,” Hughes says. “The finishing opportunities in this space are growing. If you’re not pursuing these opportunities, start pursuing them now. It’s better to get in now than to wait and be on the outside looking in.”

RELATED CONTENT

-

The History of Electroplating and A Historical Review of the Evolution of NASF

The history of electroplating is a curious mixture of mistakes, observations, serendipity and experimental development, enmeshed and entwined with the discovery of electricity in the late 18th century. Join Mr. Nebiolo as he reviews the fascinating history of our industry and its metamorphosis during the last 238 years. He will also provide a brief history of our flagship society, the NASF.

-

NASF/AESF Foundation Research Project #120: Electrochemical Destruction of Perfluorooctanesulfonate in Electroplating Wastewaters - April 2022-March 2023

This NASF-AESF Foundation research project report covers project work from April 2022 to March 2023 at the University of Illinois at Chicago. The overall objective of this work is to utilize a cost-effective reactive electrochemical membrane (REM) for the removal of PFAS from synthetic electroplating wastewater. Initial results for the oxidation of PFOA with three different catalysts are discussed.

-

Electroplating for Medical Devices

Brittany McKinney of Pavco Inc. discusses the benefits of electroplating for medical devices.